Home » Packaging Solutions Designed for Cost Effectiveness

Packaging Solutions Designed for Cost Effectiveness

When it comes to packaging, cutting costs doesn’t mean cutting corners. The most cost-effective packaging solutions are those that balance performance, simplicity, and scalability. Whether you’re shipping direct-to-consumer, distributing through retail, or moving industrial product in bulk, your packaging should protect your product, support your brand, and save you money at scale.

Here are some of the most cost-effective packaging products—and why they’re worth considering.

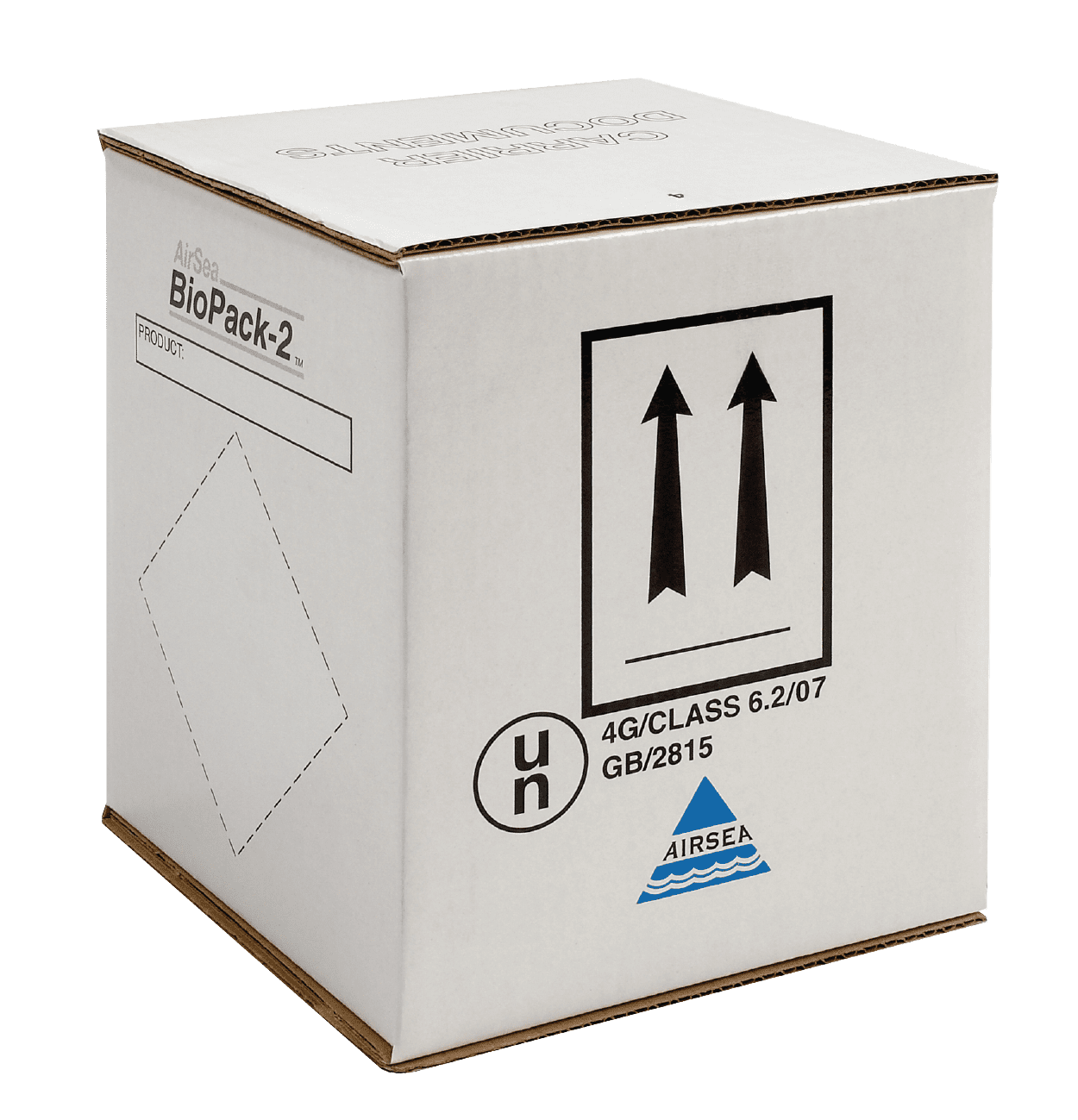

Corrugated Boxes

Why it’s cost-effective:

Corrugated boxes are one of the most affordable and versatile options for shipping and storage. They’re lightweight, recyclable, and available in a wide range of sizes and strengths. Standard box styles like RSC (Regular Slotted Containers) keep production costs low and lead times fast.

Best for:

- E-commerce shipping

- Industrial parts

- Retail master packs

Folding Cartons

Why it’s cost-effective:

Folding cartons use less material than rigid boxes, collapse flat for efficient shipping, and run easily through automated packing lines. They’re ideal for low to mid-weight items and are highly customizable for retail.

Best for:

- Food, beverage, and supplements

- Cosmetics and personal care

- Pharmaceuticals

Poly Mailers

Why it’s cost-effective:

For soft goods or items that don’t require structural protection, poly mailers are inexpensive and lightweight. They also help reduce dimensional shipping weight, saving money in both materials and freight.

Best for:

- Apparel and textiles

- Accessories

- DTC shipping

Roll Stock (Flexible Film)

Why it’s cost-effective:

Roll stock is efficient for high-volume production and automated packaging environments. It’s commonly used for pouches, snack packs, and sachets. By forming packaging on demand, it reduces waste and speeds up fulfillment.

Best for:

- Snacks and dry goods

- Single-serve products

- Promotional sample packs

Kraft Paper and Fill

Why it’s cost-effective:

Kraft paper and void fill are low-cost ways to protect products inside a box without using foam or molded inserts. Paper-based solutions are recyclable and easy to source.

Best for:

- Light cushioning and bracing

- Eco-conscious shipping

- Variable product sizes

Die-Cut Inserts (Chipboard or Corrugated)

Why it’s cost-effective:

Custom inserts made from chipboard or corrugated reduce product movement in transit and eliminate the need for bubble wrap or expensive molded foam. They also improve unboxing and reduce returns from damage.

Best for:

- Multipacks

- Fragile or breakable items

- E-commerce kits

Bulk Packaging & Pallet Solutions

Why it’s cost-effective:

For large or industrial products, bulk corrugated bins, Gaylord boxes, and edge protectors reduce labor and material use. These solutions are reusable and help consolidate shipments.

Best for:

- Industrial and automotive parts

- Warehouse-to-warehouse movement

- Heavy or oversized loads

Final Thoughts

Cost-effective packaging isn’t about going cheap—it’s about using the right material, structure, and design for your product and distribution channel. With smart packaging choices, you can reduce freight, simplify fulfillment, and protect your margins without sacrificing quality.

Want help building a cost-effective packaging solution?

We’ll help you identify the most efficient products for your needs—whether it’s simple shippers, optimized inserts, or custom print-on-demand solutions.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » Packaging Solutions Designed for Cost Effectiveness