Home » Packaging Shippers: An Essential Component of the Supply Chain

Packaging Shippers: An Essential Component of the Supply Chain

In the world of logistics and product distribution, packaging shippers play a crucial role. They are the backbone of ensuring that products reach their destination safely and efficiently. This blog post aims to shed light on what packaging shippers are, their importance in the supply chain, and the various types available to cater to different shipping needs.

What are Packaging Shippers?

Packaging shippers refer to the containers or materials used to ship products from manufacturers to retailers or directly to consumers. They are designed to protect goods during transit, handling, and storage, ensuring that products arrive in pristine condition. The effectiveness of packaging shippers is vital for maintaining product integrity, customer satisfaction, and a brand’s reputation.

Importance of Packaging Shippers in the Supply Chain

- Protection: The primary function of packaging shippers is to protect the contents from damage during transportation, whether from physical impact, environmental factors, or other hazards.

- Efficiency: Well-designed shippers can significantly improve the efficiency of loading, unloading, and transporting goods, thereby reducing costs and saving time.

- Compliance: They ensure compliance with shipping regulations and standards, which can vary depending on the mode of transport and the nature of the products being shipped.

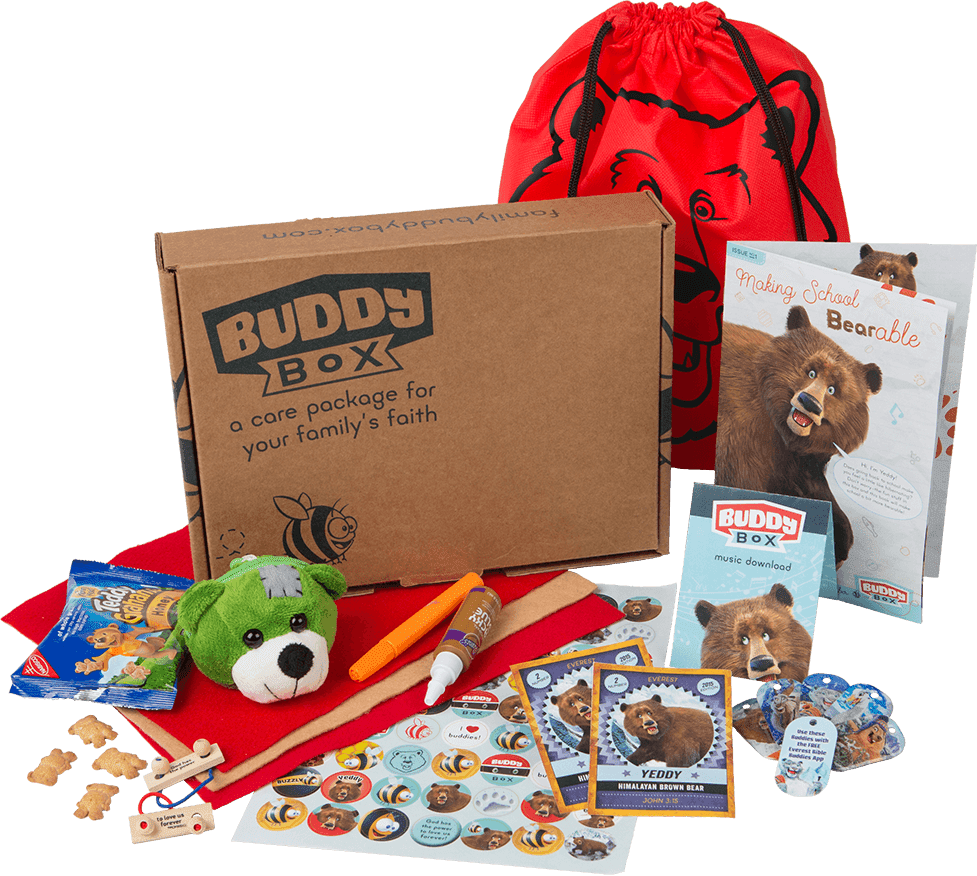

- Brand Representation: Packaging shippers can also serve as a branding tool, especially when shipping directly to consumers. Branded packaging enhances brand visibility and can improve the customer unboxing experience.

Types of Packaging Shippers

The type of packaging shipper used depends on the product’s characteristics, the shipping method, and the required level of protection.

Corrugated Boxes:

- The most common type of packaging shipper.

- Offers a balance of lightweight design and strength.

- Can be customized in size, shape, and strength.

Padded Mailers:

- Ideal for small, lightweight items.

- Provides cushioning and protection for items that do not require a box.

Crates and Pallets:

- Used for bulkier and heavier items.

- Facilitates easy handling and storage, especially for international shipping.

Custom Shippers:

- Designed specifically for products that require special handling or protection, such as electronics or fragile items.

- Can include features like insulation, waterproofing, or reinforced walls.

Eco-Friendly Options:

- Sustainable packaging solutions like biodegradable or recyclable materials.

- Appeals to environmentally conscious consumers and aligns with green business practices.

Choosing the Right Packaging Shipper

Selecting the appropriate packaging shipper involves several considerations:

- Product Needs: Assess the level of protection required based on the product’s fragility, size, and weight.

- Shipping Method: Consider the mode of transportation (air, sea, road) and its specific requirements.

- Cost: Balance the cost of packaging materials with the level of protection they provide.

- Environmental Impact: Consider the sustainability of the packaging materials and their lifecycle.

Innovations in Packaging Shippers

Advancements in packaging technology have led to the development of smarter and more sustainable shipping solutions. Innovations include improved cushioning materials, temperature-controlled shippers for perishable goods, and smart packaging with tracking capabilities.

If you are interested in packaging shippers, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Packaging Shippers: An Essential Component of the Supply Chain

Why Packaging Strategy Matters Packaging is more than just a protective layer—it plays a vital role in branding, marketing, and customer experience. One of the

Millennials, born roughly between 1981 and 1996, have become a dominant force in the consumer market. Their unique preferences and values significantly influence packaging trends.

Corrugated boxes are strong because of their unique construction, which features a fluted corrugated sheet sandwiched between two flat linerboards. This design creates a robust