Home » Packaging on a Budget: Strategies for Reducing Your Business’s Packaging Costs

Packaging on a Budget: Strategies for Reducing Your Business’s Packaging Costs

In today’s competitive market, businesses need to constantly look for ways to cut costs and increase efficiency to remain profitable. One area where businesses can save money is in their packaging costs. Packaging is an essential part of any business, but it can also be a significant expense.

In this guide, we will explore some tips and strategies that businesses can use to reduce their packaging costs, as well as the potential tradeoffs that come with those savings.

Cost Reducing Packaging Strategies to Use

Right-Size Your Packaging

To right-size your packaging, businesses should take accurate measurements of their products and choose packaging that fits those dimensions, leaving just enough space to protect the product. Using packaging that is too large can waste materials, increase shipping costs, and take up unnecessary space. Choosing the right size packaging can save businesses money on materials and shipping costs while reducing their environmental impact.

Use Lighter Weight Materials

Choosing lighter weight packaging materials can significantly reduce the cost of materials, shipping, and energy used during production. For example, switching from a traditional corrugated box to a padded envelope or lightweight mailer can save on materials, weight, and shipping costs. Businesses can also consider using eco-friendly materials like recycled plastic, paper, or biodegradable materials that are lighter and cost-effective.

Optimize Your Packaging Design

Businesses can optimize their packaging design by selecting packaging that is durable, easy to use, and visually appealing. By using a unique design that fits the product, businesses can reduce the amount of material needed, use more cost-effective materials, and reduce shipping costs. Additionally, using packaging that is easy to open and store can reduce the likelihood of damaged products and improve customer satisfaction.

Use Sustainable Materials

Switching to sustainable materials like recycled plastic, paper, or biodegradable materials can reduce costs and improve sustainability. While sustainable materials can be more expensive, businesses can reduce costs by purchasing in bulk, using eco-friendly packaging designs that require fewer materials, and sourcing materials locally to reduce shipping costs. Sustainable materials can also help businesses appeal to customers who are environmentally conscious.

Buy in Bulk

Purchasing packaging materials in bulk can help businesses take advantage of volume discounts, reduce shipping costs, and ensure they have enough packaging on hand for peak sales seasons. Buying in bulk can also help businesses negotiate better pricing, improve lead times, and reduce the risk of running out of materials when demand increases.

By implementing these strategies, businesses can reduce their packaging costs without sacrificing quality, sustainability, or customer satisfaction. However, it is essential to consider potential tradeoffs and weigh the benefits of each strategy to determine which is best for their unique business needs.

Potential Tradeoffs To Cutting Packaging Costs

Quality

Reducing packaging costs can sometimes lead to lower quality materials, which can impact the appearance and safety of the product. Using low-quality packaging materials can result in damaged products, increased returns, and harm to a brand’s reputation. Therefore, businesses should consider the balance between cost savings and the quality of packaging materials to ensure they are not sacrificing quality for cost savings.

Sustainability

While sustainable packaging materials can reduce a business’s environmental impact, they can be more expensive than traditional packaging materials. Therefore, businesses must weigh the benefits of sustainable packaging against the higher costs. Choosing sustainable materials can help businesses appeal to environmentally conscious customers, but it is essential to ensure the cost is reasonable and the materials provide the necessary protection for the product.

Brand Image

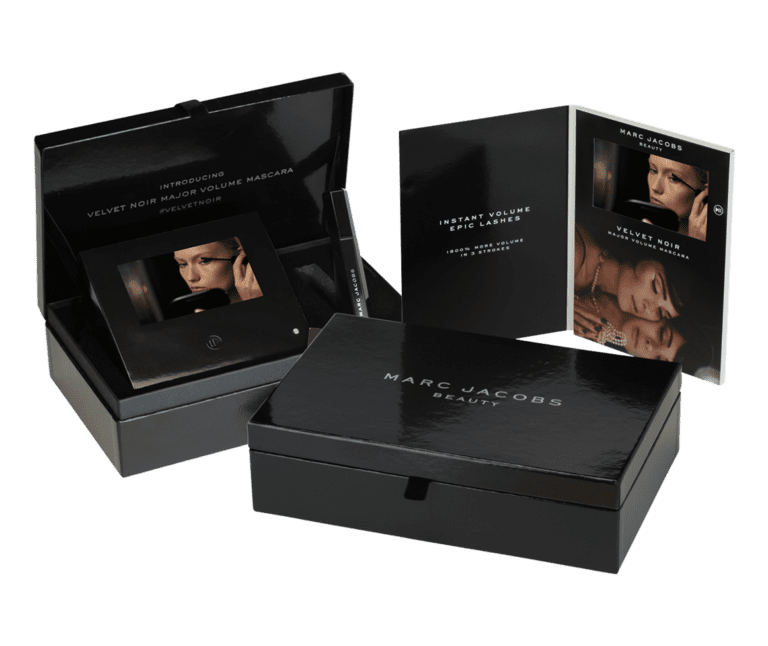

Packaging plays a critical role in shaping a brand’s image. Choosing packaging that is low quality or visually unappealing can negatively impact a brand’s image and harm sales. Therefore, businesses should consider the potential impact of packaging changes on their brand image and take steps to ensure they are not sacrificing brand image for cost savings.

Customer Satisfaction

Packaging is often the first impression customers have of a product. Poor quality or unappealing packaging can negatively impact customer satisfaction and harm a brand’s reputation. Therefore, businesses must consider the potential impact of packaging changes on customer satisfaction and ensure they are not sacrificing customer satisfaction for cost savings.

Summary: Cutting Packaging Costs and Tradeoffs

In conclusion, reducing your packaging costs can provide many benefits for your business, including cost savings, increased efficiency, and improved sustainability. However, businesses need to carefully consider the potential tradeoffs and balance cost savings with the need to maintain quality, sustainability, and brand image. By taking a strategic approach to packaging, businesses can reduce their costs without sacrificing quality or customer satisfaction.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Packaging on a Budget: Strategies for Reducing Your Business’s Packaging Costs

Packaging is a crucial aspect of any business that deals with physical products. Custom die-cut foam is a popular packaging material that offers excellent cushioning

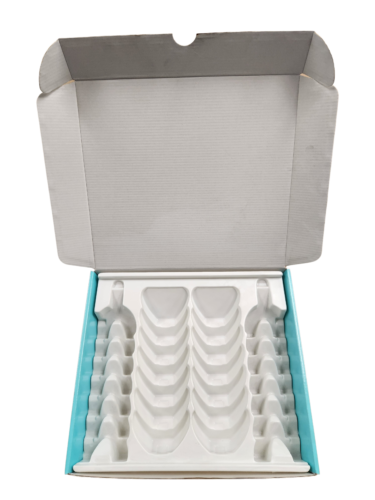

Custom box inserts are used to ensure your products are secure inside your box throughout the supply chain. They are used to keep your product

In the world of packaging, different products require different packaging solutions. With myriad options available today, companies can be selective about which suits their needs