Home » Packaging Dieline With Artwork: What Should Be Included?

Packaging Dieline With Artwork: What Should Be Included?

Packaging is more than just a means to protect and transport products. It is a powerful tool for brand recognition, customer engagement, and conveying product information. One of the foundational elements of effective packaging design is the packaging dieline.

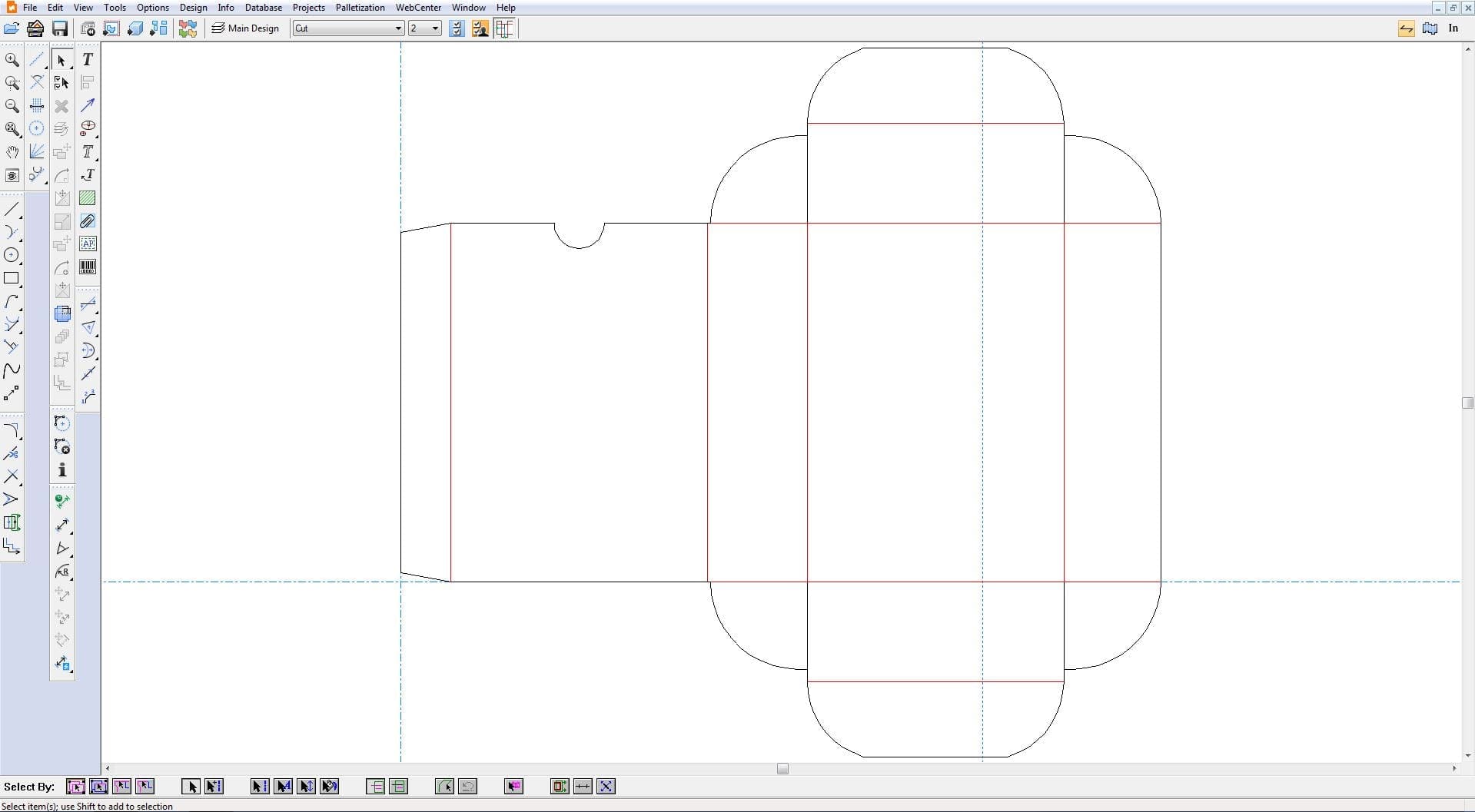

What is a Packaging Dieline?

A packaging dieline is a two-dimensional blueprint or template that outlines the structure and dimensions of a product’s packaging. It serves as a guide for designers, manufacturers, and printers, ensuring that the packaging design aligns with the intended dimensions and specifications. Think of it as the architectural blueprint for your product’s packaging, offering precise measurements, cut lines, and folding instructions.

Why is a Packaging Dieline Important?

- Accuracy: A packaging dieline ensures that the final product matches the intended design. It provides exact measurements and cut lines, reducing the risk of errors during production.

- Cost-Efficiency: By providing precise specifications, dielines help reduce material wastage and production costs. Efficient designs also enable easier assembly, saving time and labor costs.

- Consistency: Dielines establish a consistent design framework, making it easier to maintain brand identity across various products and packaging formats.

- Communication: It acts as a visual communication tool between designers, manufacturers, and printers, ensuring that everyone is on the same page regarding the packaging’s design and structure.

What Should be Included in a Packaging Dieline?

- Product Dimensions: Start by specifying the dimensions of your packaging – length, width, and height. This information is critical for ensuring that the packaging fits the product snugly.

- Bleed and Trim Lines: Include bleed and trim lines to account for any design elements that extend beyond the final cut. Bleed ensures that the ink goes right to the edge of the printed material, while trim lines indicate where the packaging should be cut.

- Cut Lines and Perforations: Clearly mark where the packaging should be cut, folded, or perforated. This guides the manufacturer in the production process.

- Folding Instructions: If your packaging involves complex folds or assembly, provide clear folding instructions. This helps the assembly team understand how to put the packaging together correctly.

- Die Cut Indications: If your packaging requires die cutting (custom-shaped openings or designs), indicate these areas on the dieline. Die cut lines are essential for ensuring that the cutting process aligns with your design.

- Safety and Legal Information: Reserve space for essential legal and safety information, such as barcodes, nutritional labels, and warning labels. Ensure these elements are accurately placed within the dieline.

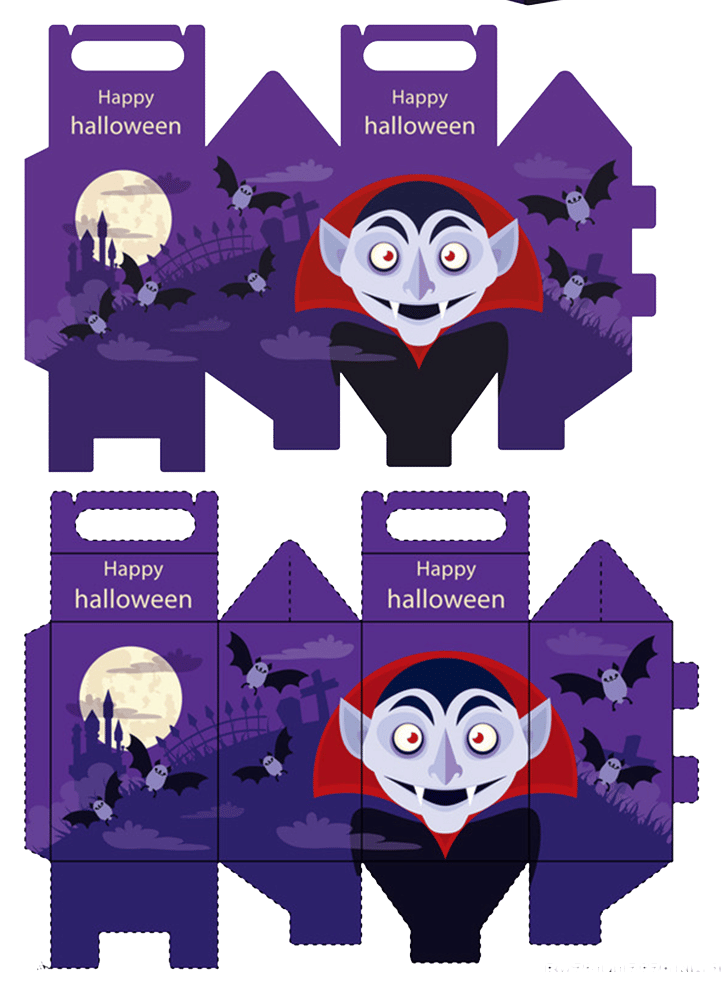

- Brand Elements: Include space for brand logos, taglines, and other brand-specific elements. Consistency in brand placement is crucial for brand recognition.

- Color Specifications: Specify color codes, ideally in Pantone or CMYK, to ensure color accuracy in printing. Include color swatches for reference.

- Font Styles and Sizes: Indicate the fonts, font sizes, and text placement within the dieline. This helps maintain consistency in typography.

- Finish and Coating Instructions: If your packaging requires specific finishes like gloss, matte, or special coatings, note these instructions on the dieline.

- Clear Zones: Designate areas where important information or design elements should not be placed to prevent interference with barcodes or legal text.

- Fold and Closure Types: If your packaging involves unique folding or closure mechanisms, provide detailed illustrations or descriptions to guide assembly.

Conclusion

A well-prepared packaging dieline is the cornerstone of a successful packaging design project. It ensures accuracy, cost-efficiency, and consistency throughout the production process. By including all the necessary elements, such as dimensions, cut lines, branding elements, and safety information, in your dieline, you pave the way for a visually appealing, functional, and on-brand packaging solution. Packaging dielines are the unsung heroes behind every attractive product on the retail shelf, and mastering their use is a crucial skill for any packaging designer.

If you are interested in custom packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Home » Packaging Dieline With Artwork: What Should Be Included?

Color plays a vital role in brand recognition, and it is especially important when it comes to packaging materials. The color of your packaging can

The journey of creating a compelling flexible packaging design starts with gaining insight into your target demographic. Thoroughly understand their needs, preferences, and factors that

In today’s market, the printing strategy employed on packaging can play a significant role in a product’s success. This guide is tailored to help buyers