Home » Optimizing Your Retail Displays: The Art of Material Selection

Optimizing Your Retail Displays: The Art of Material Selection

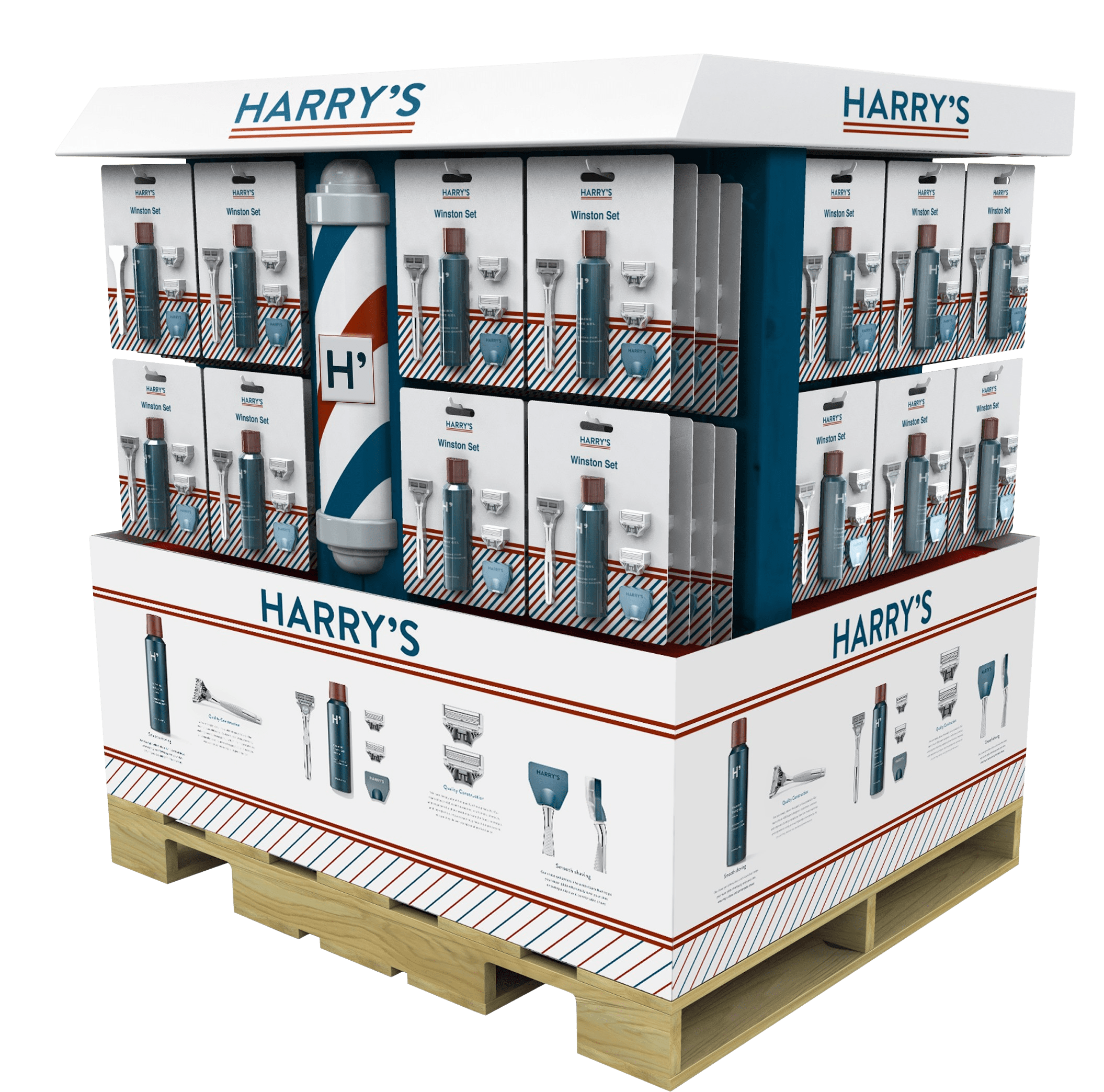

In the dynamic realm of retail, crafting the perfect display goes beyond just showcasing products – it’s about sparking customer interest, driving sales, and making a lasting impression. Key to this success is the strategic use of point-of-purchase (POP) displays, which have the power to influence buying decisions at the crucial moment. This guide delves into the essential factors to consider when choosing the right materials for your retail displays, ensuring that your creations stand out and make a genuine impact.

Balancing Cost and Quality

Your choice of materials significantly affects your display’s overall cost and quality. While cardboard offers an affordable option, plastic strikes a balance between cost and durability. Higher-end materials like wood and metal communicate luxury, potentially enhancing the perceived value of your products.

Ensuring Longevity and Durability

Consider the intended lifespan of your displays. Corrugated cardboard suits short-term promotions, while plastic, metal, and wood are better suited for long-lasting and semi-permanent installations. Plastic excels in semi-permanent setups, whereas wood and metal offer robustness for prolonged use.

Flexibility for In-Store Mobility

The ease of movement is vital for logistics and adaptability within the store. Well-designed displays simplify assembly, shipping, and rearrangement. Lightweight materials like cardboard are easy to transport and assemble, while plastic and metal provide flexibility in placement.

Safeguarding Products with Smart Design

Product protection is paramount, especially for fragile or valuable items. Metal, plastic, and wood offer enhanced impact resistance compared to cardboard. Secure display options like wire tethers can deter theft and prevent accidental damage.

Aesthetic Appeal and Brand Alignment

Materials contribute to the overall visual and tactile experience of your displays, playing a pivotal role in conveying your brand’s identity. Cardboard offers versatility in design, plastic exudes modernity, wood brings in natural charm, and metal adds a touch of sophistication. The inclusion of electronic components elevates interactivity and brand engagement.

Sustainability and Environmental Responsibility

In today’s eco-conscious landscape, consider the environmental impact of your display materials. Cardboard is a standout option due to its recyclability, while permanent materials generate less waste. Wood can often be repurposed, and metal is endlessly recyclable – align your choices with your brand’s commitment to sustainability.

Materials that Complement Product Vibes

Harmonize your display materials with your product type to create a coherent and captivating presentation. Cardboard’s adaptability suits a range of products, plastic shines for clothing and sleek items, wood adds warmth for food and wine displays, and metal lends an industrial edge for electronics and snacks.

If you are interested in point of purchase displays, then partner with Brown Packaging today.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Optimizing Your Retail Displays: The Art of Material Selection

Point-of-purchase (POP) displays must catch a shopper’s eye while also moving efficiently through the supply chain. Striking the right balance between visual impact and logistics

As retail environments evolve, Point of Purchase (POP) displays will continue to be an essential tool for capturing consumer attention and driving in-store sales. In

In the retail environment, the placement of Point of Purchase (POP) displays is just as critical as their design and content. Strategic positioning can significantly