Home » Optimizing Custom Packaging for International Shipping and Logistics

Optimizing Custom Packaging for International Shipping and Logistics

As international commerce continues to grow, optimizing custom packaging for international supply chains has become an essential aspect of any global business. In an increasingly connected world, businesses must ensure their goods are delivered to customers efficiently, safely, and in the most cost-effective manner. Here’s a detailed look into the importance of custom packaging and how to optimize it for international shipping and logistics.

Understanding Custom Packaging

Before delving into the intricacies of optimization, it’s essential to understand what custom packaging entails. Custom packaging is an all-encompassing term used to describe the bespoke packing materials designed specifically for a company’s product. This can include anything from branded boxes and tape to customized inserts and padding.

The goal of custom packaging is two-fold. First, it ensures the product arrives at its destination safely and in optimal condition. Second, it serves as an extension of the company’s brand, providing a unique unboxing experience that aligns with the brand’s values and aesthetics.

The Importance of Optimizing Custom Packaging for International Shipping

Optimizing custom packaging for international shipping has several benefits, including:

- Cost Efficiency: Properly optimized packaging can save your company significantly in shipping costs. By minimizing the weight and dimensions of your packages, you can reduce the shipping charges, which often depend on these factors.

- Reduced Damage Rates: Custom packaging that is optimized for international shipping can significantly reduce product damage during transit. This leads to fewer returns, refunds, or replacements and enhances your brand’s reputation.

- Improved Customer Satisfaction: A well-packaged product enhances the unboxing experience, leading to increased customer satisfaction. This can enhance customer loyalty and lead to repeat purchases.

Strategies for Optimizing Custom Packaging for International Shipping and Logistics

Evaluate Your Current Packaging

The first step towards optimizing your custom packaging is to evaluate your existing packaging. Consider aspects like size, weight, and the level of protection it offers your products. If your packaging is excessively large or heavy, it could be adding unnecessary costs to your shipping charges.

Choose the Right Packaging Material

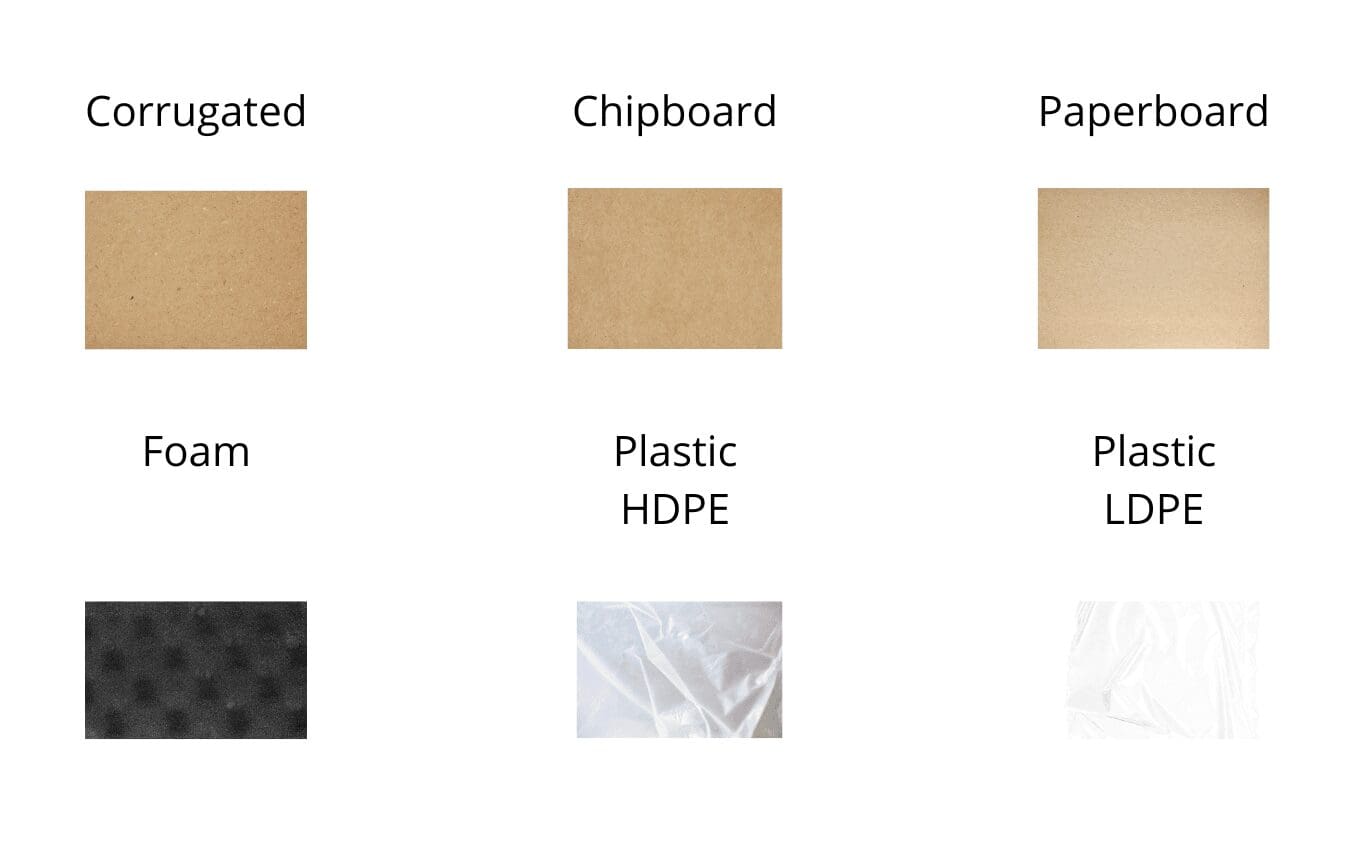

The choice of material plays a vital role in optimizing custom packaging. Consider materials that are lightweight, sturdy, and environmentally friendly. Depending on the nature of your products, materials like corrugated cardboard, Kraft paper, or biodegradable plastic can be good options.

Minimize Packaging Size and Weight

One of the primary ways to reduce shipping costs is to minimize the size and weight of your packaging. This does not mean compromising on the safety of your products. Instead, you should design your packaging in a way that it snugly fits your product, offering adequate protection without wasting space or material.

Use Protective Inserts

Protective inserts like bubble wrap, foam inserts, or inflatable air pillows can provide additional protection for your products, reducing the risk of damage during transit. These can be customized to fit your products perfectly, providing an optimal balance between protection and space utilization.

Standardize Your Packaging

Standardizing your packaging sizes can simplify your logistics and potentially lower costs. By having a few standard box sizes, you can streamline your packing process and reduce the need for custom-sized boxes for each product.

Consider Your Branding

While optimization is primarily about reducing costs and protecting products, branding is equally important. Your packaging is often the first physical interaction a customer has with your brand, so it should reflect your company’s identity. Use colors, logos, and designs that align with your brand aesthetic.

Work with Packaging Experts

Working with packaging experts can help you optimize your custom packaging effectively. These professionals can provide insights into the latest trends and technologies in packaging, as well as provide practical solutions tailored to your specific product and business needs.

Understand International Shipping Regulations

When shipping internationally, it’s essential to understand the various regulations and requirements set by different countries. Some countries have specific restrictions on packaging materials, while others have stringent labeling requirements. Working with a knowledgeable logistics partner can help ensure your packaging is compliant with all international regulations.

Leveraging Technology for Packaging Optimization

In the modern era, technology plays a significant role in optimizing custom packaging. Here are a few ways you can leverage technology:

Packaging Design Software

Packaging design software allows businesses to create custom designs for their packaging materials. With these tools, you can visualize how your package will look and make adjustments to optimize size, shape, and branding.

Automated Packaging Systems

Automated packaging systems can help optimize your packing process by reducing manual labor and increasing efficiency. These systems can assemble boxes, fill them with products and packing material, and then seal and label them, all in a streamlined, automated process.

Packaging Testing

Advanced packaging testing methods can assess the durability and efficiency of your packaging. These tests can simulate various environmental conditions and stresses that your packages might encounter during shipping, helping you to optimize your packaging for real-world conditions.

IoT and Smart Packaging

The Internet of Things (IoT) and smart packaging technologies can provide valuable insights into your shipping process. For instance, you can use sensors to track the conditions your packages experience during transit, helping you to make data-driven decisions to optimize your packaging.

If you are interested in optimizing your customizing packaging for international shipping and logistics, then partner with Brown Packaging today to get started.

Computer-Aided Packaging Engineering (CAPE)

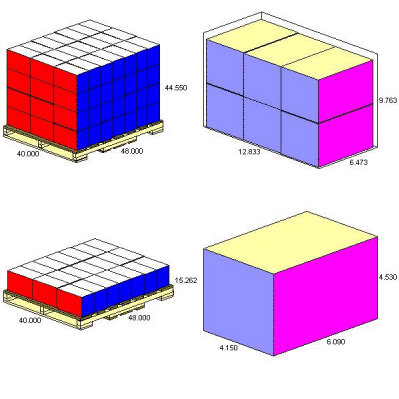

Computer-Aided Packaging Engineering (CAPE) stands as a pivotal technology in modern packaging optimization. Leveraging specialized software, CAPE allows businesses to virtually model, simulate, and evaluate packaging designs and logistics strategies. Its predictive modeling capabilities enable the identification of potential weaknesses and inefficiencies in packaging designs before physical production, saving resources.

CAPE facilitates material optimization, load arrangement within shipping containers, and assessment of environmental impact, helping to create sustainable and cost-effective packaging solutions. By integrating with IoT, real-time data on shipping conditions can enhance packaging design based on actual experiences. Collaborative design and compliance with international regulations are also streamlined through CAPE, offering businesses a competitive edge in the evolving global market.

If you are interested in optimizing your custom packaging for international supply chains, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Optimizing Custom Packaging for International Shipping and Logistics

In today’s fast-paced world, the logistics industry plays a crucial role in ensuring that products are delivered to customers in a timely and cost-effective manner.

In the diverse world of retail and e-commerce, managing multiple Stock Keeping Units (SKUs) can be a daunting task, especially when it comes to packaging.

Tariffs proposed for 2025 are set to reshape the packaging industry, driving changes in costs, sourcing, and lead times. For packaging buyers, one of the