Home » Meeting 2026 Packaging Compliance Standards

Meeting 2026 Packaging Compliance Standards

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships.

Why Compliance Matters in 2026

- Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications.

- E-commerce standards: Carriers enforce dimensional weight and package testing rules.

- Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines.

- Consumer trust: Transparency in packaging claims impacts purchasing decisions.

Key Compliance Areas for Buyers

- Material sourcing: FSC-certified corrugated and board for sustainability.

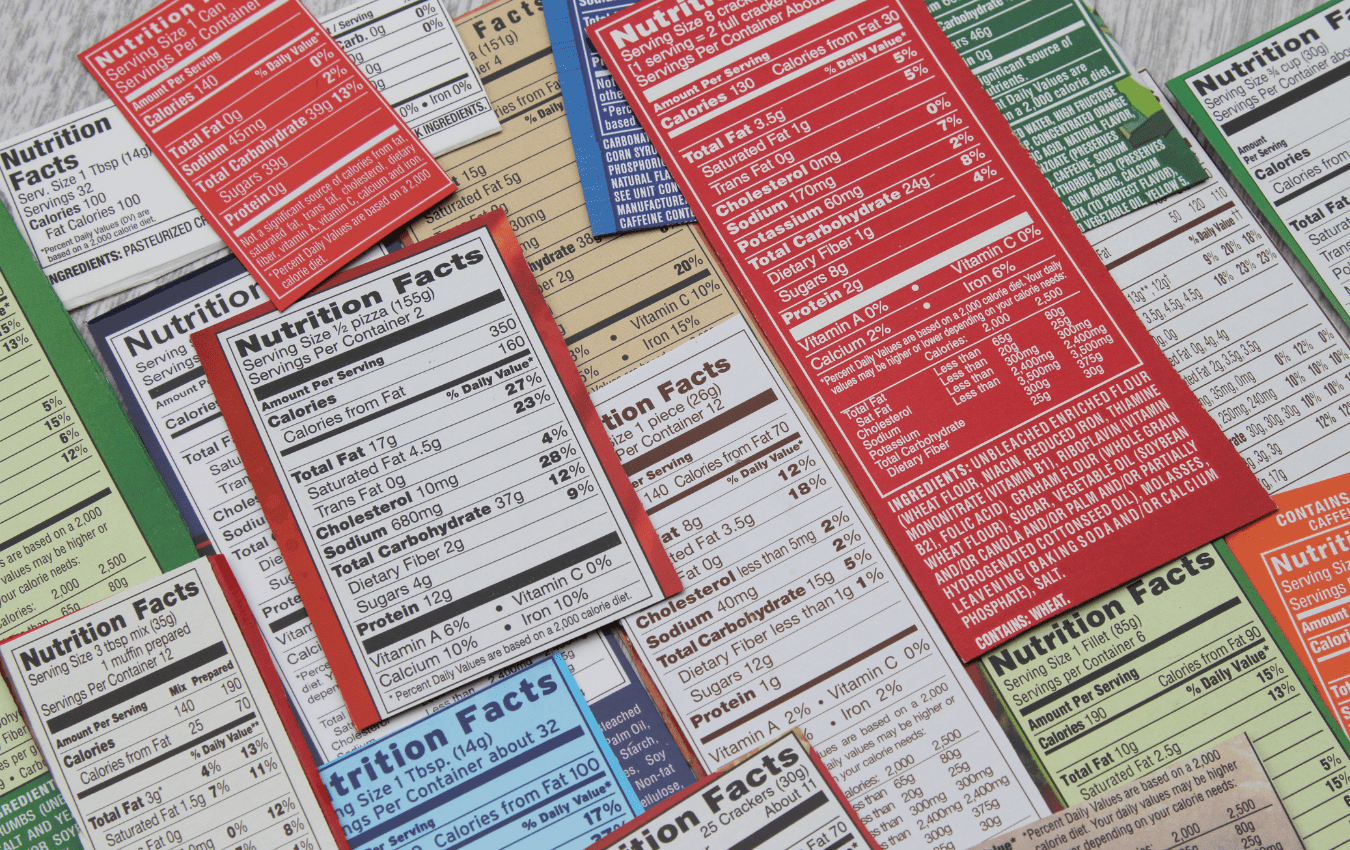

- Labeling standards: GS1-compliant barcodes and accurate product details.

- Durability testing: ISTA and ASTM protocols for drop, vibration, and compression.

- Sustainability regulations: Requirements for recyclable or compostable materials.

- Chemical restrictions: Compliance with FDA, EU, or state-specific standards.

Common Compliance Challenges

- Keeping up with frequent regulatory changes.

- Managing multiple certifications across suppliers.

- Balancing compliance with cost-efficiency.

- Verifying supplier claims for sustainability.

Best Practices for Staying Compliant

- Audit suppliers annually to confirm certification validity.

- Run internal packaging tests before scaling.

- Track regulatory updates for each region you ship to.

- Work with experienced partners who understand industry compliance.

Packaging Solutions with Brown Packaging

Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant.

References

Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.org

International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org

GS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Meeting 2026 Packaging Compliance Standards