Home » Is Your Packaging Costing You More Than It Should?

Is Your Packaging Costing You More Than It Should?

Packaging isn’t just a box or a bag—it’s a line item on your budget, a touchpoint with your customer, and a critical part of your supply chain. But what many companies don’t realize is that their packaging may be costing them more than it should—not just in materials, but in storage, shipping, damage, and customer experience.

If you haven’t taken a close look at your packaging setup lately, now’s the time to assess whether it’s helping or hurting your bottom line.

Oversized Packaging = Wasted Money

It’s a common mistake: using a box that’s much larger than the product. Not only does this require more void fill, it also increases your dimensional shipping weight, which drives up freight costs—especially for e-commerce and parcel shipping.

Solution:

Switch to right-sized packaging or explore mailer alternatives like poly mailers or custom die-cut corrugated options that hug the product more closely.

Over-Engineering Without Added Benefit

It’s easy to assume stronger means better—but not every product needs double-wall corrugated, high-end inserts, or expensive finishes. If your packaging is doing more than it needs to, you’re likely paying for protection or features your customer doesn’t notice or value.

Solution:

Review your structural design and board grade. A packaging engineer can help you optimize for the product’s weight and fragility without overspending on material.

Inefficient Packaging Leads to Higher Labor Costs

Packaging that’s hard to assemble, overcomplicated, or inconsistent can slow down fulfillment and increase errors.

Solution:

Use auto-lock bottom boxes, pre-folded cartons, or streamlined assembly instructions to reduce pack time, labor cost, and error rates.

Your Shipping and Fulfillment Costs Are Rising

Higher freight bills or warehouse inefficiencies are often tied to inefficient packaging: oversized boxes, time-consuming assembly, or mismatched pallets.

Why it matters:

This is the moment to reallocate budget toward structural redesign or automation-friendly packaging that reduces labor, materials, and dimensional weight.

Storage and Shipping Inefficiencies

If your packaging takes up too much warehouse space or doesn’t palletize efficiently, you’re losing money in storage and shipping before a product even leaves your facility.

Solution:

Work with your supplier to optimize dimensions for palletization and warehouse stacking. You may be able to reduce total storage volume or fit more units per shipment.

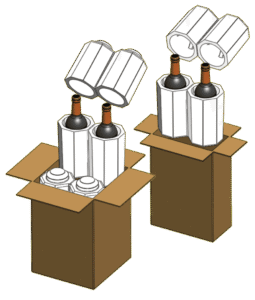

Damage and Returns Are Killing Margins

If your packaging fails in transit—even occasionally—the cost of returns, replacements, and negative reviews can quickly outweigh the cost of upgrading your packaging.

Solution:

If you’re seeing damage or breakage rates over 1–2%, it’s time to audit your box strength, inserts, and material choices. Improving packaging here is a direct path to better margins.

Missed Opportunities with Branding

Generic packaging may be cheaper—but it can cost you in brand recognition, customer loyalty, and perceived value. If your packaging doesn’t reflect your product quality, customers may assume it’s lower value.

Solution:

Consider affordable branding upgrades like one-color flexo print, interior printing, or custom labels to make a stronger impression without blowing the budget.

Final Thoughts

If you’re only looking at unit cost when reviewing packaging, you’re missing the bigger picture. True packaging costs include materials, shipping, labor, storage, damage, and brand perception.

Ready to find out if your packaging is costing more than it should?

We’ll help you audit your current setup and identify opportunities to save money—without compromising quality, protection, or your customer experience.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Home » Is Your Packaging Costing You More Than It Should?