Home » Is a Corrugated Box Good for Shipping?

Is a Corrugated Box Good for Shipping?

Yes, a corrugated box is an excellent choice for shipping due to its strong, durable nature and its ability to protect contents from damage during transit. Its structural integrity, coupled with its lightweight design, makes it ideal for a wide range of shipping needs, from delicate items to heavy goods.

Strength and Durability

The key to the corrugated box’s suitability for shipping lies in its unique construction. Composed of a fluted corrugated sheet sandwiched between two linerboards, this design creates a sturdy, yet cushioned, environment for items being shipped. The corrugation provides resistance against impacts, vibrations, and compression, significantly reducing the risk of damage. This structural strength is scalable; by adjusting the thickness of the board and the size of the flutes, corrugated boxes can be customized to handle various weight capacities and protection levels.

Versatility

Corrugated boxes offer unparalleled versatility. They can be customized in size, shape, and strength to suit specific shipping needs, whether for small, fragile items or large, bulky products. This customization extends to the printing and branding of the boxes, enabling businesses to use their packaging as a marketing tool. Moreover, additional features like handles, die-cut inserts, or reinforced corners can be added to enhance functionality and protection.

Sustainability

In an era where environmental concerns are increasingly important, corrugated boxes stand out for their eco-friendliness. Made from renewable resources, primarily recycled paper, corrugated boxes are recyclable and biodegradable. Their production and recycling processes are energy efficient and contribute to a reduction in carbon footprint, making corrugated boxes a responsible choice for businesses committed to sustainability.

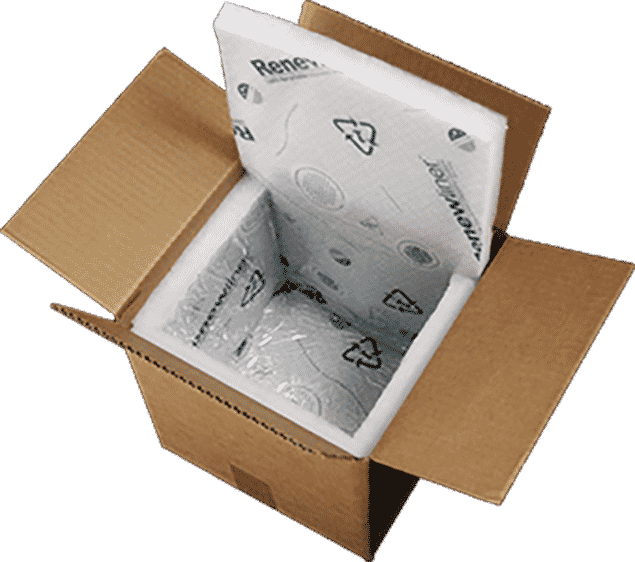

Protective Features

Corrugated boxes can also be equipped with various protective features to enhance their shipping capabilities. These include water-resistant coatings or liners, which protect against moisture and humidity, and barrier coatings that guard against oil, grease, or other contaminants. For items requiring temperature control, insulated corrugated boxes are available to maintain a stable environment during transit.

Ease of Use

The simplicity and ease of use of corrugated boxes are significant benefits. They can be quickly assembled, filled, sealed, and labeled, making the packing process efficient and straightforward. At the destination, they are easy to open and, if undamaged, can be reused or recycled, contributing to waste reduction.

Conclusion

Corrugated boxes are indeed an excellent choice for shipping, offering a combination of strength, durability, cost efficiency, and environmental sustainability. Their adaptability to various shipping requirements, coupled with protective and customizable features, makes them a reliable packaging solution for businesses and individuals worldwide. Whether you’re shipping locally or internationally, corrugated boxes ensure that your products arrive safely, securely, and in style.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Is a Corrugated Box Good for Shipping?