Home » Insulated Packaging Explained: What You Should Know

Insulated Packaging Explained: What You Should Know

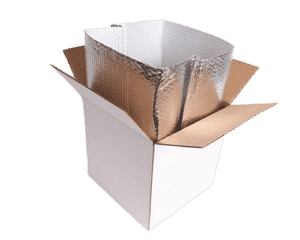

In a world where a wide range of products require special handling to maintain their quality, insulated packaging has emerged as a crucial solution for protecting temperature-sensitive items from both UV radiation and temperature fluctuations. Whether it’s perishable food items, pharmaceuticals, or sensitive electronics, maintaining the right temperature during storage and transportation is paramount. In this blog, we’ll explore insulated packaging, its functions, features, benefits, and applications in safeguarding temperature-sensitive products.

Understanding Insulated Packaging

Insulated packaging, also known as thermal packaging or temperature-controlled packaging, is designed to create a controlled environment within the package. It acts as a protective shield against external factors, including temperature fluctuations and UV radiation, to maintain the integrity and quality of the enclosed products.

Functions and Features

- Temperature Stability:

The primary function of insulated packaging is to maintain a stable temperature environment inside the package. It accomplishes this through the use of insulating materials that resist heat transfer, keeping the contents at the desired temperature.

- UV Radiation Blockage:

Insulated packaging often includes materials that provide protection against UV radiation. These materials block harmful UV rays, preventing them from reaching and potentially damaging the enclosed products.

- Insulation Materials:

Insulated packaging employs a variety of insulation materials such as foam, reflective films, and vacuum insulation panels. These materials help regulate temperature and prevent heat or cold from penetrating the package.

- Temperature Monitoring:

Some insulated packaging solutions come equipped with temperature monitoring devices like data loggers or indicators. These devices allow for real-time monitoring of the internal temperature, ensuring that it remains within the desired range.

Benefits of Insulated Packaging

- Product Quality Preservation:

Insulated packaging ensures that temperature-sensitive products, including food, medications, and electronics, maintain their quality and efficacy throughout their journey from manufacturer to end-user.

- Extended Shelf Life:

Products with shorter shelf lives can benefit from insulated packaging. It helps extend the time during which these products remain safe and viable for consumption or use.

- Reduced Waste:

By preventing spoilage and product degradation, insulated packaging reduces the amount of wasted products, saving both resources and money.

- Enhanced Brand Reputation:

Companies that prioritize the protection of temperature-sensitive products through insulated packaging can build trust with consumers and enhance their brand reputation.

Applications of Insulated Packaging

Insulated packaging finds application in various industries:

- Food and Beverage:

Insulated packaging is widely used for shipping perishable food items, including fresh produce, dairy products, and frozen goods. It ensures that these products reach consumers in optimal condition.

- Pharmaceuticals:

Pharmaceutical companies rely on insulated packaging to transport temperature-sensitive medications and vaccines, ensuring their safety and efficacy.

- Electronics:

Sensitive electronic components and devices, such as microchips and batteries, benefit from insulated packaging to prevent damage caused by temperature fluctuations.

- Online Retail:

E-commerce companies often use insulated packaging for shipping products that require temperature control, such as meal kits and specialty cosmetics.

If you are interested in insulated packaging, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Insulated Packaging Explained: What You Should Know

In a world where a wide range of products require special handling to maintain their quality, insulated packaging has emerged as a crucial solution for

The cold chain is a temperature-controlled supply chain that plays a critical role in ensuring that certain products, such as pharmaceuticals, vaccines, and food, maintain

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right