Home » Innovative Custom Packaging Ideas for Limited Edition and Special Collections

Innovative Custom Packaging Ideas for Limited Edition and Special Collections

Limited edition and special collection items provide a unique customer experience that can significantly elevate a brand’s appeal. One way to make these products stand out is through innovative custom packaging. It’s an important aspect that, when executed thoughtfully, can transform an ordinary item into an unforgettable, must-have product. This article explores a series of innovative custom packaging ideas that will make your limited edition or special collection products genuinely special.

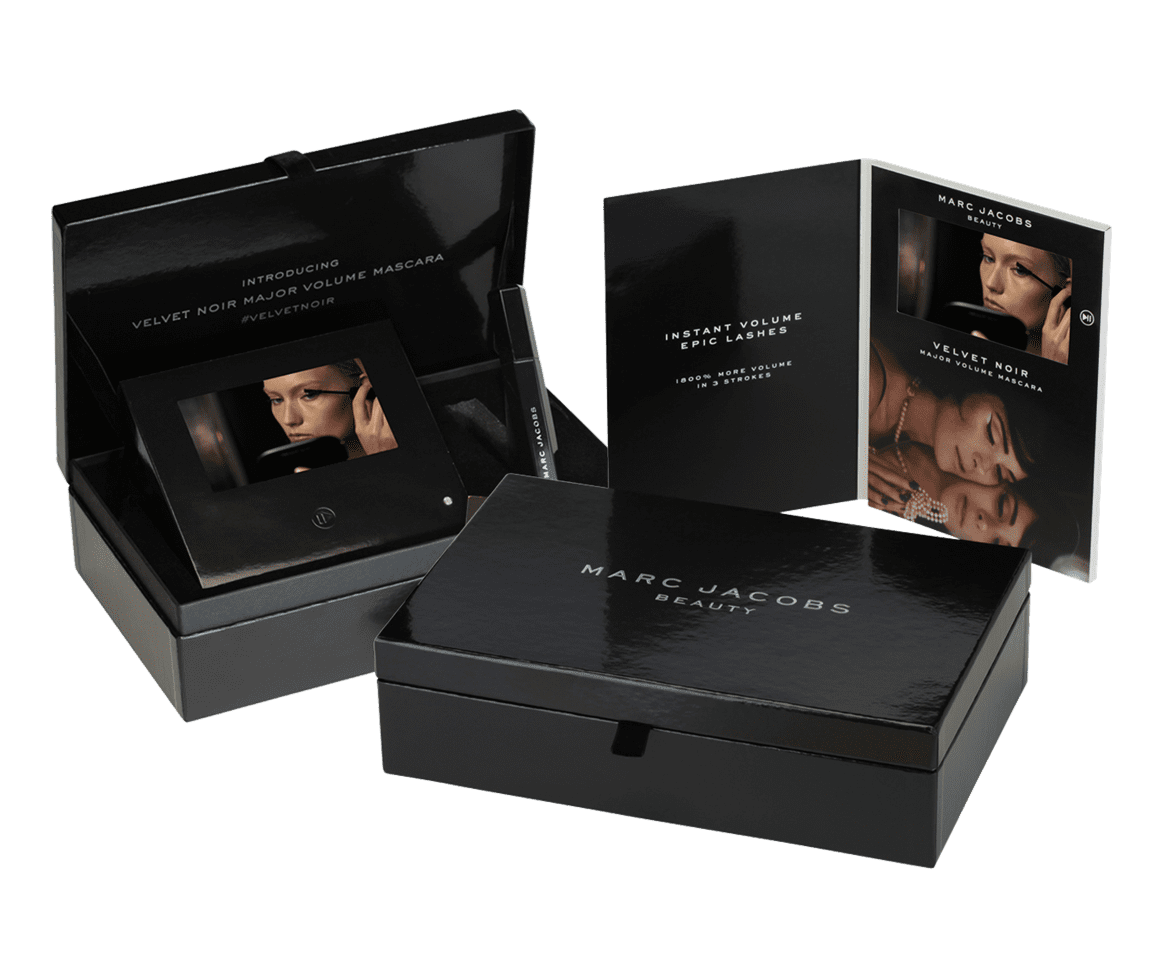

Creative Unboxing Experiences

The unboxing experience is an exciting moment for customers. It’s a chance for brands to impress and surprise, heightening the sense of exclusivity. Consider designing a package that unfolds, slides open, or otherwise transforms during unboxing. You could also include unique, reusable packaging materials, such as branded tissue paper or decorative ribbons.

Sustainability-Focused Packaging

With consumers increasingly concerned about the environment, sustainable packaging is more than just a trend; it’s an expectation. Consider using biodegradable or recyclable materials for your packaging. Additionally, reusable packaging that serves a secondary purpose, like storage containers or tote bags, can add an extra level of appeal. Packaging made from plantable seed paper, for example, can transform into a beautiful array of flowers, herbs, or vegetables.

Handcrafted Wooden Boxes

Wooden boxes add a premium feel to any product, and they can be especially effective for limited edition items. They can be custom carved, painted, or engraved to match the product or the brand’s aesthetic. Plus, they’re reusable and often kept by customers as keepsakes.

Augmented Reality Packaging

Technology has opened up exciting new opportunities for custom packaging. Augmented reality (AR) is one such innovation that brands can leverage. With an AR app, customers can point their smartphones at the packaging to bring up additional content, such as videos, 3D models, or interactive experiences. This feature can make the unboxing experience feel even more exclusive and personalized.

Custom Illustrations and Artwork

Another way to create an exclusive feeling with your packaging is to incorporate custom illustrations or artwork. You could commission a local artist or run a competition among your customers for the design. This not only makes the package unique; it also creates a stronger connection with the community around your brand.

Hidden Messages or Surprises

Including hidden messages or surprises in your packaging can create a memorable unboxing experience. This could be anything from a hidden compartment with a bonus item, a message printed on the inside of the box, or a puzzle or game incorporated into the package design.

Personalized Packaging

Personalization can take various forms, from printing the customer’s name on the box to including custom items based on their preferences. This requires more effort on the brand’s part, but the increased customer satisfaction and word-of-mouth marketing can make it worthwhile.

Limited Edition Labels or Badges

Include unique labels or badges on your packaging to highlight the exclusivity of limited edition products. This could be a serialized label indicating which number of the product the customer has received (e.g., “No. 1 of 500”) or a unique badge that isn’t included with the standard edition of the product.

Storytelling Through Packaging

Incorporate elements of storytelling into your packaging. This could be the story of how the product was made, the inspiration behind the collection, or information about the people who made it. This not only makes the packaging more interesting; it also helps create a deeper connection between the customer and the product.

Thematic Packaging

Finally, consider thematic packaging that ties into the specific collection or season. This could involve specific colors, designs, or materials related to the theme. For instance, a winter collection might use snowy motifs, metallic accents, and cool-toned colors, while a spring collection could incorporate floral patterns, pastel colors, and sustainable materials. Similarly, a limited-edition product released in conjunction with a special event, like a movie premiere or a sports championship, could feature design elements related to that event.

If you are interested in custom packaging, then partner with Brown Packaging today.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Innovative Custom Packaging Ideas for Limited Edition and Special Collections

The holiday season pushes packaging supply chains to their limits. With surging e-commerce demand, constrained carrier capacity, and rising material costs, packaging buyers must navigate

In the world of product manufacturing and retail, packaging plays a crucial role in protecting products, attracting consumers, and conveying brand messages. Among the various

Selecting the right packaging materials is a critical decision for businesses, impacting everything from product protection and shelf life to brand perception and sustainability. With