Home » How to Stack Corrugated Bin Boxes: A Step-by-Step Guide

How to Stack Corrugated Bin Boxes: A Step-by-Step Guide

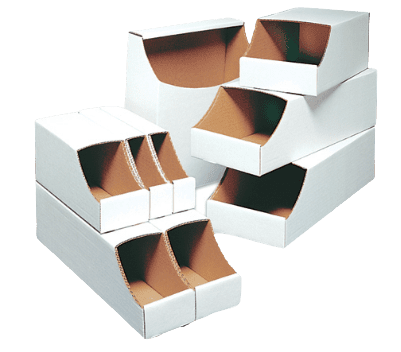

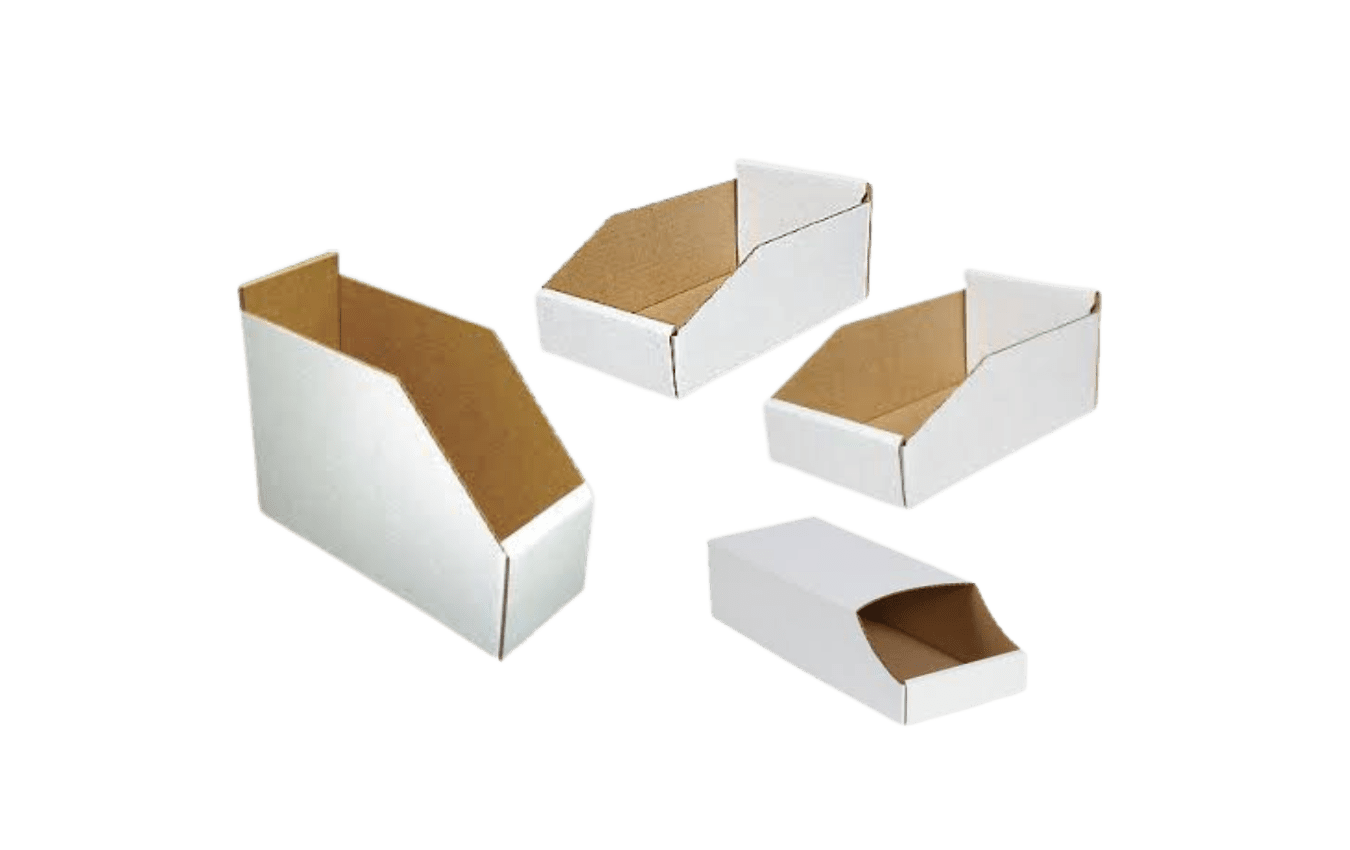

Corrugated bin boxes are widely used for storage and organization, especially in warehouses and retail settings. When used and stacked properly, they offer an efficient way to store small items, parts, or products. However, if you’re not careful, stacking them haphazardly can lead to instability and potential damage to both the boxes and their contents. Here’s a step-by-step guide to stack corrugated bin boxes safely and efficiently.

Step 1. Start with a Strong Foundation

Before you begin stacking, ensure you have a firm and level surface. This could be a sturdy table, a shelving unit, or a flat area of the floor. A good foundation ensures the boxes will not tip over or collapse under the weight.

Step 2. Inspect Your Boxes

Examine each box for signs of wear, tear, or damage. A damaged box might not have the structural integrity to hold weight or stay upright, especially when stacked.

Step 3. Choose the Right Size

Start with the largest and sturdiest boxes at the bottom. As you build up, the boxes should become progressively smaller. This creates a pyramid-like structure, ensuring stability.

Step 4. Mind the Weight

Be mindful of the weight you’re putting into each box. A heavier box placed on top of a lighter box can lead to a collapse. Best rule of thumb, is placing the heavier boxes on bottom with the lighter boxes on top.

Step 5. Align the Edges

When stacking, make sure the edges of the boxes line up as precisely as possible. This ensures that the weight is distributed evenly across the surface of the box below and reduces the risk of tipping.

Step 6. Avoid Overloading

It’s essential to avoid overstuffing the boxes. An overstuffed box can bulge, making it uneven and unstable when stacked. It can also lead to the contents spilling out or the box tearing.

Step 7. Leave Some Space

If you’re stacking boxes on a shelf, make sure there’s a little space between the top of the highest box and the shelf above. This not only makes it easier to retrieve boxes but also ensures that there’s adequate airflow, reducing the risk of moisture buildup, which can weaken corrugated boxes.

Step 8. Label Clearly

Label each box clearly on the front and sides, so you can quickly identify its contents without having to unstack or move multiple boxes.

Step9. Regularly Check for Stability

Every so often, give your stack of boxes a gentle push to ensure they’re still stable. Over time, the weight distribution inside boxes might change, or the boxes themselves could wear down, impacting their stability.

Step 10. Replace Worn Out Boxes

If a box shows signs of wear or begins to sag, replace it. Regularly rotating out old or worn boxes ensures the entire stack remains stable and that your items are safe.

Step 11. Use Dividers if Needed

If you’re storing many small items in one box, use dividers. These can prevent items from shifting too much, which can lead to an uneven distribution of weight.

Final Thoughts

Corrugated bin boxes are a versatile and eco-friendly solution for storage needs. By following these stacking guidelines, you can ensure the safety and longevity of both your boxes and their contents. Always prioritize stability and avoid the temptation to stack too high – it’s better to have two stable shorter stacks than one towering, unstable one. Safe stacking!

If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started.

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » How to Stack Corrugated Bin Boxes: A Step-by-Step Guide

When choosing corrugated packaging, box style directly impacts cost, strength, speed of packing, and customer experience. Two of the most common options are the Regular

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it

In the dynamic world of packaging, two materials often stand at the forefront: traditional corrugated cardboard and its modern counterpart, plastic corrugated. While both have