Home » How to Reduce Waste with Flexible Packaging: A Comprehensive Guide

How to Reduce Waste with Flexible Packaging: A Comprehensive Guide

It’s no secret that we’re living in an era characterized by the urgent need for environmental sustainability. With escalating concerns about the waste generated by traditional packaging, it’s essential that businesses and consumers alike pay keen attention to the kind of packaging they use. One practical solution emerging as a frontrunner is flexible packaging.

This blog post will delve into the innovative world of flexible packaging and illustrate how it can contribute significantly to waste reduction. It’ll also explore the potential of flexible packaging to lead the packaging industry toward sustainability.

Understanding Flexible Packaging

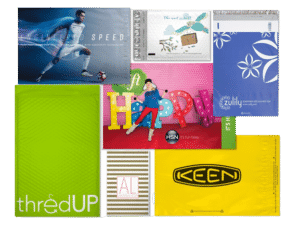

Before we dive into the specifics of waste reduction, let’s first understand what flexible packaging entails. At its core, flexible packaging refers to any packaging type that can easily change shape when filled with a product or after the product is removed. These include pouches, bags, films, and envelopes. Flexible packaging materials are often lightweight, which reduces shipping weight, and can be manufactured using fewer materials, which can reduce resource consumption.

How Flexible Packaging Reduces Waste

Flexible packaging, by its very nature, offers multiple avenues through which waste can be reduced. Here are a few:

Efficient Use of Materials

Unlike rigid packaging, flexible packaging uses significantly fewer materials. By using less, we naturally produce less waste. Flexible packaging often involves thinner and lighter materials, which also require less energy for production and transport, contributing to lower carbon emissions.

Product Protection and Preservation

Flexible packaging offers excellent product protection, reducing the chances of product damage during transit. It also provides superior barriers against moisture, light, and oxygen, which enhances product shelf life. By reducing spoilage and product damage, flexible packaging reduces waste associated with unsold or unusable goods.

Optimized Logistics

The lightweight and compact nature of flexible packaging means more products can be transported in one go. This efficiency reduces the number of trips needed, thus reducing fuel consumption and carbon emissions.

Best Practices for Implementing Flexible Packaging

Knowing that flexible packaging can reduce waste is one thing, but successfully implementing it in your business is another. Here are a few tips:

Understand Your Packaging Needs

First, identify your specific packaging needs. Consider the nature of your product, its shelf life, and how it’s typically transported. These factors will help you choose the most appropriate type of flexible packaging.

Work With a Reputable Manufacturer

Ensure you’re working with a reputable flexible packaging manufacturer who values sustainability. They should be able to provide you with the best materials for your needs and offer advice on how to maximize waste reduction.

Educate Your Consumers

Make sure your consumers understand the value of flexible packaging. Educate them on how to properly dispose of the packaging or, if possible, reuse it.

The Future of Flexible Packaging

The benefits of flexible packaging extend beyond waste reduction. With continued technological advancements, the industry is working towards even more sustainable options. Innovations like compostable and biodegradable flexible packaging are paving the way for a future where packaging can be both convenient and kind to the planet.

If you are interested in flexible packaging, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » How to Reduce Waste with Flexible Packaging: A Comprehensive Guide

Protein bars are a popular on-the-go snack, requiring durable, protective, and visually appealing packaging to ensure freshness and convenience. The right packaging helps extend shelf

When it comes to shipping or storing fragile items, ensuring their safe arrival without any damage is of utmost importance. Fragile items such as glassware,

For businesses, the decision to change packaging suppliers can be driven by various factors such as cost, quality, service, or the need for innovation. However,