Home » How to Optimize Your Packaging in Delivery Trucks Using CAPE Software

How to Optimize Your Packaging in Delivery Trucks Using CAPE Software

In today’s fast-paced world, the logistics industry plays a crucial role in ensuring that products are delivered to customers in a timely and cost-effective manner. One of the primary challenges faced by logistics companies is optimizing delivery trucks to carry as many products as possible while minimizing transportation costs. The use of pallets filled with packaging products is a popular method of optimizing delivery trucks, and with the help of CAPE (Computer-Aided Packaging Engineering) software, this process can be even more effective and efficient.

What are Pallets?

Pallets are flat structures made of wood, plastic, or metal that are used to transport goods. They provide a stable base for the goods being transported, reducing the risk of damage during transportation. Pallets come in different sizes, but the most common size is 48×40 inches.

Packaging Products

Packaging products are materials used to protect and secure goods during transportation, such as corrugated boxes, stretch film, corner protectors, and cushioning materials like bubble wrap. They come in different sizes and shapes to fit different types of goods.

Optimizing Delivery Trucks with Pallets Filled with Packaging Products Using CAPE Software

CAPE software is a valuable tool for optimizing the use of pallets filled with packaging products in delivery trucks. It enables logistics companies to streamline their packaging processes and maximize the efficiency of their truck loading operations. Here’s how to optimize your packaging in delivery trucks using CAPE software:

Step 1: Choose the Right Pallets

With CAPE software, you can input the dimensions and weight of your goods, and it will help you determine the appropriate pallet size and type. The software takes into account factors such as load-bearing capacity and compatibility with handling equipment. It ensures that you choose the right pallets to safely and efficiently transport your goods.

Step 2: Choose the Right Packaging Products

CAPE software allows you to simulate different packaging scenarios and assess the impact on space utilization and product protection. It helps you select the most suitable packaging products for your goods, considering factors such as fragility, weight, and size. By using the software, you can make informed decisions about the types and quantities of packaging products required to secure your goods effectively.

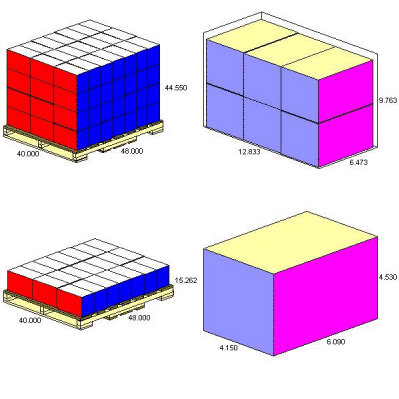

Step 3: Pack the Goods Efficiently

CAPE software provides virtual packing simulations, allowing you to visualize how your goods will fit onto the pallets. It helps you optimize the arrangement of products, ensuring efficient use of space and minimizing the risk of damage during transportation. The software considers the shape, dimensions, and weight distribution of the goods, helping you pack them in the most space-efficient and secure manner.

Step 4: Load the Pallets onto the Delivery Truck

CAPE software assists in determining the most efficient loading sequence for pallets onto the delivery truck. It takes into account factors such as weight distribution, stability, and accessibility. By following the loading instructions provided by the software, you can ensure that the pallets are loaded safely and securely, maximizing the use of available space within the truck.

Step 5: Optimize Routing and Consolidation

CAPE software can also assist in optimizing routing and consolidation strategies. By considering factors such as delivery destinations, weight distribution, and delivery schedules, the software helps logistics companies make informed decisions about the most efficient routes and consolidation options. This reduces the number of trips required and maximizes the utilization of delivery trucks, resulting in cost savings and reduced carbon footprint.

By incorporating CAPE software into your packaging optimization process, you can enhance the efficiency, accuracy, and sustainability of your delivery truck operations. The software enables you to make data-driven decisions, leading to improved space utilization, reduced transportation costs, and minimized environmental impact.

Leveraging Expertise for Successful CAPE Software Implementation

Implementing CAPE software requires expertise and support, so consult with professionals experienced in CAPE software implementation. These experts can provide guidance on utilizing the software effectively and optimizing your packaging in delivery trucks.

Additionally, consider partnering with packaging solution providers who have expertise in optimizing delivery truck logistics. They can offer insights on best practices, recommend suitable packaging materials, and assist in the implementation of CAPE software.

Through their expertise, they can help you:

- Analyze and Evaluate: Experienced professionals can assess your current packaging and delivery processes, identifying areas for improvement. They can analyze factors such as product dimensions, weight, fragility, and transportation requirements to determine the optimal packaging solution.

- CAPE Software Integration: Professionals skilled in CAPE software can guide you through its integration into your packaging optimization workflow. They will assist in data input, simulations, and analysis to achieve the best results in terms of space utilization, load stability, and product protection.

- Packaging Material Selection: Partnering with packaging experts ensures that you choose the right materials for your specific goods. They can recommend packaging products such as corrugated boxes, stretch film, corner protectors, and cushioning materials that align with your requirements and maximize protection during transportation.

- Efficient Packing Strategies: Professionals can provide insights and strategies for efficient packing, considering factors like weight distribution, stacking arrangements, and load stability. This ensures that you maximize the available space on pallets and minimize the risk of damage during transit.

- Continuous Improvement: Collaboration with experts in packaging optimization and CAPE software allows for ongoing evaluation and improvement. They can help you analyze data, identify areas for further optimization, and refine your packaging processes over time.

If you are interested in optimizing your packaging in delivery trucks with CAPE, then partner with Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » How to Optimize Your Packaging in Delivery Trucks Using CAPE Software

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of

In the realm of packaging solutions, roll end tuck top (RETT) boxes are hailed for their durability and versatile design. Yet, among their many attributes,

When it comes to delivering the beloved and delicious treat that is pizza, the packaging plays a crucial role. The right pizza box not only