Home » How to Design E-Commerce Packaging for Easy Returns

How to Design E-Commerce Packaging for Easy Returns

In e-commerce, the customer experience doesn’t end with the sale—it often continues through the returns process. With many customers expecting hassle-free returns, especially during the holiday season, businesses must design their packaging to simplify this step. Not only does this improve customer satisfaction, but it can also increase the likelihood of repeat purchases. Below is a guide to help you design e-commerce packaging that makes returns as seamless as possible.

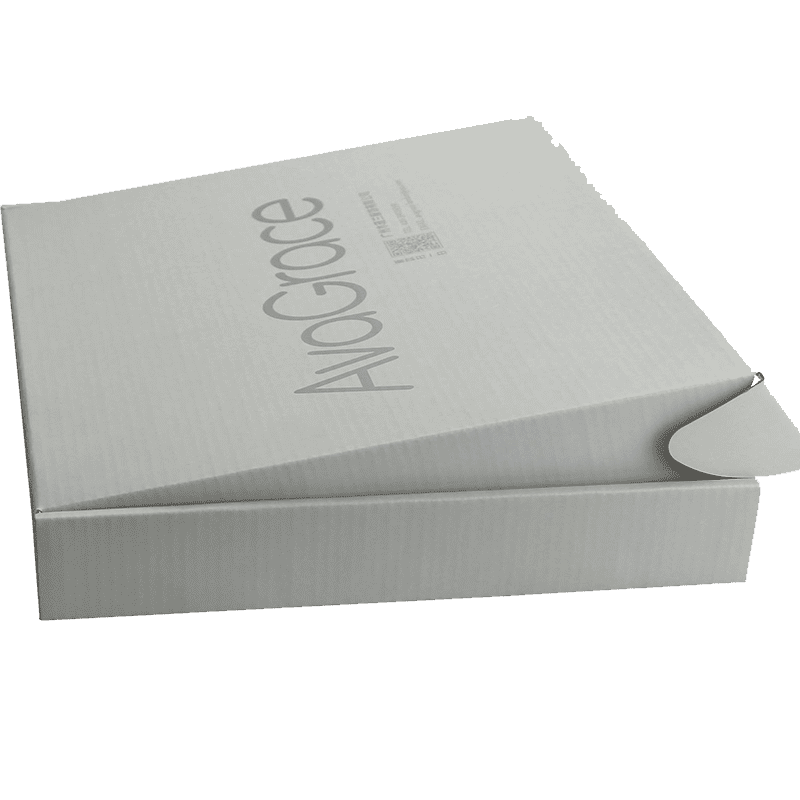

Use Reusable Packaging for Returns

One of the most important factors in return-friendly packaging is ensuring the package can be reused for returns. Instead of expecting customers to find new boxes or envelopes, design your packaging to serve dual purposes—both for outbound shipping and return shipping.

How to Design Reusable Packaging:

- Tear-Open Strips: Incorporate tear-open strips that allow customers to open the package without damaging it. This keeps the original packaging intact and ready to be reused for the return process.

- Double-Seal Adhesive Strips: Include a second adhesive strip inside the box or mailer. This allows customers to reseal the package securely when returning the item.

- Durability for Multiple Uses: Ensure the packaging is durable enough to handle multiple shipments. Reinforced materials or boxes with extra strength will prevent damage during return shipping.

By designing reusable packaging, you not only make it easier for customers to return items but also minimize the environmental impact by reducing packaging waste.

Provide Clear Return Instructions Inside the Packaging

A major pain point for customers returning items is not understanding the return process. Eliminate confusion by providing clear, concise instructions inside the packaging. These instructions should be simple and easy to follow, guiding the customer through every step of the return.

Tips for Clear Return Instructions:

- Step-by-Step Guide: Include a step-by-step guide on how to repackage the item and ship it back. Make sure to mention whether customers need to attach any return labels, or if it’s already included.

- Visuals: Adding images or illustrations can make the process easier to understand, especially for customers who may be unfamiliar with the return process.

- Dedicated Customer Service Contact: Provide a direct phone number, email, or live chat option for customers who need help with returns. Clear communication can ease frustration and build trust in your brand.

Include Prepaid Return Labels

A prepaid return label takes the hassle out of the return process for the customer. If you can, provide a prepaid shipping label within the package. This convenience encourages customers to make returns quickly and easily without having to navigate the post office or pay for shipping costs.

Benefits of Prepaid Return Labels:

- Simplifies the Process: Customers can just peel off the return label and stick it on the box, making the process almost effortless.

- Boosts Customer Loyalty: Free or prepaid returns show that you value your customers’ time and experience, leading to increased loyalty and repeat purchases.

- Faster Returns: By streamlining the process, prepaid return labels encourage faster returns, helping you get items back in stock quickly.

If offering prepaid returns is too costly for your business, consider offering discounted return labels or partnering with a shipping service that offers reduced rates.

Design for Minimal Repackaging

Some customers find repackaging to be one of the most frustrating parts of the return process. To minimize this pain point, design packaging that requires minimal effort to repack. When a customer can easily slide an item back into the original box or pouch without the need for excess tape or bubble wrap, the returns process becomes less daunting.

Key Design Features for Minimal Repackaging:

- Fitted Inserts: Use fitted foam or cardboard inserts that hold the product securely but are easy to remove and replace.

- Simple Closures: Avoid packaging designs that require too many steps to reassemble, such as intricate folding or complex locks.

- Clear Layout: When customers receive the package, they should be able to easily understand how to return the item to its original place.

By focusing on user-friendly designs, you simplify the experience for customers and reduce frustration during returns.

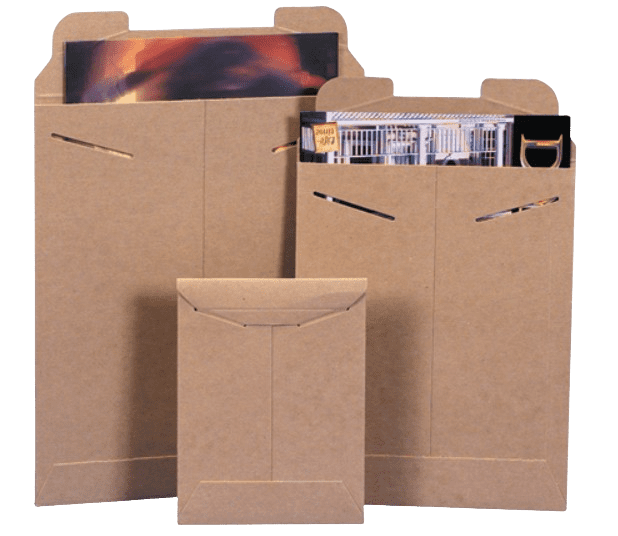

Ensure the Packaging is Return-Label Friendly

Make sure your packaging has a designated area for return labels. Often, customers need to affix a return label on top of the existing shipping label, which can lead to confusion if there’s no clear place to do so. Designing packaging with a specific area for return labels, whether it’s a flat section on a box or an easily accessible area on a mailer, streamlines the process.

Tips for Return-Label-Friendly Packaging:

- Smooth Surface: Ensure there is a smooth, flat surface for labels to be easily applied and visible for shipping carriers.

- Removable Shipping Labels: Consider designing packaging with removable shipping labels that can be peeled off or replaced with return labels. This reduces any risk of confusion during return shipping.

Make Sustainability a Priority

Customers today are more eco-conscious than ever. By offering sustainable packaging that can be reused for returns, your brand shows its commitment to the environment. Not only does this reflect positively on your business, but it also reduces waste associated with returns.

Sustainable Return Packaging Ideas:

- Recyclable and Compostable Materials: Use recyclable or compostable materials in your packaging design to ensure that even after returns, the packaging can be disposed of responsibly.

- Reusable Bags or Pouches: For apparel and accessories, consider using reusable bags that customers can send back with ease. These not only enhance sustainability but can also provide additional branding opportunities.

Branding During the Returns Process

The returns process is another opportunity to leave a lasting impression on your customers. Even though the customer is returning a product, branded packaging and thoughtful messaging can reinforce your commitment to customer satisfaction and encourage them to shop with you again in the future.

How to Leverage Branding During Returns:

- Thank-You Notes: Include a small thank-you note or a message that acknowledges the return but invites the customer to try again with a new product.

- Loyalty Promotions: Offering a discount code or loyalty points for a future purchase can turn the return into a positive experience, motivating customers to come back and shop with you again.

By incorporating branding into the returns experience, you can transform a potentially negative interaction into a positive one that strengthens your relationship with the customer.

Conclusion

Designing your e-commerce packaging for easy returns is essential to providing a seamless customer experience. By using reusable packaging, including prepaid return labels, providing clear instructions, and offering sustainable options, you can enhance customer satisfaction and build long-term loyalty. With the right return-friendly packaging design, your e-commerce brand can stand out and offer a truly customer-focused experience that encourages repeat business.

If you’re interested in ecommerce packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » How to Design E-Commerce Packaging for Easy Returns