Home » How To Conduct a Cost Analysis on Your Packaging

How To Conduct a Cost Analysis on Your Packaging

In today’s competitive market, understanding and optimizing the cost of your packaging is crucial for maintaining profitability and enhancing overall business performance. A thorough cost analysis of your packaging can reveal opportunities for cost savings and efficiency improvements. This blog post provides a detailed guide on how to conduct a cost analysis on your packaging.

Understanding the Importance of Packaging Cost Analysis

Before diving into the analysis, it’s essential to understand why it matters. Packaging costs can significantly impact your product’s price and your company’s bottom line. An effective cost analysis helps in identifying areas where expenses can be reduced without compromising quality or customer satisfaction.

Step 1: Identify All Packaging Components

Start by listing all elements that make up your packaging, including:

- Primary Packaging: The immediate packaging that holds your product.

- Secondary Packaging: Additional layers like boxes or wrappers for protection and branding.

- Tertiary Packaging: Bulk packaging used for transportation and storage.

- Labeling and Graphics: Costs associated with branding, labeling, and graphic design.

Step 2: Calculate Material Costs

Assess the cost of materials used for each packaging component. Consider:

- Unit Costs: Calculate the cost per unit of each material used.

- Bulk Discounts: Factor in discounts for bulk purchases, if applicable.

- Sustainable Materials: Compare costs of traditional materials with sustainable alternatives.

Step 3: Include Design and Development Costs

This includes:

- Design Fees: Costs paid to designers for packaging design.

- Prototyping Costs: Expenses for creating sample packaging for testing.

- Testing and Compliance: Costs associated with ensuring packaging meets industry standards.

Step 4: Factor in Storage and Handling Costs

These are often overlooked but crucial:

- Warehouse Storage: Costs for storing packaging materials.

- Handling Costs: Expenses related to the handling and management of packaging materials.

Step 5: Consider Shipping and Distribution Costs

Calculate the cost of getting your packaged product to the market:

- Transportation Costs: Freight and shipping expenses.

- Packaging Efficiency: Consider how packaging size and weight impact shipping costs.

Step 6: Assess Environmental Impact Costs

Evaluate costs related to the environmental impact of your packaging:

- Recycling and Disposal: Costs of disposing of or recycling packaging materials.

- Carbon Footprint: Potential costs or savings from environmental impacts.

Step 7: Analyze and Optimize

With all data gathered, analyze where costs can be reduced:

- Compare Suppliers: Look for cost-effective suppliers without compromising quality.

- Efficiency Improvements: Identify ways to streamline the packaging process to reduce costs.

- Bulk Purchasing: Consider larger orders to reduce unit costs.

If you are interested in cost effective packaging solutions, then partner with Brown Packaging today to get started.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Home » How To Conduct a Cost Analysis on Your Packaging

With tariffs set to reshape the U.S. packaging industry in 2025, packaging buyers must understand their potential benefits and challenges. Tariffs aim to encourage domestic

The holiday season pushes packaging supply chains to their limits. With surging e-commerce demand, constrained carrier capacity, and rising material costs, packaging buyers must navigate

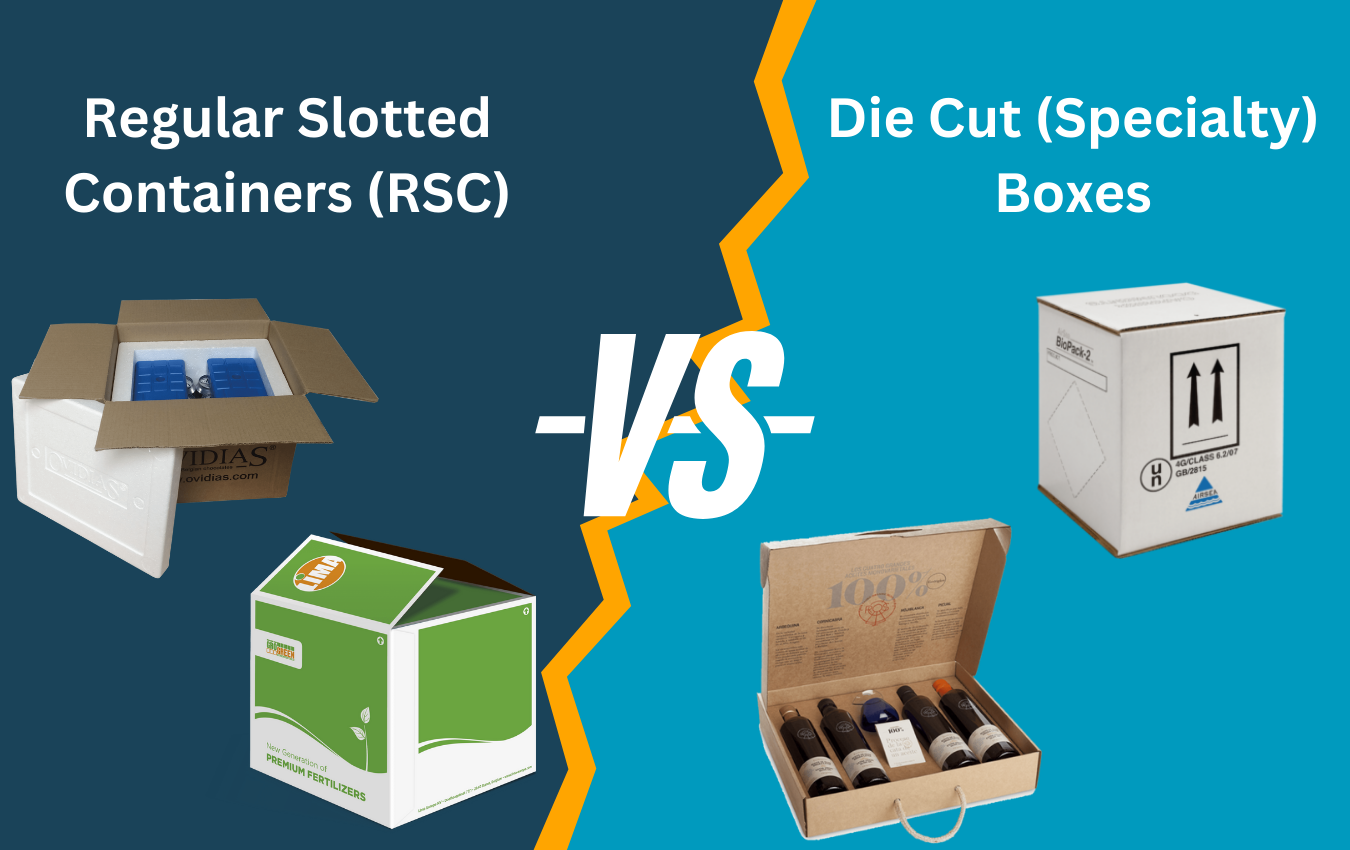

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer