Home » How Structural Design Reduces Packaging Cost

How Structural Design Reduces Packaging Cost

In today’s competitive market, packaging affordability doesn’t start with cheaper materials — it starts with smarter design. Every score, fold, and insert decision affects not only how a box looks and feels, but how efficiently it’s made, shipped, and used.

Structural engineering is the silent driver of cost efficiency — optimizing strength, space, and performance before the first sheet is ever printed.

Why Structure Matters More Than You Think

The most impactful cost savings in packaging rarely come from supplier discounts; they come from structural efficiency.

A box that uses 10% less board but maintains the same compression strength directly reduces both material and freight cost. A redesigned insert that eliminates the need for secondary packaging saves time and labor at the line.

Every cut line and fold path tells a story of cost, sustainability, and brand care — and when those align, affordability becomes part of your brand’s DNA.

Designing for Efficiency, Not Excess

In a market saturated with overbuilt packaging, engineering restraint is a competitive advantage. Structural teams now rely on 3D CAD modeling and virtual prototyping to simulate performance before production — identifying unnecessary material use and structural redundancies.

Through precision die-line planning, engineers can improve sheet yield, reduce assembly time, and minimize void space — the dead air that drives up freight bills.

It’s not about doing less; it’s about doing smarter.

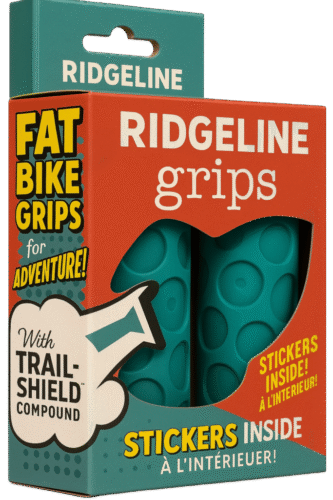

Balancing Protection and Presentation

The temptation to “overprotect” products is common — especially in fragile or high-value goods. But protection doesn’t have to mean bulk. Strategic reinforcements, engineered fluting, and interlocking designs can maintain crush resistance and shock absorption while reducing total board weight.

For e-commerce and shelf packaging alike, brands can achieve premium presentation with structural simplicity — a key to making packaging both sustainable and affordable.

Prototyping to Prevent Waste

Prototyping isn’t just for aesthetics — it’s a safeguard against costly production errors.

With short-run sample testing and performance mockups, brands can evaluate fit, function, and protection early in development. Adjusting dimensions by fractions of an inch can save thousands in material waste and prevent rejected runs down the line.

Smart packaging buyers now view prototyping not as an expense, but as a cost-control strategy that pays dividends in scale.

How Structural Design Supports Brand and Budget

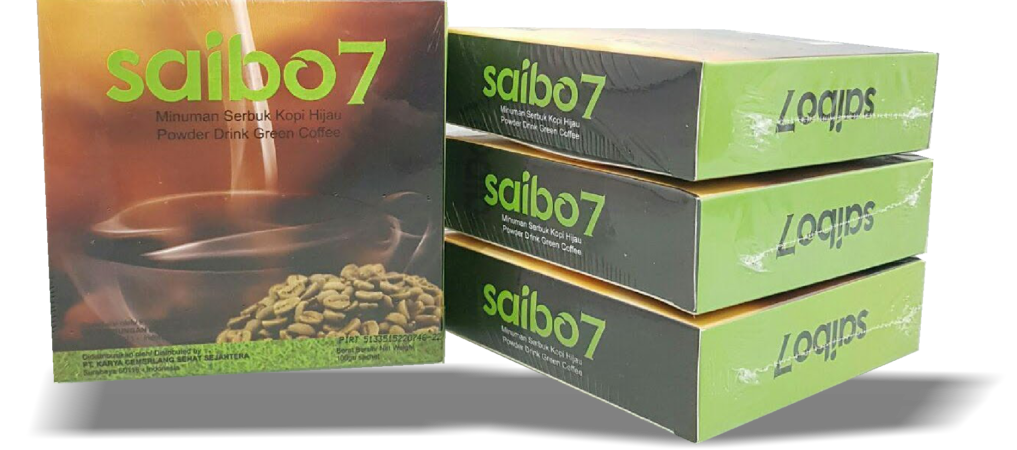

Affordable design doesn’t mean compromising brand identity — it means integrating brand goals into structure. A well-engineered box reinforces trust, ensures product consistency, and communicates value through precision and fit.

When structure, design, and production align, packaging stops being a cost and starts becoming a business asset. That’s where the real savings live — and where long-term brand equity begins.

The Brown Packaging Difference

At Brown Packaging, every packaging solution starts with structural intent — not guesswork.

Our engineering and design teams collaborate to create packaging that performs across shipping, retail, and automation lines, balancing protection, brand visibility, and cost efficiency.

We don’t cut corners; we cut waste.

That’s how our clients achieve packaging that’s not just affordable — it’s engineered to perform.

References

- Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

- PMMI. (2024). Optimizing Structural Design for Packaging Efficiency.

- Packaging World. (2025). Engineering the Future of Cost-Effective Packaging.

- Smithers. (2025). Packaging Innovation and Material Efficiency Trends.

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Home » How Structural Design Reduces Packaging Cost