Home » How Litho Labels Elevate Rigid Box Packaging

How Litho Labels Elevate Rigid Box Packaging

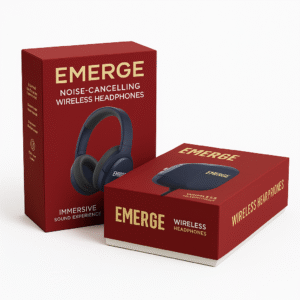

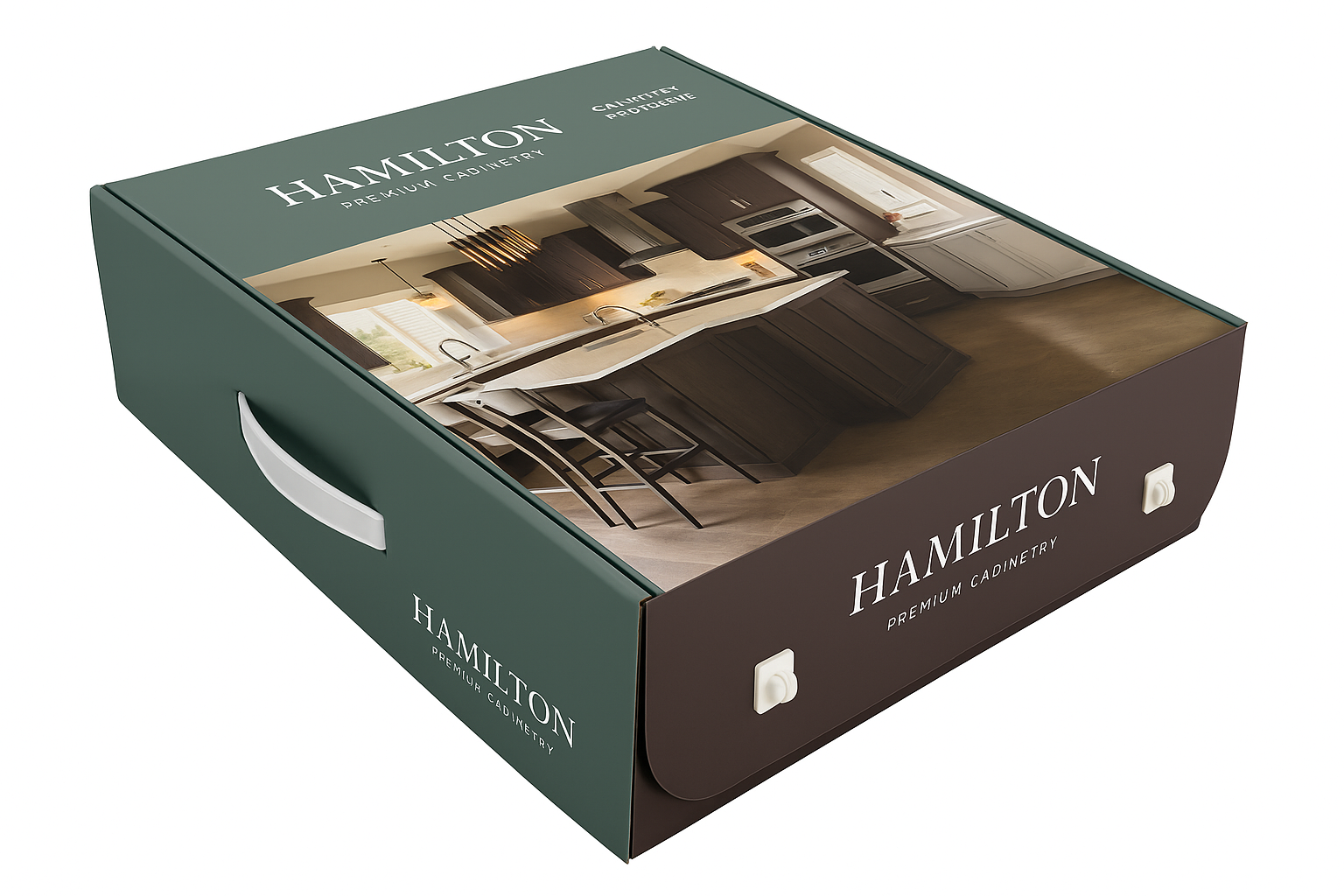

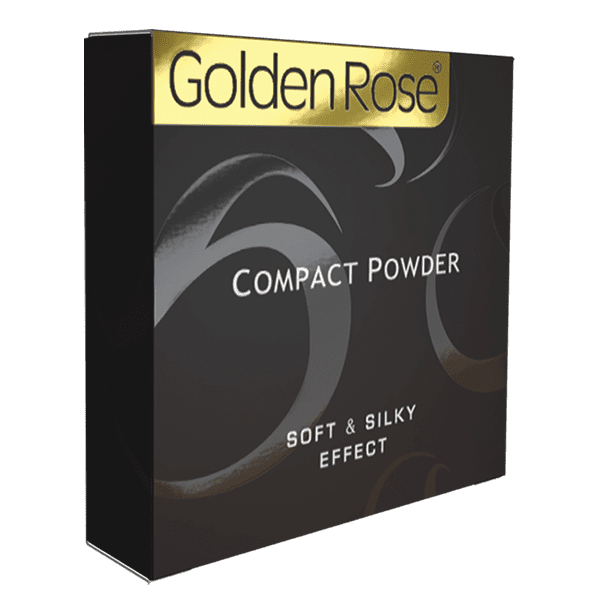

Rigid boxes are known for their durability, structure, and high-end feel—but what truly gives them their luxury appeal is the finish. That polished, vibrant exterior you see on high-end packaging? That’s often thanks to a litho label—a printed sheet that’s mounted to the box surface to deliver rich detail, bold color, and elevated texture.

In this blog, we’ll explore what litho labels are, why they’re commonly used on rigid boxes, and how they can transform your packaging into a premium brand experience.

What Is a Litho Label?

A litho label (short for lithographic label) is a high-resolution printed sheet—usually made from paper or specialty stock—that’s adhered to the surface of a rigid box using glue or mounting equipment.

Litho labels are produced using offset (lithographic) printing, which is known for:

- Crisp detail

- Vivid color accuracy

- Smooth gradients and photo-quality imagery

- Compatibility with coatings like gloss, matte, or soft-touch

Once printed, the label is mounted onto the rigid box, giving it a refined appearance that can’t be achieved through direct-to-board printing.

Why Litho Labels Are Ideal for Rigid Boxes

Rigid boxes are made from thick, dense paperboard (often chipboard), which isn’t suitable for high-quality direct printing. Litho labels solve that by providing a premium printed surface that wraps the box cleanly.

Benefits of Litho Labels on Rigid Boxes:

✅ Photo-Quality Graphics

Perfect for showcasing detailed artwork, branding, or imagery that reinforces luxury positioning.

✅ Wide Range of Finishes

Litho labels can be laminated or coated with gloss, matte, soft-touch, or spot UV, depending on your aesthetic.

✅ Tactile Enhancement

Embossing, debossing, and foil stamping can be applied on top of the label for even more depth and visual interest.

✅ Consistent Quality Across Batches

Offset printing offers high repeatability, making litho labels ideal for brands that demand precision and consistency.

Popular Applications for Litho-Labeled Rigid Boxes

You’ll find litho labels in nearly every premium category, especially where first impressions and unboxing matter.

Common uses include:

- Cosmetics & skincare kits

- Premium electronics packaging

- Subscription or influencer boxes

- High-end spirits or beverage boxes

- Luxury fashion or accessories

- Gift boxes and holiday promotions

Whether displayed in-store or shipped DTC, litho-labeled rigid boxes instantly elevate the perceived value of the product inside.

Design Freedom and Branding Possibilities

Because litho labels are printed before they’re applied, they give you more flexibility in design than other packaging types. You can:

- Use full-bleed artwork and photo backgrounds

- Add intricate patterns or subtle gradients

- Include metallic inks or layered finishes

- Create seamless designs across lids and bases

This allows your packaging to act as an extension of your brand—not just a container, but a premium visual statement.

When Should You Use Litho Labels?

If you’re investing in rigid box packaging and want to maximize visual impact, litho labels are the industry standard. They’re the right choice when:

- Your brand prioritizes premium presentation

- You need high-definition imagery or color matching

- Your packaging will be seen in high-end retail environments

- You’re building a luxury unboxing experience for influencers or direct customers

For mid-range or mass-market packaging, simpler wraps or direct-to-board printing may suffice—but when presentation drives perception, litho-labeled rigid boxes deliver.

Final Thoughts

Litho labels bring rigid boxes to life. They combine the strength and structure of rigid packaging with the visual impact of high-end print finishes, making them a top choice for brands that want to stand out on the shelf—and in customers’ hands.

Ready to create a premium rigid box with litho labeling?

We’ll help you design the perfect combination of structure, print, and finish to match your product’s value and your brand’s voice.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » How Litho Labels Elevate Rigid Box Packaging