Home » Guide To Poly Lamination Foam in Packaging

Guide To Poly Lamination Foam in Packaging

Packaging is a crucial component of product safety and marketing. Over the years, innovative materials have surfaced to enhance packaging capabilities, with one of the most effective being poly lamination foam. This versatile material, extensively used in the packaging industry, delivers unparalleled protection while offering significant cost benefits. In this comprehensive guide, we will delve deep into the world of poly lamination foam, exploring its unique properties, uses, and benefits.

Poly Lamination Foam: An Introduction

Let’s begin by breaking down what poly lamination foam is and how it is created.

- Polyethylene Foam: This is a foam’s structure consists of encapsulated bubbles that provide resilience, strength, and excellent shock absorption.

- Lamination: In this process, a protective layer is adhered to the foam, enhancing its durability, aesthetic appeal, and resistance to elements like moisture and dirt.

Together, poly lamination foam offers a high-performance packaging solution, ensuring that products reach their destination in the best possible condition.

The Strengths of Poly Lamination Foam

Poly lamination foam offers numerous strengths that make it a preferred choice for packaging solutions.

- Durability: Thanks to the lamination process, this material is highly resistant to tearing, puncturing, and general wear-and-tear. It can withstand multiple impacts without compromising its integrity, making it ideal for protecting delicate or valuable goods.

- Moisture Resistance: Poly lamination foam is impervious to water, providing an excellent barrier against moisture and humidity. This feature makes it an excellent choice for products that are sensitive to such conditions.

- Lightweight: Despite its robust protection, poly lamination foam is incredibly lightweight, contributing to reduced shipping costs.

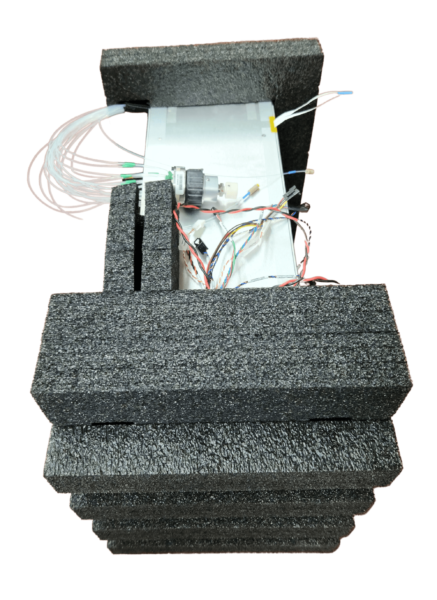

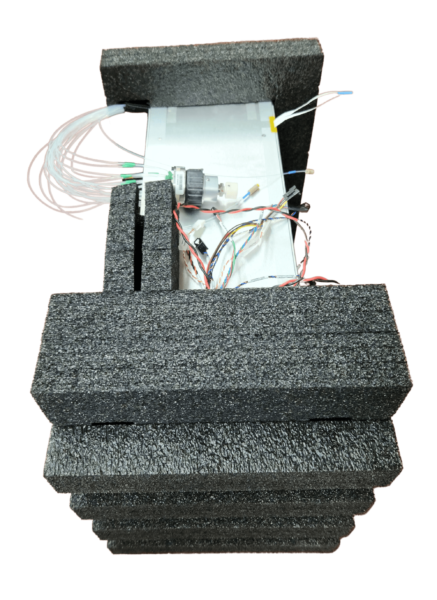

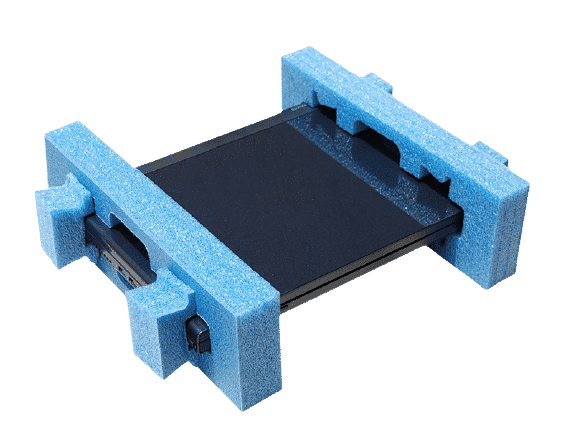

- Versatility: Poly lamination foam can be cut, shaped, and molded to fit a wide variety of products, making it a versatile choice for all types of packaging needs.

Poly Lamination Foam in Various Industries

With its myriad of benefits, poly lamination foam has found extensive use across various industries.

- Electronics: With electronics becoming more intricate and sensitive, they require robust packaging solutions. Poly lamination foam offers superior protection against shock, vibration, and static electricity, ensuring safe transport of these delicate items.

- Medical: In the healthcare industry, the safety of medical devices, pharmaceuticals, and diagnostic equipment is paramount. Poly lamination foam’s protective qualities make it ideal for this sector.

- Automotive: Automotive parts can be heavy, bulky, and delicate. Poly lamination foam is capable of providing the cushioning and protection needed during their transportation.

- Cosmetics: The cosmetics industry often needs to transport delicate bottles and containers. The foam’s ability to be customized allows for a perfect fit, reducing the risk of breakage.

If you are interested in poly lamination foam for your packaging applications, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Guide To Poly Lamination Foam in Packaging

Packaging is a crucial component of product safety and marketing. Over the years, innovative materials have surfaced to enhance packaging capabilities, with one of the

Packaging foam is essential for protecting products against shocks, vibrations, and other potential damages during transportation and storage. Understanding the different types of packaging foam

In packaging, foam isn’t just about initial protection — it’s about maintaining performance over the entire shipping or storage cycle. Compression set and recovery characteristics