Home » Gaylord Boxes Explained: Understanding its Uses and Benefits

Gaylord Boxes Explained: Understanding its Uses and Benefits

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But what exactly is a Gaylord box, and why is it such a prominent player in logistics? In this comprehensive guide, we’ll dive into the world of Gaylord boxes, exploring their definition, common applications, advantages, and considerations for integrating them into your supply chain.

Defining the Gaylord Box: More Than Just a Name

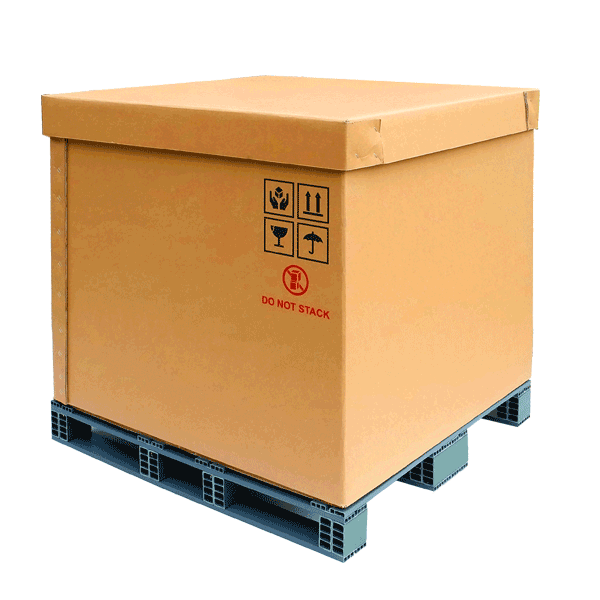

A Gaylord box, often referred to simply as a Gaylord or Gaylord container, is a large, industrial-sized container designed for storing, transporting, and shipping bulk materials. These boxes are typically made from corrugated cardboard, plastic, or metal and come in a variety of sizes, ranging from around 2 feet to over 6 feet in height. The term “Gaylord” was originally a trademarked brand name that has become synonymous with this type of container.

Common Applications of Gaylord Boxes: Versatility Unveiled

Gaylord boxes find their application across a wide range of industries, each benefiting from their versatility and capacity. Some common sectors where Gaylord boxes are extensively used include:

- Manufacturing and Distribution: In manufacturing facilities and distribution centers, Gaylord boxes are utilized to efficiently transport raw materials, components, and finished products within the premises or to customers.

- Agriculture and Produce: For farms and agricultural operations, Gaylord boxes prove invaluable for packing and transporting fruits, vegetables, grains, and other harvested produce.

- Recycling and Waste Management: In recycling centers, Gaylord boxes become collection points for recyclable materials such as paper, plastic, and metal, streamlining the recycling process.

- Retail: In the retail sector, Gaylord boxes are employed to consolidate and transport goods from distribution centers to retail stores or directly to fulfillment houses.

- Automotive Industry: From auto parts to components, Gaylord boxes play a significant role in the storage and transportation of various automotive materials.

- Textile and Apparel: In the textile and apparel industry, Gaylord boxes provide a solution for packing and transporting fabrics, clothing, and other textiles.

- Construction and Building Materials: For the construction industry, Gaylord boxes are used to transport and store construction materials like tiles, bricks, and aggregates.

Advantages of Gaylord Boxes: Unveiling the Benefits

The popularity of Gaylord boxes can be attributed to several key advantages they offer:

- Bulk Handling: Gaylord boxes are designed for bulk storage and transport, making them an efficient choice for handling large quantities of materials.

- Stackability: The sturdy construction of Gaylord boxes allows for safe stacking, optimizing storage space in warehouses and trucks.

- Cost-Effective: Using Gaylord boxes for bulk shipping can often be more cost-effective than using individual smaller containers, reducing packaging and transportation expenses.

- Eco-Friendly Options: Many Gaylord boxes are made from recyclable materials, aligning with sustainability goals and reducing environmental impact.

- Durability: With their robust construction, Gaylord boxes are built to withstand the rigors of transportation and storage, protecting the contents from damage.

- Customizability: Gaylord boxes can often be customized with features such as flaps, access doors, and liners to suit specific needs.

Considerations for Integrating Gaylord Boxes: Tailoring to Your Needs

When considering the integration of Gaylord boxes into your operations, it’s important to take the following factors into account:

- Material Type: Choose the right material (cardboard, plastic, or metal) based on the type of materials you’ll be storing or transporting and the durability required.

- Size and Capacity: Select the appropriate size and capacity of Gaylord box that aligns with your specific needs and available storage or shipping space.

- Usage Environment: Consider the environment in which the Gaylord boxes will be used—whether it’s indoors, outdoors, or in temperature-sensitive conditions.

- Customization Needs: Evaluate whether you require any customization features, such as access doors, flaps, or liners, to enhance the functionality of the box.

- Sustainability Goals: If sustainability is a priority for your organization, opt for Gaylord boxes made from recyclable or eco-friendly materials.

If you are interested in stock or custom gaylord boxes, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Home » Gaylord Boxes Explained: Understanding its Uses and Benefits

When it comes to packaging fragile or valuable items, ensuring their safe transportation is crucial. One effective way to protect these items during shipping or

Corrugated boxes are strong because of their unique construction, which features a fluted corrugated sheet sandwiched between two flat linerboards. This design creates a robust

Corrugated boxes are one of the most popular packaging materials used by businesses worldwide to ship and store their products. They are made of corrugated