Home » Establishing Brand Differentiation With Packaging

Establishing Brand Differentiation With Packaging

In today’s crowded marketplace, where consumers are overwhelmed with choices, establishing differentiation is crucial for any brand’s success. One of the most effective ways to stand out is through innovative and distinctive packaging. This blog post will explore strategies for leveraging packaging as a tool to differentiate your products in a saturated market.

Understanding the Power of Packaging in Market Differentiation

Packaging is not just a means to protect and contain a product; it’s a critical marketing tool. It communicates your brand’s message, values, and identity. In a saturated market, unique packaging can be the deciding factor that sways consumer preference and drives purchase decisions.

Strategies for Differentiating Packaging

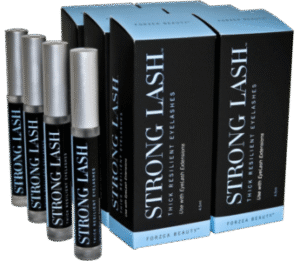

- Bold and Unique Design:

- Use eye-catching designs and color schemes that differentiate your product from competitors. Think outside the traditional aesthetics of your category to captivate attention.

- Incorporate unique shapes, sizes, or textures in your packaging design. Unconventional packaging can intrigue consumers and encourage them to take a closer look.

- Innovative Materials and Sustainability:

- Opt for innovative materials that not only protect the product but also align with emerging consumer preferences, like sustainability.

- Utilize eco-friendly materials, such as biodegradable plastics or recycled paper, to appeal to environmentally conscious consumers.

- Customization and Personalization:

- Offer personalized packaging options. This could range from personalized labels to customizable packaging designs.

- Limited editions and seasonal packaging can create a sense of exclusivity and novelty.

- Interactive and Smart Packaging:

- Integrate technology into your packaging, such as QR codes, AR elements, or NFC tags. This adds an interactive layer to your product, enhancing customer engagement.

- Use smart packaging to provide additional product information, tell your brand’s story, or offer a unique digital experience.

- Clear and Consistent Branding:

- Ensure your packaging clearly communicates your brand identity. Consistent use of logos, colors, and imagery helps build brand recognition.

- Packaging should reflect the brand’s personality, whether it’s luxury, playful, eco-conscious, or cutting-edge.

- Functionality and Convenience:

- Design packaging that adds functional value. For example, resealable or easy-to-open packaging can be a significant differentiator.

- Consider the end-user experience. Packaging that simplifies storage, usage, or disposal can offer an edge over competitors.

- Storytelling Through Packaging:

- Use your packaging to tell a story. This could be the history of your brand, the journey of your product, or the ethos behind your company.

- Storytelling can create an emotional connection with consumers and make your product more memorable.

Market Research and Consumer Insights

- Conduct thorough market research to understand what resonates with your target audience.

- Stay updated with current trends in packaging and consumer preferences.

- Collect feedback on your packaging and continually refine based on consumer insights.

Testing and Prototyping

- Before a full launch, test different packaging designs in focus groups or small market segments to gauge consumer response.

- Use prototyping tools to visualize and modify packaging designs efficiently.

If you are interested in brand differentiation for your product and packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Establishing Brand Differentiation With Packaging

Tampering and theft are significant concerns for manufacturers and consumers alike. Tampered products can pose health and safety risks, while theft results in financial losses.

In the business landscape, the significance of packaging extends far beyond mere aesthetics or basic product protection. It plays a crucial role in branding, customer

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized