Home » Engineering Folding Carton Features

Engineering Folding Carton Features

Functional features like tear strips, windows, and hang tabs can enhance consumer experience and retail appeal—but they also introduce engineering challenges. Each modification affects structural strength, converting efficiency, and cost. This guide examines the technical considerations behind these common folding carton enhancements.

Tear Strips

Tear strips provide controlled access while maintaining tamper evidence until opened.

Engineering Considerations:

- Placement: Must be positioned where it aligns with grain direction to avoid unpredictable tearing.

- Substrate Reinforcement: Removal of fibers weakens the panel; select caliper and fiber strength to compensate.

- Activation Features: Starter notches or pull tabs improve usability but require precise die-cut tolerances.

Applications: Snack boxes, e-commerce ready-packaging, and promotional multi-packs.

Windows

Die-cut or film-covered openings that provide product visibility.

Engineering Considerations:

- Board Strength Loss: Removing material reduces panel rigidity—reinforce with flanges or use thicker caliper.

- Film Selection: Polyester (PET) for clarity and strength; polypropylene (PP) for flexibility and cost savings.

- Attachment Method: Heat sealing for hermetic barriers; cold glue for standard retail windows.

Applications: Bakery cartons, toy packaging, premium electronics.

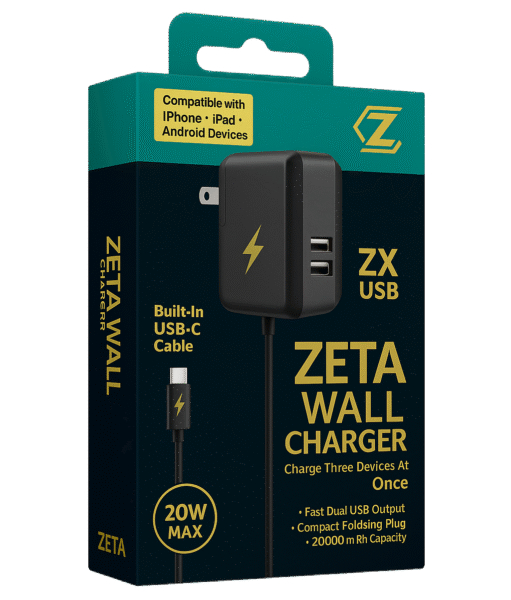

Hang Tabs

Extensions with die-cut holes designed for pegboard display.

Engineering Considerations:

- Load Bearing: Must withstand repeated handling without tearing; reinforced with lamination or added plies.

- Hole Shape: Rounded edges distribute stress better than sharp corners.

- Placement: Maintain center alignment for balance during display.

Applications: Small electronics, blister card sleeves, impulse-buy products.

Score and Perforation Modifications

Used for easy-open panels or controlled folding in promotional displays.

Engineering Considerations:

- Perforation Pattern: Ratio of cut-to-land determines tear resistance.

- Score Depth: Must be consistent to avoid tearing in unintended areas.

- Coating Impact: Gloss or film coatings may require modified perforation tooling for clean separation.

Impact on Production Efficiency

- Die-Cutting Complexity: Additional features increase make-ready time and tooling wear.

- Feeding and Folding: Non-standard cutouts may catch on machine guides—prototype testing is critical.

Waste Management: Window scrap and added features increase offcut volume.

Balancing Aesthetics, Function, and Strength

Every feature trades some structural integrity for consumer or retail benefit. The engineering goal is to design enhancements that maximize usability and shelf presence without compromising carton performance or running efficiency.

References

Soroka, W. (2014). Fundamentals of packaging technology (5th ed.). Institute of Packaging Professionals. ISBN: 978-1-930268-37-2

Twede, D., & Goddard, R. (2021). Cartons, crates and corrugated board: Handbook of paper and wood packaging technology (2nd ed.). DEStech Publications. ISBN: 978-1-60595-120-5

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Engineering Folding Carton Features