Home » Effective Print Strategies for Packaging: A Buyer’s Guide

Effective Print Strategies for Packaging: A Buyer’s Guide

In today’s market, the printing strategy employed on packaging can play a significant role in a product’s success. This guide is tailored to help buyers navigate the array of print options available, ensuring they select the most effective strategy to enhance brand appeal and customer engagement, while balancing cost and quality.

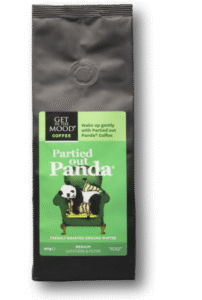

High-Quality Graphics and Imagery

The use of high-resolution graphics and vibrant imagery makes packaging more attractive and attention-grabbing. Ensuring that these elements are of the highest quality will reflect well on the product and brand.

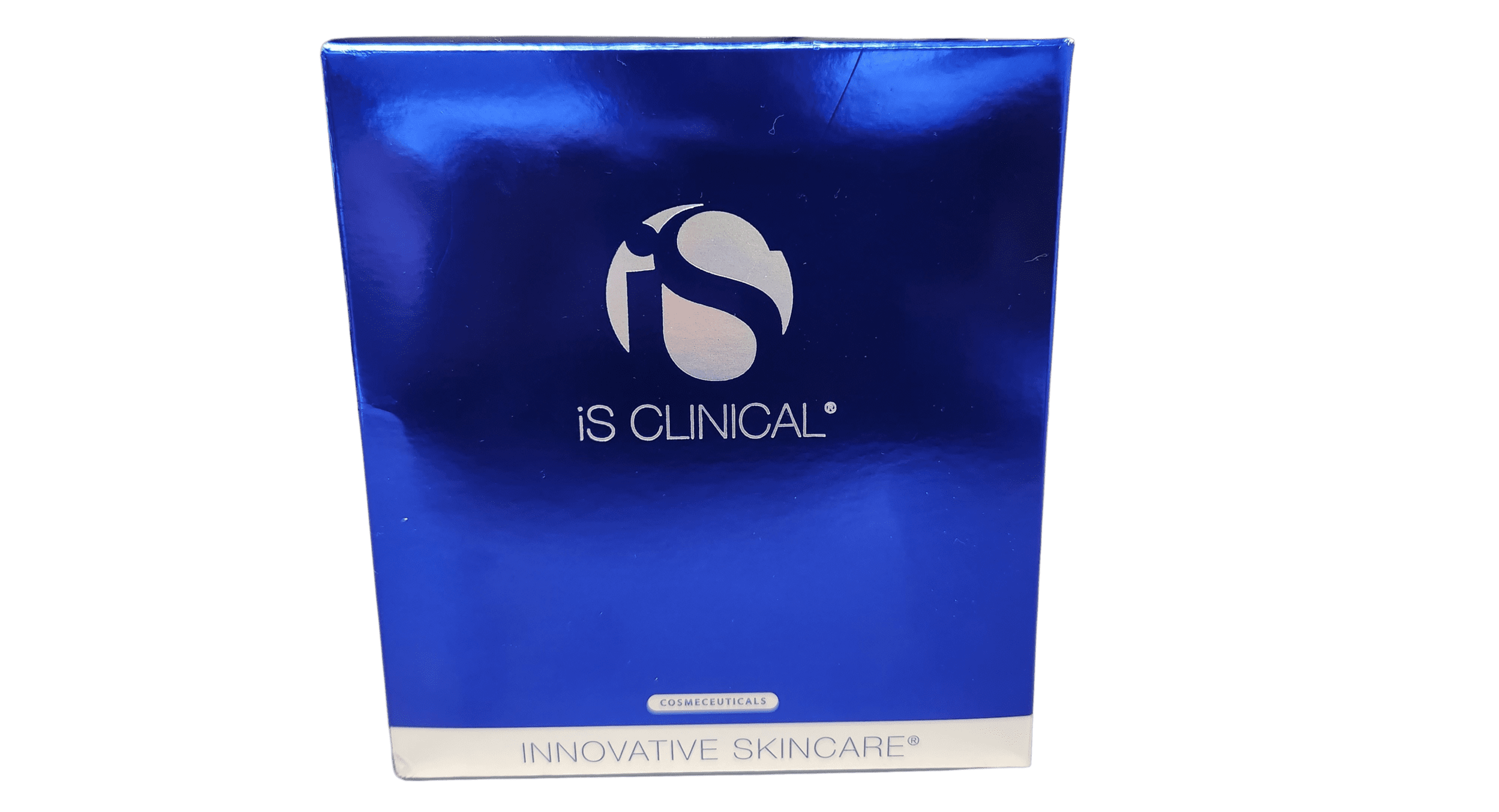

Brand Consistency

Maintaining consistency with brand colors, logos, and typefaces across all packaging is essential. This consistency helps in reinforcing brand recognition and loyalty among customers.

Cost-Effective Printing Techniques

- Digital Printing: Ideal for short to medium runs, offering cost savings for smaller orders and flexibility for design changes.

- Flexographic Printing: Cost-effective for larger runs, it provides durability and consistency, especially for standard designs.

Sustainable Printing Practices

Eco-friendly practices are not just good for the environment but also resonate with modern consumers. Utilize sustainable inks and materials wherever possible. Providers who offer soy or vegetable-based inks and recycled materials can help in positioning your brand as environmentally responsible.

Interactive Elements

Incorporating QR codes or augmented reality features can make packaging more engaging. These elements can lead consumers to additional digital content, enhancing brand interaction and providing more product information.

Tactile Printing Techniques

Techniques like embossing or debossing add a tactile element to packaging, enhancing the unboxing experience. Foil stamping can also be used to add a premium feel to the product.

Typography and Readability

Creative and legible typography is key to conveying the product’s message. Different font styles and sizes can be used to create emphasis and a hierarchy of information, making it easier for consumers to access key details.

Return on Investment (ROI)

Consider the long-term ROI when selecting a print strategy. High-quality printing might cost more upfront but can lead to greater brand recognition and customer loyalty. Evaluate how different printing options can impact the overall budget and balance them against the potential long-term benefits.

Customization Options

Digital printing and other modern techniques offer extensive customization options, allowing for unique packaging designs that can set a product apart in the marketplace.

Evaluating Print Providers

Choosing the right print provider is crucial. Look for partners who offer not only quality assurance and a wide range of capabilities but also have a robust portfolio and positive client testimonials. It’s important that they understand your industry’s specific needs and offer exceptional customer service.

If you are interested in printed packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Effective Print Strategies for Packaging: A Buyer’s Guide

Packaging is an essential aspect of any product’s marketing strategy. It is often the first point of contact with the consumer and can greatly influence

The world of packaging design has undergone a remarkable transformation in recent years, with new and innovative designs emerging to meet the ever-changing needs of

High-speed automated packaging lines can run hundreds of cartons per minute, but only if the carton’s design and material are optimized for smooth feeding, folding,