Home » Edge Crush Testing: Corrugated Packaging Strength and Durability

Edge Crush Testing: Corrugated Packaging Strength and Durability

Packaging plays a crucial role in protecting products during transportation and handling. However, not all packaging materials, such as corrugated are created equal, and choosing the wrong materials can lead to damaged or lost products. That’s why testing the strength and durability of packaging materials is crucial to the packaging industry.

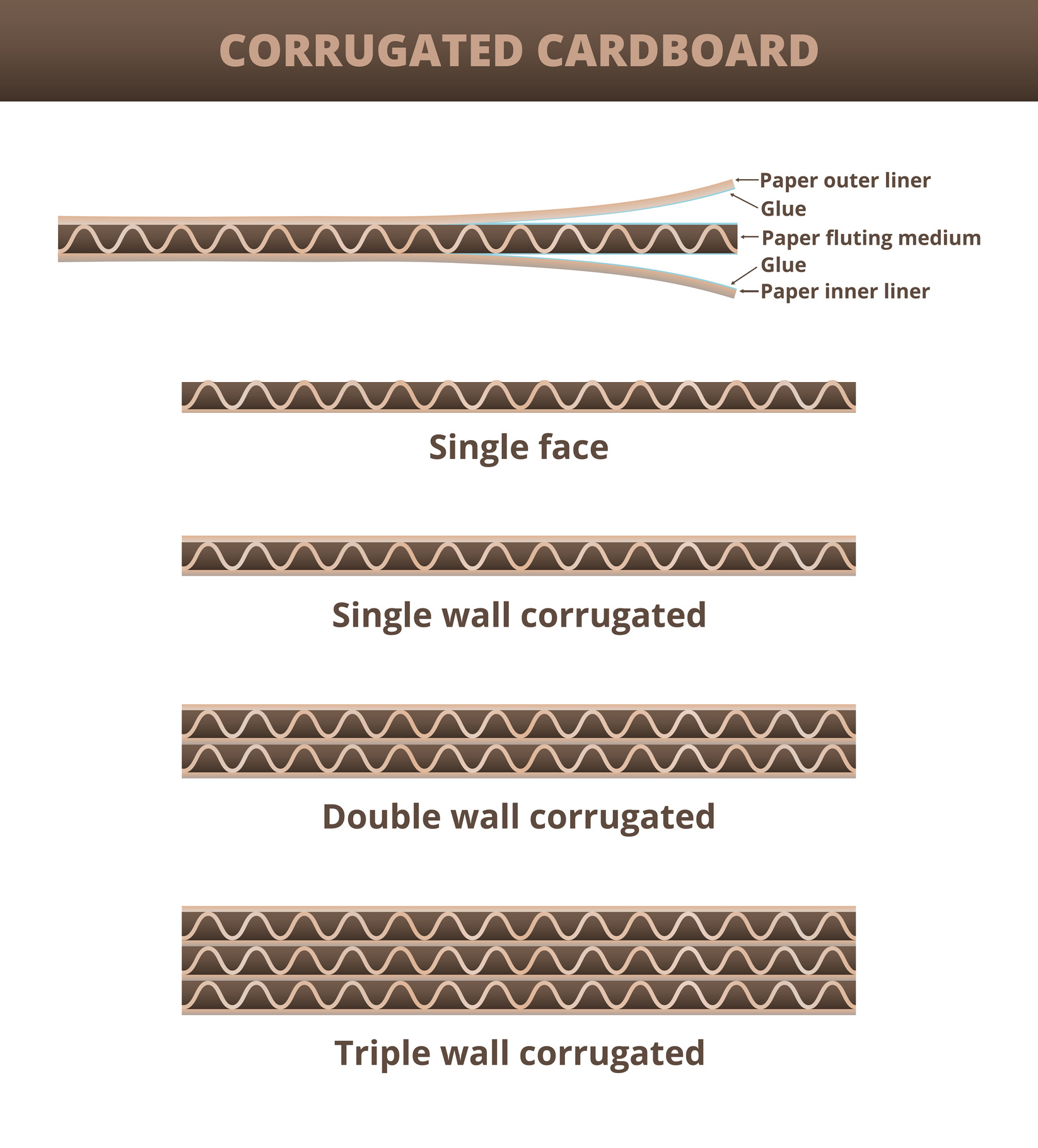

Edge crush testing are processes that measure the strength and durability of packaging materials, particularly corrugated boxes. Corrugated boxes are made of a fluted sheet sandwiched between two flat sheets of paper and are commonly used for shipping and storing products. The strength of the corrugated box depends on the number and size of the flutes, as well as the quality of the paper used.

Corrugated Strength and Durability

The strength and resistance of corrugated board is determined by the maximum force that the board can withstand before collapsing, known as the compression strength. These board consists of a fluted sheet sandwiched between two flat sheets of paper, providing cushioning and support. Various types of flutes, such as A, B, C, E, F, and N flutes, offer durability and cushioning options for manufacturers to choose from.

Edge Crush Testing

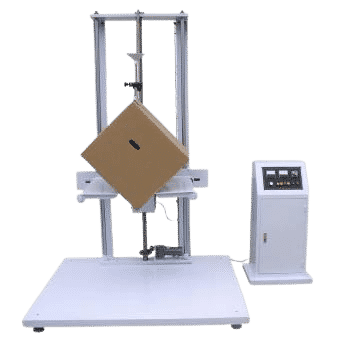

Edge crush testing evaluates the edge crush resistance of corrugated board. It measures the board’s ability to withstand pressure along its edges without collapsing. As the edges of corrugated boxes are often the weakest points, measuring edge crush resistance is crucial. The testing procedure involves compressing a sample of corrugated board between two plates until it fails. The results are expressed in pounds per inch (PPI) or kilonewtons per meter (kN/m).

The Importance of Corrugated and Edge Crush Testing

Corrugated and edge crush testing are essential for several reasons. They help manufacturers and distributors choose the right packaging materials based on the fragility, weight, and dimensions of their products. By conducting these tests, businesses can ensure that their packaging materials can withstand the rigors of transportation and handling, reducing the risk of damage or loss. Additionally, meeting industry standards and regulations is crucial, and these tests help ensure compliance.

To determine the appropriate packaging material strength, factors such as product weight, dimensions, and fragility should be considered. For example, a small, lightweight product with low fragility may require an Edge Crush Test (ECT) rating of 23 or higher. On the other hand, a large, heavy product with high fragility may require an ECT rating of 44 or higher. The chart below illustrates some general recommendations for product weight, dimensions, fragility, and the required ECT rating:

Corrugated Board Strength Equivalencies: Single Wall Corrugated

Corrugated Board Strength Equivalencies: Double Wall Corrugated

** Please note that the additional factors such as dimensions and fragility are general descriptors and may vary depending on the specific product being packaged. It is essential to consider these factors in conjunction with the weight and consult with a packaging expert to determine the appropriate ECT rating for your specific product and shipping needs.**

Benefits of Corrugated and Edge Crush Testing

The benefits of corrugated and edge crush testing extend beyond ensuring product safety during transportation. By using the appropriate packaging materials based on the results of these tests, manufacturers and distributors can experience several advantages.

- Cost Savings: Selecting the right packaging materials reduces the risk of damage or loss during transit, saving businesses costs associated with product replacement, shipping, and customer service.

- Enhanced Product Quality: Using packaging materials that have been tested for strength and durability ensures that products arrive in good condition, enhancing the overall product quality and customer satisfaction.

- Environmental Impact Reduction: Choosing materials that are strong and durable helps minimize waste generation and reduce the environmental impact of packaging operations.

- Brand Image Enhancement: Packaging materials that effectively protect products and deliver them in pristine condition contribute to positive customer experiences, repeat business, and a strong brand image.

Future of Corrugated and Edge Crush Testing

As technology continues to advance, we can expect improvements in the methods and equipment used for corrugated and edge crush testing. These advancements may include enhanced accuracy, faster testing processes, and the ability to test a broader range of materials. The continuous improvement of testing methods will further enhance the reliability and efficiency of these tests, benefiting the packaging industry as a whole.

If you are interested in corrugated packaging that meets your desired edge crush ratings, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Edge Crush Testing: Corrugated Packaging Strength and Durability

A Half Slotted Container (HSC) is a specific type of corrugated box known for its robustness, versatility, and open-top design. These features make HSCs ideal

Corrugated boxes lose a significant portion of their original compression strength during prolonged storage, especially under load. Understanding the mechanics of compression creep and the

Corrugated bin boxes have become a staple in the retail industry, offering a myriad of benefits for both store owners and shoppers alike. At first