Home » Ecommerce: How to Plan for Holiday Packaging

Ecommerce: How to Plan for Holiday Packaging

The holiday season is the most profitable time of year for ecommerce. With increased competition, brands must create a memorable seasonal experience through custom holiday packaging. Strategic holiday packaging not only makes products more appealing but also positions them as ready-to-gift items, helping brands capture greater market share.

Plan for the Holidays Early

Holiday packaging requires advanced planning to avoid missed deadlines. Suppliers, freight carriers, and logistics networks become congested, leaving little room for late adjustments. Ordering early allows time for:

Structural and graphic design revisions

Material sourcing and print lead times

Coordination with freight providers to secure on-time delivery

Focus on Seasonal Products and Gift Bundles

Consumers look for seasonal SKUs and bundled offerings during the holidays.

Seasonal SKUs drive urgency through limited availability and holiday themes.

Gift Bundles provide convenience by combining products into a single package, saving buyers time and effort.

Tracking purchase history helps allocate resources toward SKUs most likely to perform during peak shopping windows.

Incorporate Seasonal Designs

Holiday packaging is not just functional — it’s part of the customer experience. Seasonal graphics can create excitement, improve brand recall, and encourage social sharing.

Ideas for seasonal design include:

Bright and festive colors

Nostalgic or traditional holiday patterns

Sustainable materials and eco-conscious messaging

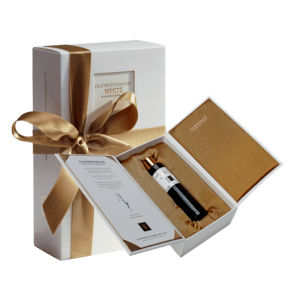

Custom add-ons like stickers, ribbons, tags, or tissue paper

Use Quality Materials

During the holidays, packaging must balance presentation and protection.

Premium materials (rigid boxes, corrugated mailers, luxury bags) enhance gift appeal.

Finishing techniques such as embossing, foiling, and varnishes elevate perceived value.

Stronger substrates protect products in transit during peak shipping volumes.

Quality packaging enhances unboxing experiences, making gifts feel more special while protecting brand reputation.

Work With a Packaging Provider

Partnering with an experienced packaging supplier streamlines the process. A provider can:

Recommend seasonal design approaches

Manage lead times and supply chain coordination

Ensure packaging aligns with ecommerce logistics and retail compliance

This expertise saves time and reduces the risk of delays, helping brands stay competitive during the busiest season.

Work With Brown Packaging

At Brown Packaging, we help ecommerce brands prepare for the holiday rush with custom holiday packaging tailored to seasonal demand. From structural design to premium finishes, our team ensures your packaging communicates value, enhances customer experience, and arrives on time. Contact Brown Packaging today to get started.

References

National Retail Federation (NRF). (2023). Holiday Shopping Trends and Consumer Behavior. Retrieved from https://nrf.com

Flexible Packaging Association. (2023). Holiday Packaging Trends in E-commerce. Retrieved from https://www.flexpack.org

Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Ecommerce: How to Plan for Holiday Packaging

The surge of eCommerce has fundamentally altered the methods in which products are bought and sold. Amid these alterations, one element consistently remains vital —

During the holiday season, packaging does more than protect—it directly influences how recipients perceive the gift inside. For e-commerce buyers, the right packaging design can

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies