Home » Double or Single Wall for Boxes: Making the Right Choice

Double or Single Wall for Boxes: Making the Right Choice

When it comes to choosing the right packaging for your products, you’re often faced with various options. One critical decision in the world of packaging is whether to go with double-wall or single-wall boxes. Each has its own set of advantages and considerations. In this detailed blog, we will explore both options, helping you make an informed choice that suits your specific packaging needs.

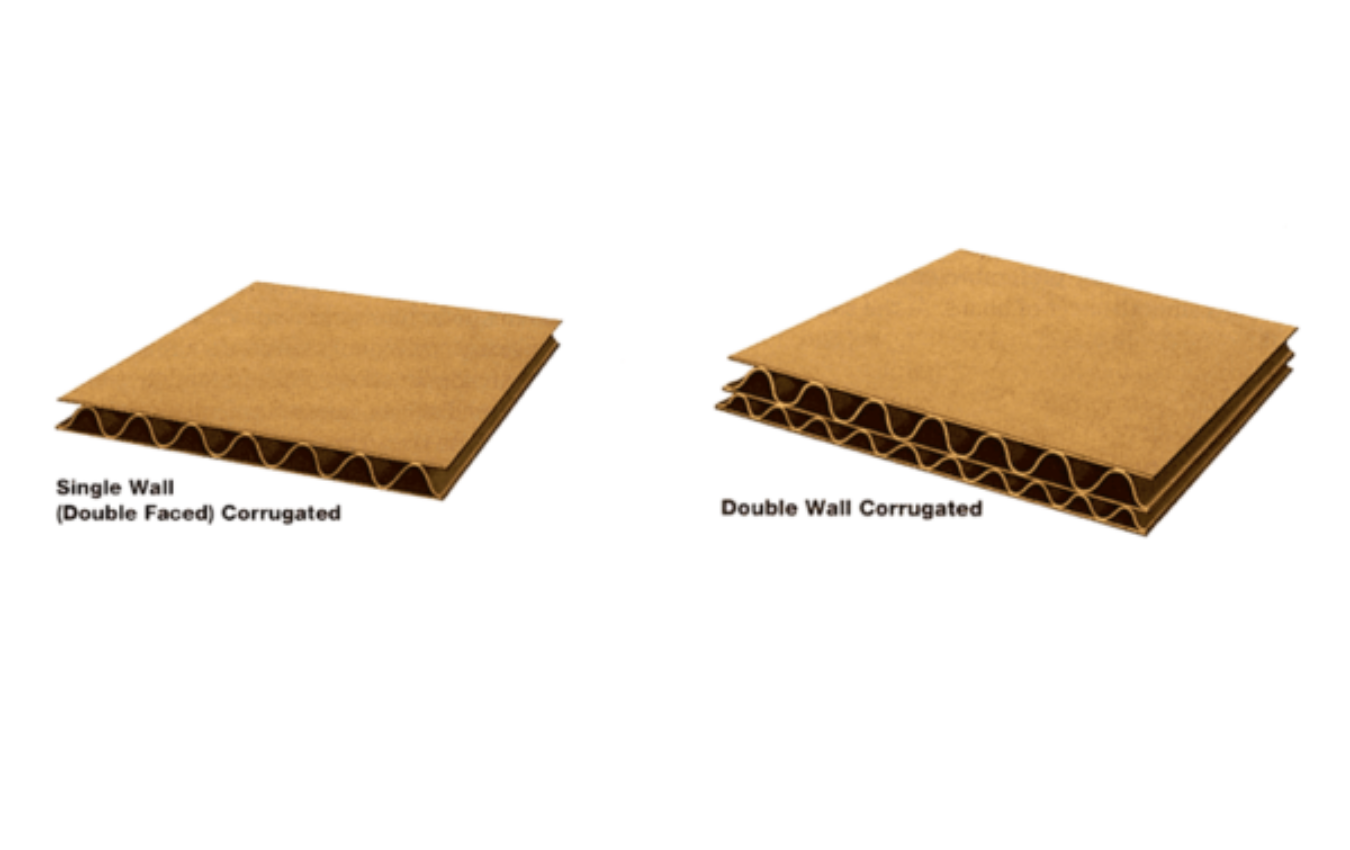

Single-Wall Boxes: The Basics

Single-wall boxes are constructed from a single layer of corrugated cardboard. This makes them lightweight and cost-effective. They are an excellent choice for a wide range of products, especially those that don’t require heavy-duty protection during transportation and storage.

Advantages of Single-Wall Boxes

- Cost-Effective: Single-wall boxes are budget-friendly and suitable for businesses looking to reduce packaging costs without compromising quality.

- Lightweight: Their lightweight nature reduces shipping costs and makes handling easier.

- Versatile: Single-wall boxes can be used for a variety of products, such as clothing, cosmetics, and lightweight electronics.

- Easy to Assemble: They are straightforward to assemble, saving time in the packaging process.

Considerations for Single-Wall Boxes

- Limited Protection: They offer limited protection for fragile or heavy items, making them less suitable for products that require enhanced safety during transit.

- Stacking Strength: Single-wall boxes may not withstand heavy stacking loads as well as double-wall boxes.

Double or Wall Boxes: The Essentials

Double-wall boxes are constructed from two layers of corrugated cardboard, offering increased strength and durability. They are designed to provide superior protection for heavier or fragile products.

Advantages of Double-Wall Boxes

- Enhanced Durability: Double-wall boxes offer superior protection, making them ideal for products that require additional safeguarding during shipping.

- Heavy-Duty: They can withstand heavy stacking loads, reducing the risk of damage to the contents.

- Versatility: Double-wall boxes are suitable for a wide range of products, from electronics and appliances to glassware and ceramics.

Considerations for Double-Wall RETT Boxes

- Cost: Double-wall boxes are generally more expensive than single-wall options due to the additional material and strength.

- Weight: They are heavier, which can increase shipping costs and make handling more challenging.

Choosing the Right Option

The choice between single-wall and double-wall boxes ultimately depends on your specific product and shipping requirements. Here are some factors to consider:

- Product Weight: If your products are heavy or fragile, double-wall boxes provide the necessary protection. For lighter and less delicate items, single-wall boxes may suffice.

- Shipping Distance: For long-distance shipping or international transport, double-wall boxes can offer added security against rough handling and stacking.

- Budget: Consider your budget constraints. Single-wall boxes are more cost-effective, which can be an advantage for businesses looking to reduce packaging expenses.

- Environmental Impact: Think about your commitment to sustainability. Single-wall boxes, being lighter, may have a lower carbon footprint in terms of shipping, while double-wall boxes are sturdier and reusable.

Conclusion

Choosing between single-wall and double-wall boxes depends on your specific packaging needs, product characteristics, and budget considerations. Single-wall boxes are cost-effective and versatile, suitable for lightweight products. Double-wall boxes offer enhanced protection and durability, making them ideal for heavy or fragile items. Assess your unique requirements and make an informed choice to ensure your products are well-protected during transit and storage while staying within your budget constraints.

If you are interested in roll end tuck end boxes, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Double or Single Wall for Boxes: Making the Right Choice

Gift-giving is a timeless tradition, and the packaging plays a crucial role in making the gesture even more special. When it comes to choosing the

In e-commerce, packaging plays a crucial role in ensuring that your products reach customers safely and intact. Whether you’re shipping lightweight apparel or heavy electronics,

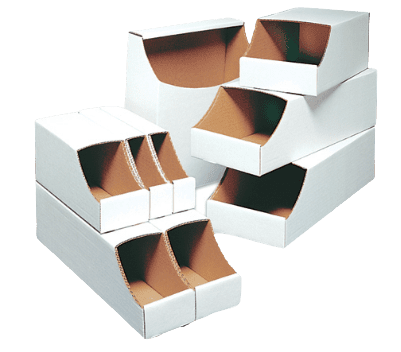

Corrugated bin boxes are widely used for storage and organization, especially in warehouses and retail settings. When used and stacked properly, they offer an efficient