Home » Digital vs. Flexo Print: Which Should You Choose?

Digital vs. Flexo Print: Which Should You Choose?

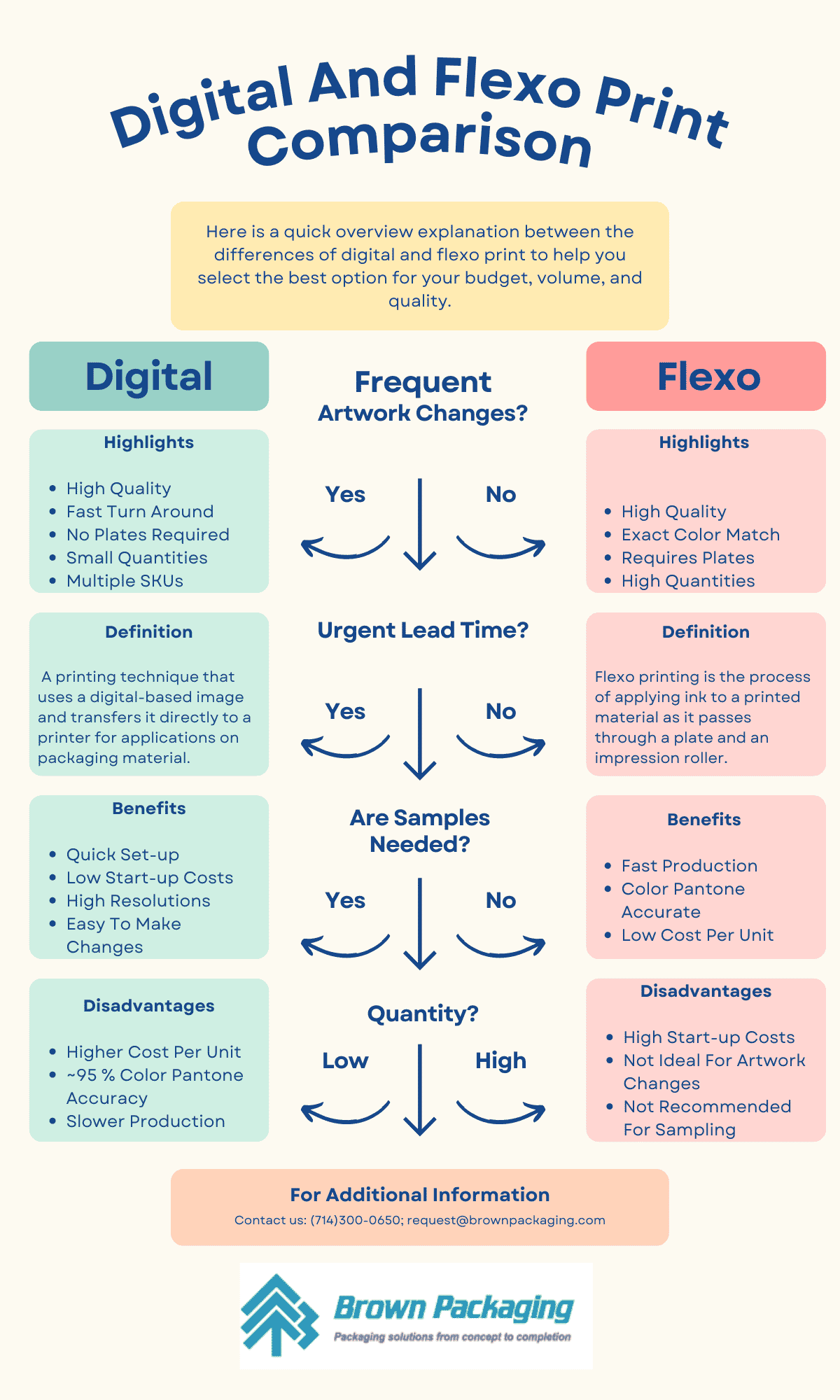

When customizing packaging with logos, brand colors, or designs to enhance product appeal and branding, choosing the right printing technique is crucial. Today’s technology offers several options, each suited to different needs based on budget, volume, and quality requirements. In this guide, we will delve into two popular printing methods—digital and flexographic printing—to help you determine the best option for your packaging needs.

Understanding the Complexity of Custom Packaging

Custom packaging, which can include boxes, pouches, labels, and cartons, is tailored specifically with unique structures, graphics, materials, and features. Unlike standard products, custom packages require considerable time, planning, effort, and investment, providing significant advantages in product protection, efficiency, and marketability.

Digital Printing: Efficiency and Flexibility

Digital printing is a modern technique that transfers a digital-based image directly onto the packaging material using advanced printers. This method is ideal for quick turnaround projects due to its minimal setup requirements.

Advantages of Digital Printing:

- Quick Setup: No need for plates or prolonged setup times, making it perfect for tight deadlines.

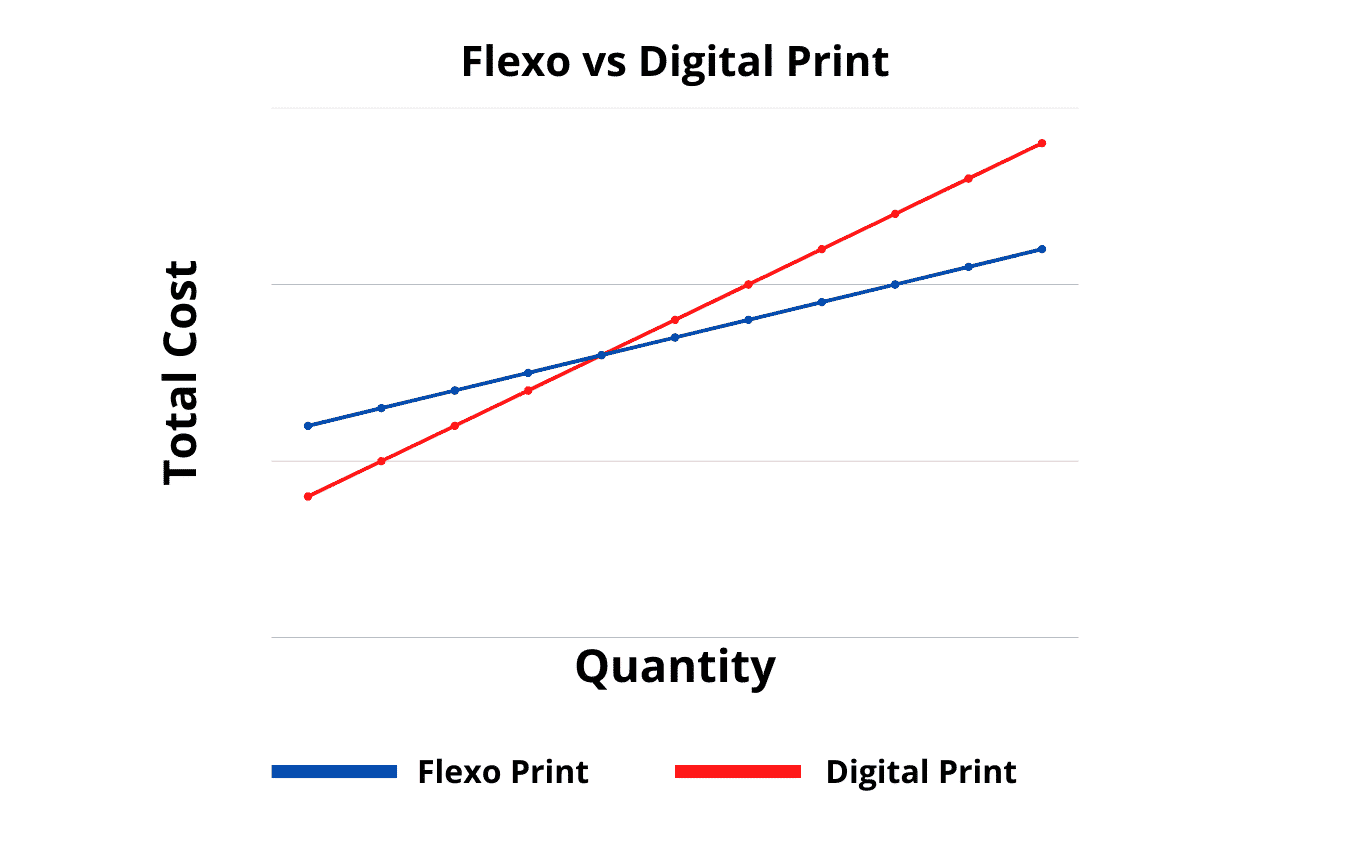

- Cost-Effectiveness for Short Runs: Although the cost per unit is higher, the low initial investment makes digital printing cost-effective for small, customized orders.

- High-Quality Prints: Digital printers can produce detailed, vibrant prints suitable for complex designs and small text.

- Flexibility: Changes to the artwork or design can be made quickly and inexpensively, allowing for frequent updates and iterations.

Ideal Use Cases for Digital Printing:

- Short runs or low volume orders.

- Projects requiring high detail and print quality.

- Customization for limited editions or personalized packaging.

- Prototypes and samples where frequent modifications are expected.

Flexographic Printing: Traditional and Economical

Flexographic printing, or flexo, is a more traditional form of printing that involves the use of rubber or plastic plates to apply ink to the packaging material. This method is favored for its efficiency in high-volume production runs.

Advantages of Flexographic Printing:

- Economical for Large Volumes: High initial setup costs are offset by lower costs per unit, making flexo printing cost-effective for large runs.

- Speed: Once the setup is complete, flexo printing can produce large quantities rapidly.

- Color Accuracy: Flexo is excellent for projects requiring precise color matching, using GCMI or PMS colors to ensure brand consistency.

Ideal Use Cases for Flexographic Printing:

- High-volume printing where the design does not change frequently.

- Projects that require exact color specifications.

- Long-term printing needs where the initial investment in plates can be amortized over time.

Making the Right Choice

The decision between digital and flexo printing depends on several factors:

- Volume: Digital printing is more suitable for smaller quantities, while flexo printing is cost-effective for larger runs.

- Complexity of Design: Digital printing handles complex images and variable data printing more efficiently.

- Color Accuracy: If exact color matching is critical, flexo printing is the preferred choice.

- Budget Constraints: Consider the upfront costs associated with flexo printing versus the potentially higher per-unit costs of digital printing for small runs.

Choosing between digital and flexo printing for your packaging needs involves weighing the specifics of your project against the strengths of each printing method. For rapid, highly customizable small runs, digital printing offers flexibility and speed. For larger, consistent runs where color accuracy and cost efficiency are paramount, flexo printing provides an effective solution. By carefully considering your project’s requirements, you can select the printing technology that best aligns with your operational goals and budget.

If you are interested in flexo or digital print custom packaging, then contact Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Digital vs. Flexo Print: Which Should You Choose?

In the competitive pet care industry, packaging graphics can be as influential as product quality when it comes to driving sales. For pet food, treats,

Rigid boxes are known for their durability, structure, and high-end feel—but what truly gives them their luxury appeal is the finish. That polished, vibrant exterior

Rigid boxes are known for their premium feel, durability, and high-end presentation, making them the go-to choice for luxury goods, cosmetics, electronics, and gift packaging.