Home » Designing Folding Cartons for E-Commerce Shipping Durability

Designing Folding Cartons for E-Commerce Shipping Durability

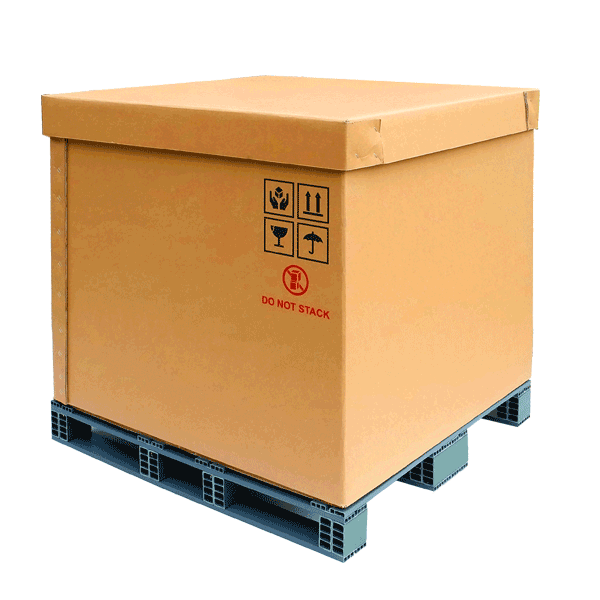

E-commerce exposes folding cartons to more handling points, longer transit times, and harsher mechanical stresses than traditional retail distribution. Designing for these conditions requires careful material selection, structural reinforcement, and testing to ensure the product arrives intact and presentable.

Understanding E-Commerce Transit Hazards

Small-parcel shipping subjects cartons to conditions outside typical retail supply chains:

- Multiple Sorting Touchpoints: Each transfer increases the risk of edge crush and panel denting.

- High Vibration: Long delivery routes and conveyor systems cause sustained shaking.

- Compression Loads: Cartons may be stacked under heavier mixed-weight items in transport.

- Environmental Variability: Temperature and humidity swings in delivery trucks and sorting centers.

(ASTM D4169 simulates these hazards for performance testing.)

Material Selection

- CUK (Coated Unbleached Kraft): Higher tear and puncture resistance, ideal for heavier or rigid products.

- High-Caliper SBS: Provides a smooth print surface while increasing crush resistance.

- Poly-Coated or Moisture-Barrier Boards: Essential for humid climates or cold-chain shipments.

Tip: Avoid over-specifying — choose the lightest grade that meets drop, compression, and vibration requirements.

Structural Reinforcements

- Full Seal End (FSE): Seals both ends for maximum tamper resistance and panel rigidity.

- Auto Bottom: Improves stacking strength while enabling faster manual packing.

- Reinforced Glue Flaps: Wider flaps or added tear-resistant tape in high-stress zones.

- Double-Panel Sides: Layering board at impact-prone edges to reduce corner crushing.

Coatings and Finishes

- Scuff-Resistant Varnish: Maintains appearance after multiple handling points.

- Water-Resistant Coatings: Prevent fiber swelling from rain or condensation.

- Matte Finishes: Reduce visible wear compared to high gloss in transit.

Testing and Validation

- Drop Tests: Simulate handling from waist height at multiple orientations.

- Vibration Testing: Identify structural weaknesses under sustained shaking (ASTM D4728).

- Compression Tests: Ensure cartons can withstand stacking in mixed-weight loads (TAPPI T804).

- Environmental Conditioning: Test under humidity and temperature extremes before market launch.

Cost–Performance Balance

Over-engineering increases per-unit cost and shipping weight. The most durable e-commerce cartons balance material and style to meet ISTA or ASTM testing requirements without exceeding budget targets.

References

ASTM International. (2016). ASTM D4169-16: Standard practice for performance testing of shipping containers and systems. ASTM International. https://doi.org/10.1520/D4169-16

ASTM International. (2016). ASTM D4728-06(2016): Random vibration testing of shipping containers. ASTM International. https://doi.org/10.1520/D4728-06R16

TAPPI. (2017). T 804: Compression test of fiberboard shipping containers. TAPPI Press.

Soroka, W. (2014). Fundamentals of packaging technology (5th ed.). Institute of Packaging Professionals. ISBN: 978-1-930268-37-2

Twede, D., & Goddard, R. (2021). Cartons, crates and corrugated board: Handbook of paper and wood packaging technology (2nd ed.). DEStech Publications. ISBN: 978-1-60595-120-5

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Designing Folding Cartons for E-Commerce Shipping Durability