Home » Customization for Different Segments: A Key Strategy in Packaging

Customization for Different Segments: A Key Strategy in Packaging

In a diverse consumer market, the effectiveness of your packaging strategy can hinge on how well it resonates with specific customer segments. Customization for different segments in packaging allows brands to tailor their approach to meet the unique preferences and needs of various consumer groups. This blog post continues to explore the strategies and benefits of segment-specific packaging customization.

Demographic-Based Customization

- Age Groups: Packaging for different age groups requires distinct design elements. Bright, bold designs may attract a younger audience, while older consumers might prefer sleek, sophisticated packaging.

- Gender-Specific Design: While moving towards more gender-neutral designs is a growing trend, some products might still benefit from gender-specific packaging, using color schemes and imagery that traditionally appeal more to men or women.

Lifestyle and Interest Customization

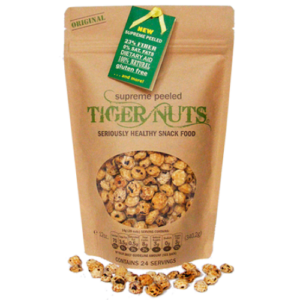

- Hobby or Interest-Based Packaging: Products aimed at specific hobbies or interests can benefit from customized packaging that reflects these activities. For instance, sports equipment packaging can feature athletic imagery and dynamic designs.

- Cultural and Geographic Tailoring: Customizing packaging to reflect local cultures, languages, and symbols can significantly increase its appeal in different geographic markets.

Customization Based on Consumer Behavior

- Eco-Conscious Packaging: For environmentally conscious consumers, using sustainable materials and minimalist designs can make the product more appealing.

- Luxury and Premium Packaging: High-end products can benefit from packaging that exudes luxury through high-quality materials, elegant designs, and exclusive finishes.

Personalization: The Ultimate Customization

- Individualized Packaging: Advances in printing technology have made it possible to create personalized packaging, such as including a customer’s name or a personalized message, which can greatly enhance the customer experience and loyalty.

Technological Integration for Targeted Segments

- Smart Packaging Elements: Incorporating technology like QR codes or augmented reality can appeal to tech-savvy segments, offering them an interactive and informative packaging experience.

Testing and Consumer Feedback

- Market Testing: Before fully committing to a new packaging design for a specific segment, conduct market tests to gauge consumer response.

- Feedback Loops: Regularly collecting and analyzing consumer feedback can provide insights into how well your packaging resonates with different segments and what improvements can be made.

Challenges in Segment-Specific Customization

- Balancing Cost and Benefit: While customization can significantly increase appeal, it can also raise production costs. It’s crucial to balance the level of customization with the potential return on investment.

- Avoiding Stereotypes: It’s important to base customization on genuine consumer insights and avoid reinforcing stereotypes that might be offensive or outdated.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Customization for Different Segments: A Key Strategy in Packaging

A Half Slotted Container (HSC) is a specific type of corrugated box known for its robustness, versatility, and open-top design. These features make HSCs ideal

For businesses managing physical products, deciding between buying packaging materials in bulk and prioritizing storage space can be challenging. Both approaches have their merits and

In the world of packaging, there’s a rising star that has gained immense popularity – the Roll End Tuck Top (RETT) box. Its versatility, durability,