Home » Custom Packaging: Understanding Customer Buying Behavior

Custom Packaging: Understanding Customer Buying Behavior

In the competitive business landscape of today, custom packaging has emerged as a powerful tool to not only protect products but also make a lasting impression on customers. However, creating custom packaging that resonates with your target audience requires a deep understanding of their buying behavior. Customer buying behavior can be categorized into three main aspects: emotional, habitual, and rational. In this blog, we will explore how a company looking for custom packaging should consider these factors to design packaging that captivates and engages customers effectively.

Emotional Buying Behavior

Emotional buying behavior is deeply rooted in the customer’s feelings and desires. It revolves around the emotional connection a customer forms with a product or brand. When designing custom packaging with emotional buying behavior in mind, consider the following:

Brand Storytelling: Your packaging should tell a compelling story about your brand. Use colors, images, and text that evoke emotions associated with your product. For example, if your product is eco-friendly, use earthy tones and images of nature to connect with environmentally conscious customers emotionally.

Aesthetic Appeal: Visual aesthetics play a crucial role in emotional buying behavior. Ensure that your packaging design is visually appealing and aligns with your brand’s personality. If your brand is playful, use vibrant colors and whimsical designs. For a luxury brand, opt for minimalist, sophisticated packaging.

Personalization: Personalization can create a sense of exclusivity and connection. Consider adding personal touches like the customer’s name or a personalized thank-you note. This makes customers feel valued and appreciated.

Habitual Buying Behavior

Habitual buying behavior is characterized by routine purchases where customers buy the same products repeatedly. Packaging design can influence habitual buying behavior in several ways:

Consistency: Maintain a consistent packaging design to make it easily recognizable. This consistency reinforces the habit of purchasing your product. Ensure that the color scheme, logo placement, and overall design remain the same over time.

Packaging Practicality: Packaging should be practical and easy to open, ensuring a seamless experience for customers. If your packaging is too complicated, customers may switch to a more convenient option.

Iconic Elements: Incorporate iconic elements into your packaging design that become synonymous with your brand. Think of the iconic Coca-Cola bottle or the distinctive shape of a Toblerone chocolate bar. These elements trigger habitual buying behavior.

Rational Buying Behavior

Rational buying behavior is based on logic, practicality, and the customer’s evaluation of product features. To cater to customers with rational buying behavior, consider the following:

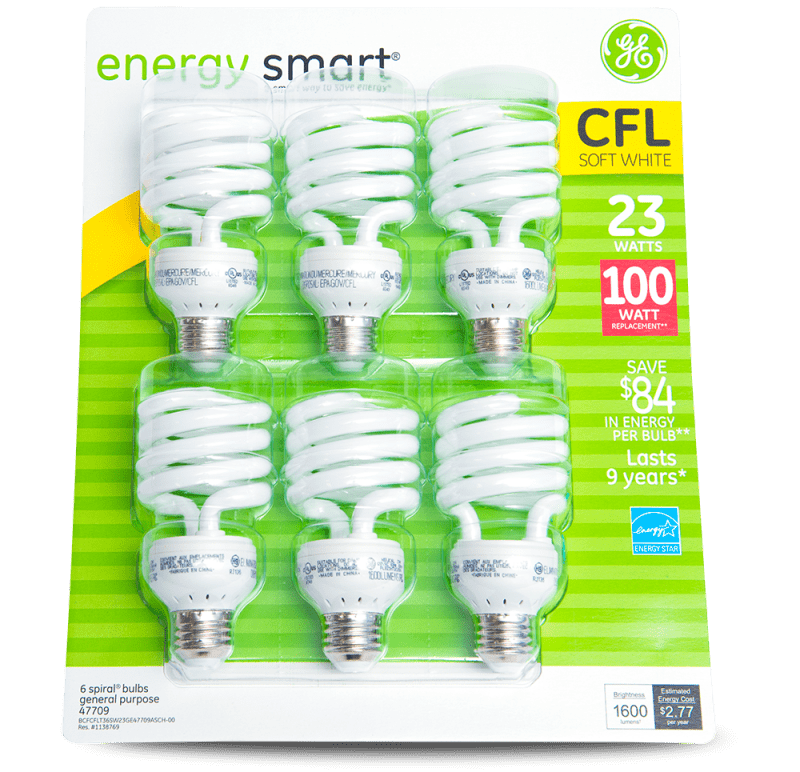

Information Clarity: Ensure that your packaging provides clear and concise information about the product. Include key details like ingredients, usage instructions, and benefits. Use easy-to-read fonts and organize information logically.

Eco-Friendliness: Today’s consumers are increasingly environmentally conscious. Consider using eco-friendly materials and clearly highlighting this on your packaging. Rational buyers often appreciate brands that align with their values.

Packaging Size and Functionality: Rational buyers assess packaging size and functionality. If your product is sold in various quantities or sizes, ensure the packaging accommodates these options efficiently. Avoid excessive waste in packaging materials.

If you are interested in custom packaging, then partner with Brown Packaging today to get started.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Home » Custom Packaging: Understanding Customer Buying Behavior

In the realm of packaging, the size and weight of a package are more than just physical dimensions; they are critical factors that influence a

Retail packaging must do two jobs at once—catch the shopper’s eye while protecting the product through the supply chain. Too much focus on graphics can

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to