Home » Corrugated POP Display Printing

Corrugated POP Display Printing

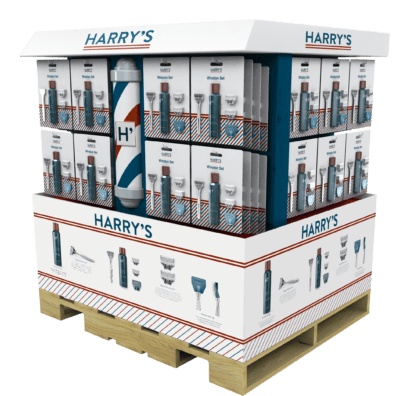

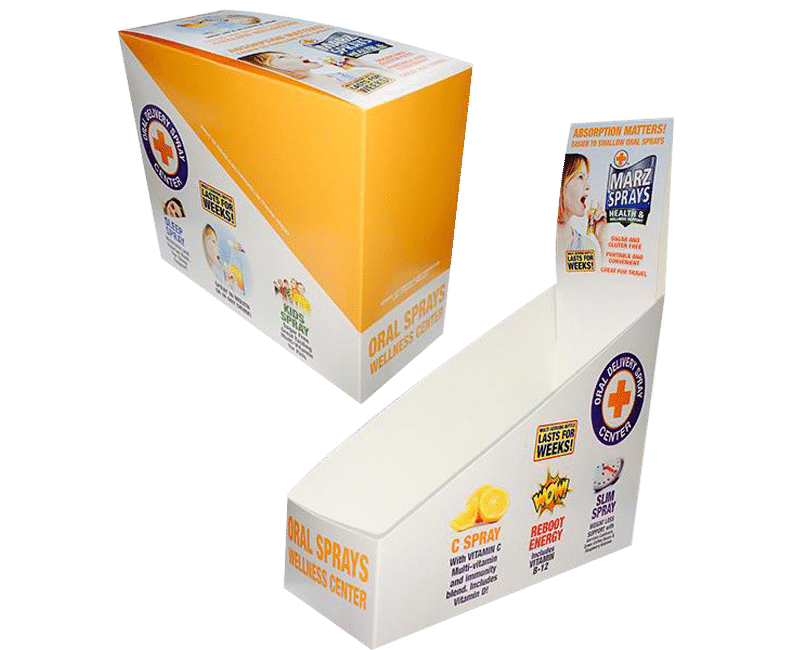

Point-of-purchase (POP) displays are designed to capture shopper attention and influence buying decisions. Beyond structure and branding, the quality of print determines how well a display communicates from multiple viewing angles in a retail environment. Selecting the right printing method ensures your display performs both visually and functionally.

Printing Methods for Corrugated POP Displays

Not all printing methods are suited for corrugated displays. Each has its own strengths and trade-offs in cost, speed, quality, and run size. The three most common methods are:

Flexographic Printing

Flexographic printing uses plates to apply ink as material passes through rollers.

Advantages

Cost-Efficient at Scale: Once plates are created, cost per unit is low for large or repeat orders.

Pantone Accurate: Ensures precise color matching across production runs.

Versatile: Works on uneven surfaces and a wide range of substrates.

High Speed: Suited for mass production.

Limitations

High Startup Costs: Plates and tooling are expensive, making short runs less economical.

Poor for Sampling: Costly and impractical to produce prototypes.

Best Fit: Large-volume retail displays where consistency and color accuracy are priorities.

Digital Printing

Digital printing applies artwork directly from a file to the substrate, eliminating plates.

Advantages

Low Startup Cost: Cost-effective for short runs and prototypes.

Fast Turnaround: Ideal for tight deadlines or seasonal campaigns.

Flexible: Easily handles multiple SKUs or frequent artwork changes.

High Quality: Produces sharp graphics suitable for branded displays.

Limitations

Less Economical at Scale: Higher cost per unit for large volumes.

Color Variability: Approx. 95% accurate; not a perfect Pantone match.

Slower Mass Output: Not as efficient as flexographic presses for high quantities.

Best Fit: Small-batch retail displays, prototypes, or variable-data campaigns.

Lithographic (Offset) Printing

Lithographic printing transfers ink from a plate to a rubber blanket, then onto the substrate, with options for coatings or varnishes.

Advantages

Highest Quality: Sharp, detailed graphics with accurate color reproduction.

Premium Finishes: Coatings and varnishes enhance durability and appearance.

Scalable: Handles small to large format prints.

Limitations

High Setup Cost: Plates and setup make short runs expensive.

Not Sample-Friendly: Prototypes are cost-prohibitive.

Longer Lead Time: Setup and adjustments require planning.

Best Fit: High-volume displays where premium image quality is essential for brand impact.`

Designing Graphics for POP Displays

Effective POP displays combine structure with clear, impactful graphics. Common elements include:

Logos and Brand Colors

Product Imagery

Text (ingredients, instructions, contact info)

Symbols and Icons

Promotions or Pricing

Call-to-Action Messaging

Mascots or Characters

Any artwork provided must be adjusted to fit dielines correctly. Designers ensure bleed, folds, and structural features align with graphics to avoid misprints.

Choosing the Right Printing Method

When selecting a printing process, consider:

Quality: Lithographic offers the highest resolution; flexographic is durable but less detailed.

Budget and Quantity: Flexographic suits large runs, digital works best for small runs, lithographic for high-volume premium graphics.

Lead Time: Digital is fastest due to no plate requirements.

Brand Goals: For premium retail impact, lithographic justifies higher cost; for efficiency, flexographic is the workhorse.

Buyer Takeaway

Use flexographic printing for large-scale runs that need durability and consistent Pantone colors.

Choose digital printing for prototypes, short runs, or campaigns with multiple SKUs.

Invest in lithographic printing for premium displays that require sharp, high-quality graphics.

Selecting the right method ensures POP displays not only stand out visually but also align with budget and timeline requirements.

References

Association of Independent Corrugated Converters (AICC). (2024). Printing Methods in Corrugated Packaging. Retrieved from https://www.aiccbox.org

Flexible Packaging Association. (2023). Digital vs. Flexographic Printing. Retrieved from https://www.flexpack.org

Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Corrugated POP Display Printing

The design and prototyping phase is a pivotal step in the creation of a Point of Purchase (POP) display. It’s where the conceptual groundwork laid

When it comes to retail marketing, Point of Purchase (POP) displays are essential for capturing customer attention and promoting your products effectively. The size and

In the dynamic world of retail, success is determined not only by the quality of products but also by the efficiency of their presentation and