Home » Corrugated Partition Inserts: Enhancing Box Functionality

Corrugated Partition Inserts: Enhancing Box Functionality

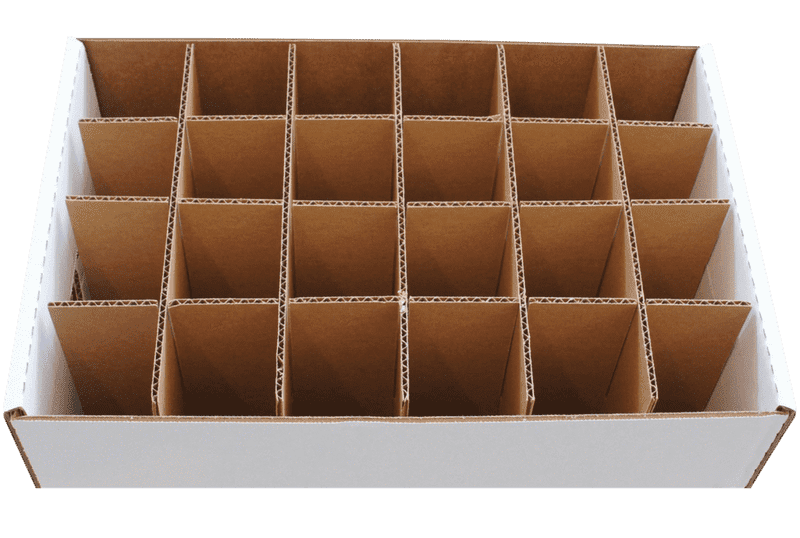

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard, a versatile and durable material widely used in the packaging industry. By incorporating partition inserts, boxes can be transformed into organized compartments, providing protection, support, and separation for the packaged items.

In this blog, we will explore the various benefits and applications of corrugated partition inserts, as well as their contribution to sustainable packaging solutions.

Benefits of Corrugated Partition Inserts

Protection and Stability

Corrugated partition inserts offer excellent protection for delicate or fragile items during transit. The inserts can be designed to fit snugly inside the box, creating individual compartments that prevent the packaged items from shifting or colliding with each other. This added stability minimizes the risk of damage and ensures that products arrive at their destination in optimal condition.

Improved Organization and Presentation

With corrugated partition inserts, boxes can be organized and segmented into multiple compartments, allowing for better item separation and organization. This is particularly beneficial for industries such as cosmetics, electronics, and food, where products need to be individually stored or displayed. The inserts also contribute to a visually appealing presentation, creating an attractive and professional appearance for the packaged items.

Enhanced Efficiency in Handling and Storage

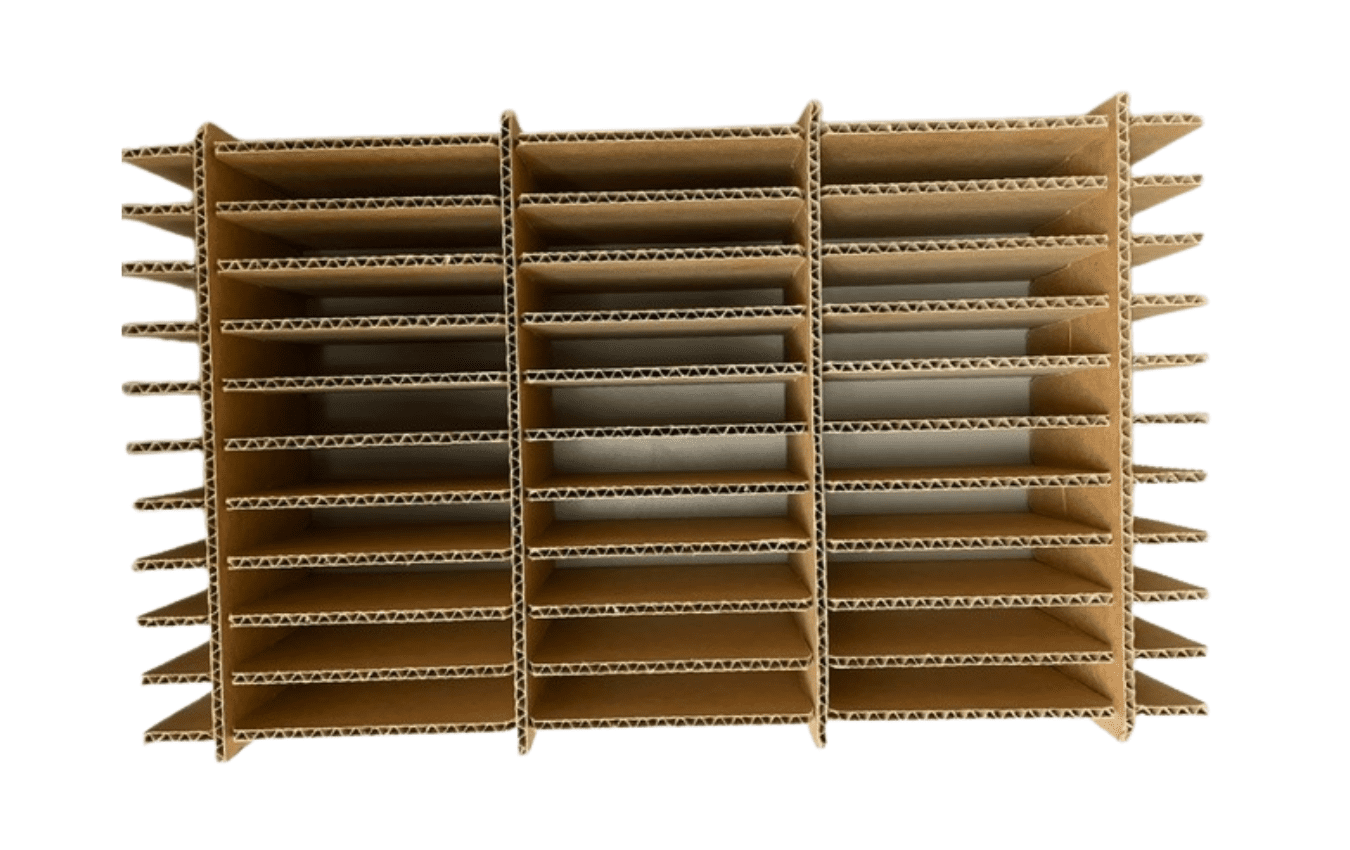

Partition inserts streamline the handling and storage process by simplifying the identification and retrieval of specific items. By providing separate compartments for each product, inserts eliminate the need for time-consuming searching or sorting through a box full of items. This increased efficiency can greatly benefit distribution centers, warehouses, and retail operations.

Customizability and Versatility

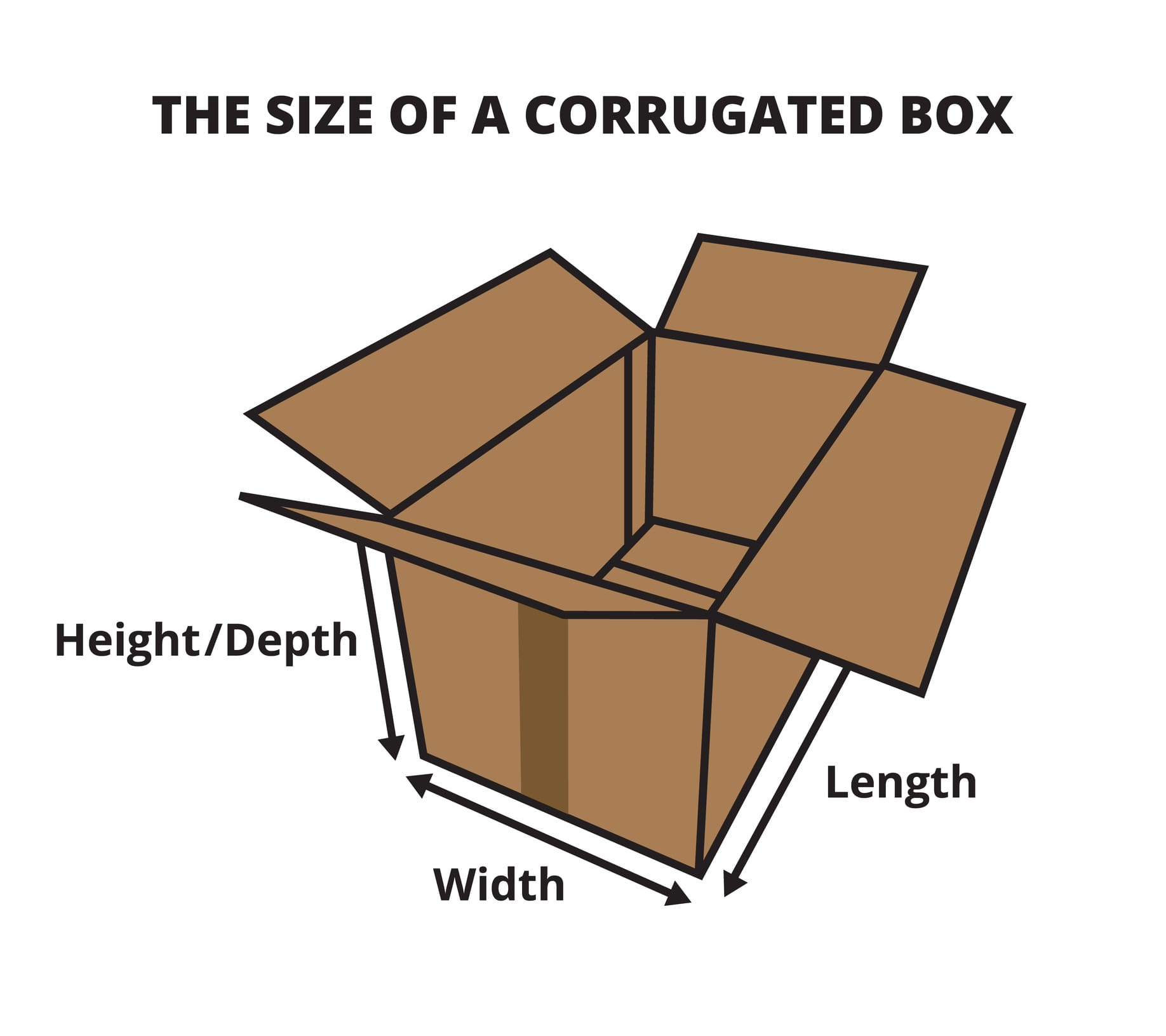

Corrugated partition inserts can be customized to fit the specific dimensions and requirements of various products. Manufacturers can design inserts with different cell sizes and configurations, allowing for optimal placement and protection of items with different shapes, sizes, and fragility levels. This versatility makes partition inserts suitable for a wide range of industries and product types.

Applications of Corrugated Partition Inserts

- Electronics and Technology: The electronics industry often deals with delicate components that require individual protection. Corrugated partition inserts can safeguard circuit boards, computer chips, and other electronic parts from damage during shipping. The inserts ensure that each component remains secure and isolated, reducing the risk of static discharge and other potential hazards.

- Pharmaceutical and Healthcare: In the pharmaceutical and healthcare sectors, the integrity and safety of products are paramount. Partition inserts can be utilized to separate and protect vials, syringes, medicine bottles, and other medical supplies. These inserts help prevent contamination, breakage, and the mixing of different substances, ensuring the quality and efficacy of pharmaceutical products.

- Food and Beverage: Corrugated partition inserts find applications in the food and beverage industry, particularly for the packaging of fragile or delicate food items. Inserts can keep items like glass bottles, jars, or delicate products secure and separate from one another, minimizing the chance of breakage or spoilage. Additionally, partitioned compartments can be used to package multiple items together, allowing for easy assembly of gift sets or sampler packs.

Sustainability and Corrugated Partition Inserts

Corrugated partition inserts contribute to sustainable packaging solutions in several ways:

Recyclability

Like corrugated cardboard boxes, partition inserts are recyclable and can be transformed into new paper products. By using recyclable materials, companies can reduce their environmental impact and support a circular economy.

Reduced Material Consumption

Partition inserts optimize the use of materials by providing individual compartments, eliminating the need for excessive cushioning or additional packaging. This reduces the overall material consumption and waste generation.

Lightweight and Space-Efficient

Corrugated cardboard partition inserts are lightweight, which helps reduce transportation costs and carbon emissions. Their space-efficient design allows for more products to be packed in a single shipment, maximizing the use of cargo space and minimizing the need for additional vehicles.

Biodegradability

Corrugated partition inserts are made from natural fibers, which means they are biodegradable. When disposed of properly, they break down naturally over time without releasing harmful pollutants into the environment.

Renewable Material Source

Corrugated cardboard is made from a renewable resource—trees. Responsible forestry practices ensure the sustainability of the raw materials used in the production of corrugated partition inserts, minimizing the impact on forests and promoting environmental stewardship.

Summary: Corrugated Partition Inserts

Corrugated partition inserts offer numerous benefits for packaging applications, ranging from enhanced protection and organization to improved efficiency and presentation. Their customizability and versatility make them suitable for a wide range of industries, including electronics, pharmaceuticals, and food and beverage.

Moreover, these inserts contribute to sustainable packaging solutions by being recyclable, lightweight, space-efficient, biodegradable, and sourced from renewable materials. By incorporating corrugated partition inserts into their packaging designs, companies can enhance the functionality of their boxes while minimizing their environmental footprint.

If you are interested in corrugated partitions or other types of inserts, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Corrugated Partition Inserts: Enhancing Box Functionality