Home » Comparing Single vs. Multi-Material Packaging

Comparing Single vs. Multi-Material Packaging

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026.

What Is Single-Material Packaging?

Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure.

Advantages:

- Easier to recycle and dispose.

- Lower material costs in many cases.

- Streamlined sourcing and inventory.

- Supports sustainability messaging.

Disadvantages:

- Limited barrier protection.

- Less customization for fragile or complex products.

May require added thickness for strength, increasing weight.

What Is Multi-Material Packaging?

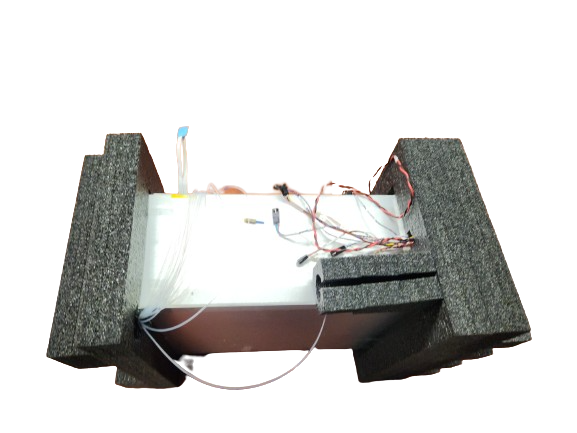

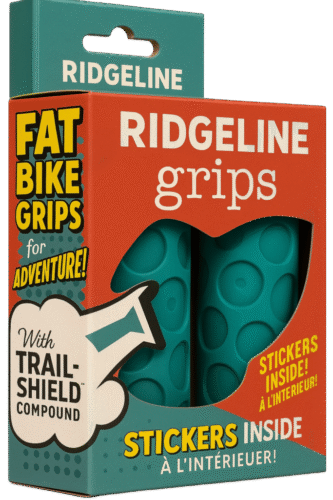

Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes.

Advantages:

- Greater protection against moisture, oxygen, and impact.

- Allows for premium finishes and enhanced graphics.

- Ideal for fragile or high-value products.

- Customizable for unique supply chain conditions.

Disadvantages:

- More difficult to recycle due to material separation.

- Higher cost and longer lead times.

- Complex sourcing and inventory management.

When to Use Each Approach

- Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs.

- Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection.

Balancing Performance and Sustainability

Buyers must weigh performance needs against eco goals:

- Use recyclable coatings to extend single-material performance.

- Choose hybrid designs that separate easily for recycling.

Apply multi-material solutions only where risk of damage outweighs cost.

Packaging Solutions with Brown Packaging

Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products.

References

Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.org

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Comparing Single vs. Multi-Material Packaging