Home » Choosing the Right Corrugated Packaging Board

Choosing the Right Corrugated Packaging Board

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and specifications available, it can be challenging to decide which is best suited for your products. This guide breaks down the key differences between board options, including thickness, weight, color (kraft vs. white vs. Kemi), and strength (stacking vs. bursting), to help you make informed choices.

Key Factors to Consider When Choosing Board Options

Thickness and Weight

- The thickness and weight of your board directly impact the durability and cost of your packaging.

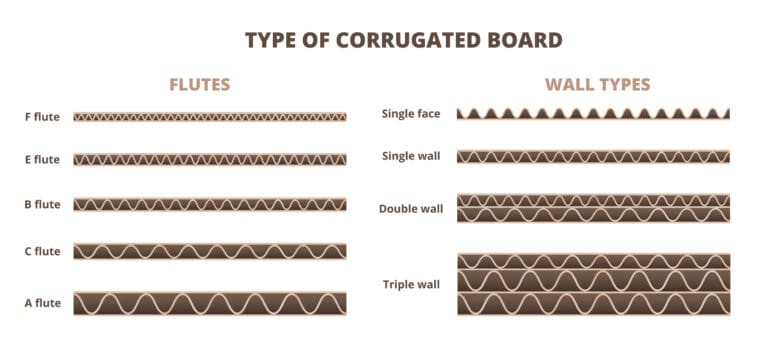

- Single-Wall Corrugated: Ideal for lightweight products; cost-effective and space-saving.

- Double-Wall Corrugated: Provides additional durability for heavier or more fragile items.

- Triple-Wall Corrugated: Offers maximum strength for industrial or bulk shipments.

Weight Classifications (measured in pounds per thousand square feet):

- 26 ECT (Edge Crush Test): Common for lightweight items.

- 32 ECT: Standard for shipping boxes.

- 44 ECT: Provides added strength for heavier goods.

Pro Tip: Higher ECT ratings or thicker boards are better for products requiring long shipping routes or frequent handling.

Kraft vs. White vs. Kemi

- The color and surface type of your board affect its appearance, branding potential, and environmental impact.

- Kraft Board:

- Natural, unbleached brown board.

- Eco-friendly and cost-effective.

- Popular for brands emphasizing sustainability.

- White Board:

- Provides a clean, polished look.

- Ideal for high-quality printing and branding.

- Slightly higher cost due to added processing.

- Kemi Board:

- A premium option with a clay-coated surface.

- Superior for high-quality graphics and moisture resistance.

- Often used in food packaging or high-end retail boxes.

Pro Tip: Kraft is a great choice for eco-conscious brands, while white or Kemi boards work best for visually appealing, printed designs.

Stacking Strength vs. Bursting Strength

Board strength is measured in two key ways, and understanding the difference is crucial for selecting the right material for your needs.

- Stacking Strength (Edge Crush Test – ECT):

- Measures a box’s ability to withstand compression when stacked.

- Ideal for vertical storage or heavy stacking in transit.

- Bursting Strength (Mullen Test):

- Measures resistance to punctures or tears.

- Better for products that might face rough handling or impact during shipping.

Pro Tip: If you’re shipping lightweight items in large quantities, prioritize stacking strength. For fragile or high-value items, bursting strength is more critical.

Comparing Board Options

Feature | Single-Wall Corrugated | Double-Wall Corrugated | Triple-Wall Corrugated |

Thickness | Light | Medium | Heavy |

Weight Capacity | Up to 65 lbs | 65–95 lbs | 95–300 lbs |

Common Use Cases | Apparel, lightweight items | Electronics, fragile goods | Industrial equipment, bulk items |

Cost | Low | Medium | High |

Selecting the Right Board for Your Needs

- Product Protection Needs

- For lightweight products: Single-wall corrugated with 32 ECT.

- For heavy or fragile items: Double-wall corrugated or higher ECT.

- For high-value items: Triple-wall corrugated or Kemi board with enhanced burst strength.

- Branding and Visual Appeal

- For a natural look: Kraft board.

- For premium branding: White or Kemi boards with gloss or matte finishes.

- Environmental Considerations

- For eco-conscious brands: Kraft board with recycled content.

- For durability with sustainability: Boards with high post-consumer recycled content.

FAQs About Board Options

Stacking strength measures a box’s ability to withstand vertical pressure, while bursting strength evaluates its resistance to punctures or tears.

When should I choose Kemi over white or kraft?

Kemi board is ideal for applications requiring superior graphics and moisture resistance, such as food or luxury packaging.

How do I balance cost and durability?

Consider your product’s weight and shipping needs. Single-wall corrugated is cost-effective for lightweight items, while double-wall is better for heavier goods.

Conclusion

Choosing the right board option involves balancing your product’s protection needs, branding goals, and budget. Whether you’re deciding between kraft and white or evaluating strength requirements, understanding these factors will help you select the perfect packaging solution.

Need expert advice on board materials?

Contact us today for tailored recommendations that meet your durability, branding, and budget goals!

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers predict failures, validate material changes,

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » Choosing the Right Corrugated Packaging Board