Home » Choosing the Right Corrugated Grade for 2026

Choosing the Right Corrugated Grade for 2026

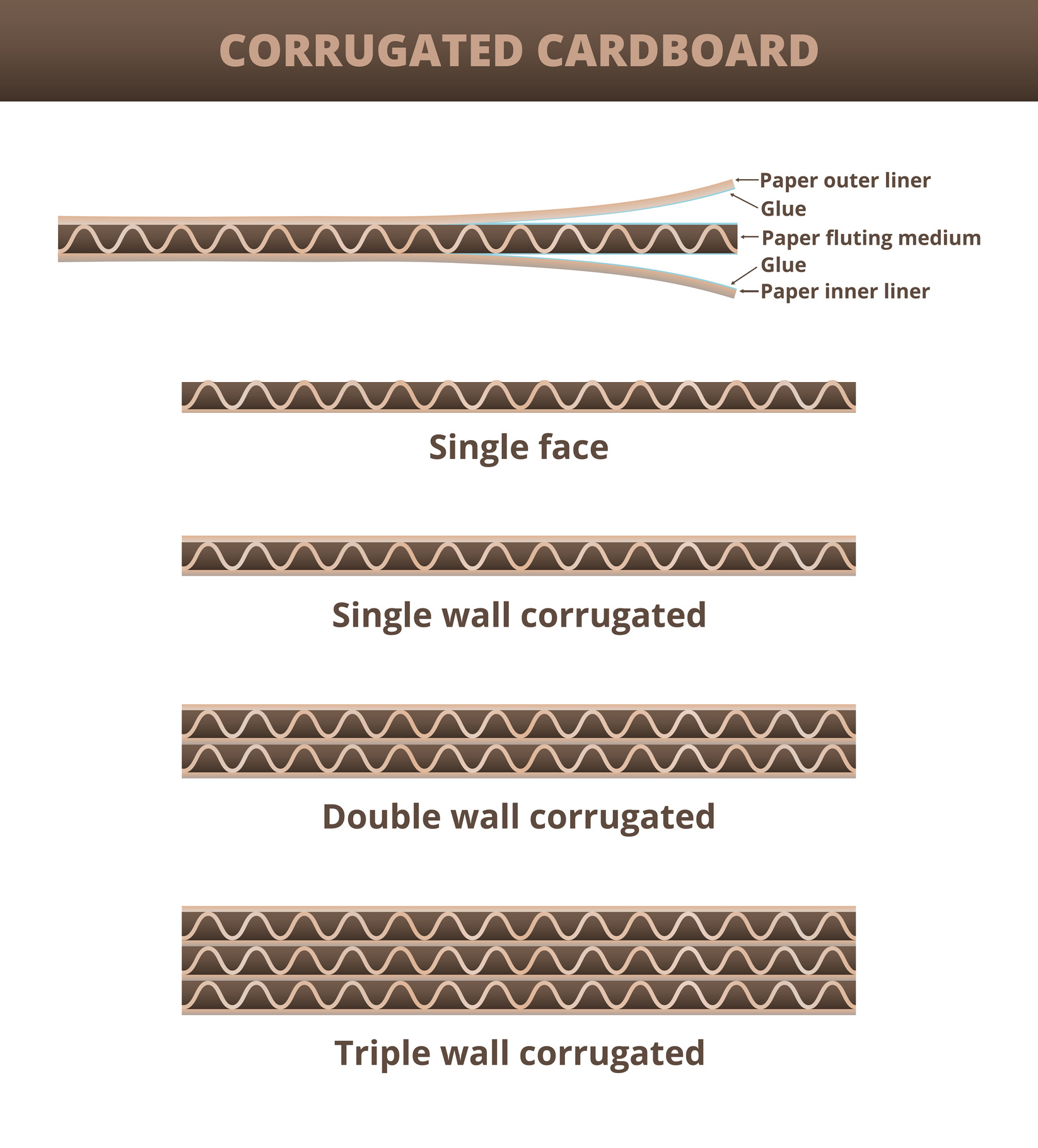

Corrugated board comes in multiple flute sizes and wall grades, each designed to balance strength, weight, and cost. Selecting the wrong grade can lead to product damage, excessive freight costs, or unnecessary material expense. In 2026, buyers must match corrugated performance to their supply chain conditions, sustainability goals, and budget requirements.

Common Corrugated Grades

- Single-wall: Lightweight, cost-effective, suitable for many retail and e-commerce uses.

- Double-wall: Greater strength and stacking ability for heavy or fragile items.

- Triple-wall: Maximum compression resistance for industrial, bulk, and export packaging.

Key Factors When Choosing a Grade

- Product weight: Heavier items require stronger board.

- Supply chain conditions: Long transit times, stacking, and climate variations increase stress.

- Cost balance: Higher grades protect better but add material expense.

- Sustainability goals: Use recycled content or right-size to minimize waste.

- Compliance: Certain industries require ISTA or ASTM-tested packaging.

How to Match Grade to Application

- E-commerce: Single-wall RSCs with performance coatings for moisture resistance.

- Industrial parts: Double-wall or triple-wall for high stacking and pallet loads.

- Export packaging: Triple-wall FOL boxes for international freight durability.

- Retail displays: Lighter grades with strong print surfaces for shelf appeal.

Testing for Performance Confidence

- Compression testing: Ensures cartons withstand stacking loads.

- Vibration and drop testing: Validates protection during transport.

- Material analysis: Confirms recycled fiber content aligns with performance goals.

Packaging Solutions with Brown Packaging

Brown Packaging works with buyers to identify the right corrugated grade for each application. From single-wall e-commerce boxes to triple-wall export packaging, we balance protection, cost, and sustainability. Contact us to select the right grade for 2026.

References

ASTM International. (2023). ASTM D642: Standard Test Method for Compression Resistance of Shipping Containers.

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

Fiber Box Association. (2024). Corrugated Packaging Performance Handbook. Retrieved from https://www.fibrebox.org

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Choosing the Right Corrugated Grade for 2026