Home » California’s Push Against Single-Use Plastics: Impact on Packaging

California’s Push Against Single-Use Plastics: Impact on Packaging

In the ongoing battle against environmental degradation, California has emerged as a leader in the fight to reduce single-use plastics. With a series of comprehensive laws and regulations, the Golden State has taken bold steps to curb the use of these harmful materials. Bans on single-use plastic bags, straws, and expanded polystyrene (Styrofoam) food containers are just a few examples of California’s commitment to a greener future. In this blog, we’ll explore these regulations and their significant implications for packaging choices, particularly within the food and beverage industry.

California’s Stringent Regulations on Single-Use Plastics

California’s proactive stance on reducing single-use plastics has resulted in several impactful regulations:

Ban on Single-Use Plastic Bags:

In 2014, California became the first state in the U.S. to ban single-use plastic bags at most retail stores. This groundbreaking law aimed to reduce plastic pollution, encourage reusable bag usage, and promote sustainability.

Straws on Request:

Under the “Straws on Request” law that took effect in 2019, restaurants in California can only provide plastic straws upon customer request. This measure significantly reduces the distribution of single-use plastic straws, minimizing plastic waste.

Ban on Expanded Polystyrene (Styrofoam) Food Containers:

California implemented a ban on expanded polystyrene (EPS) foam food containers in 2020. The use of EPS for takeout containers, cups, and plates is now prohibited due to its environmental impact and persistence in the environment.

The California Circular Economy and Plastic Pollution Reduction Act:

Enacted in 2020, this law sets ambitious targets for reducing plastic waste and increasing recycling rates in California. It encourages manufacturers to use more recycled materials in their products and promotes a circular economy for plastics.

Implications for Packaging Choices in the Food and Beverage Industry

California’s stringent regulations on single-use plastics have far-reaching implications for businesses, particularly those in the food and beverage industry:

Adoption of Sustainable Alternatives:

With bans on EPS foam containers, businesses must seek sustainable alternatives for packaging. This shift has led to the adoption of compostable or recyclable materials, such as paper-based packaging, reusable containers, and innovative eco-friendly materials.

Emphasis on Reusability:

The ban on single-use plastic bags and straws has placed a renewed emphasis on reusable packaging options. Restaurants and food establishments are increasingly offering reusable containers and encouraging customers to bring their own bags and containers.

Focus on Eco-Friendly Packaging Designs:

As businesses seek to comply with California’s regulations, they are investing in packaging designs that are both functional and environmentally responsible. This includes using materials that are easily recyclable or compostable and reducing excessive packaging.

Consumer Awareness and Preference:

California consumers are becoming more aware of environmental issues, leading to a preference for businesses that embrace sustainable packaging practices. Packaging choices that align with these preferences can be a competitive advantage.

If you are interested in packaging solutions in California, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » California’s Push Against Single-Use Plastics: Impact on Packaging

As we gear up for 2024, the world continues to evolve and adapt to the ever-growing demands of sustainability. A major focal point of this

As the world becomes more environmentally conscious, companies are looking for ways to reduce their impact on the planet. One of the ways that they

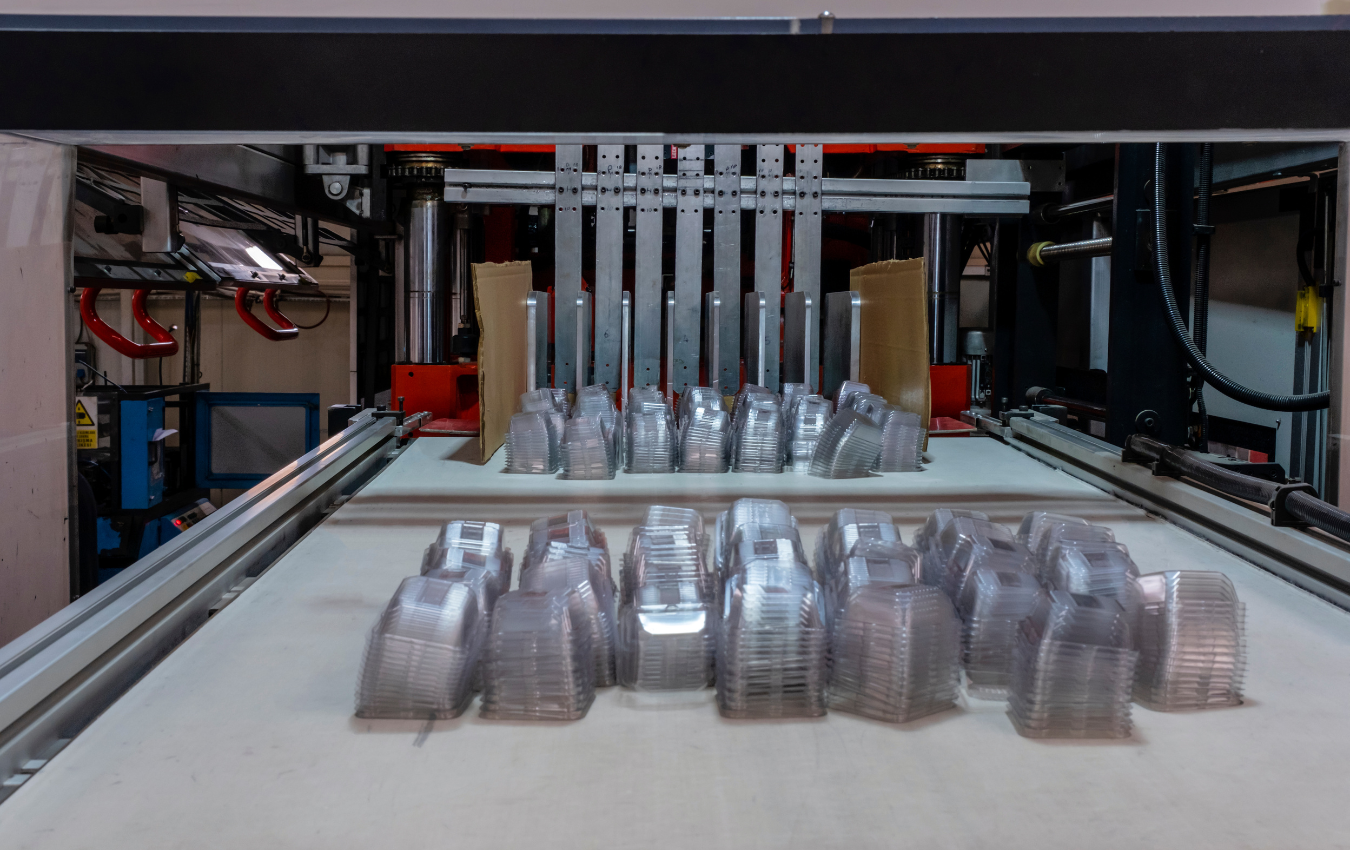

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability