Home » Blister Packs Vs Clamshells: Which Should You Choose?

Blister Packs Vs Clamshells: Which Should You Choose?

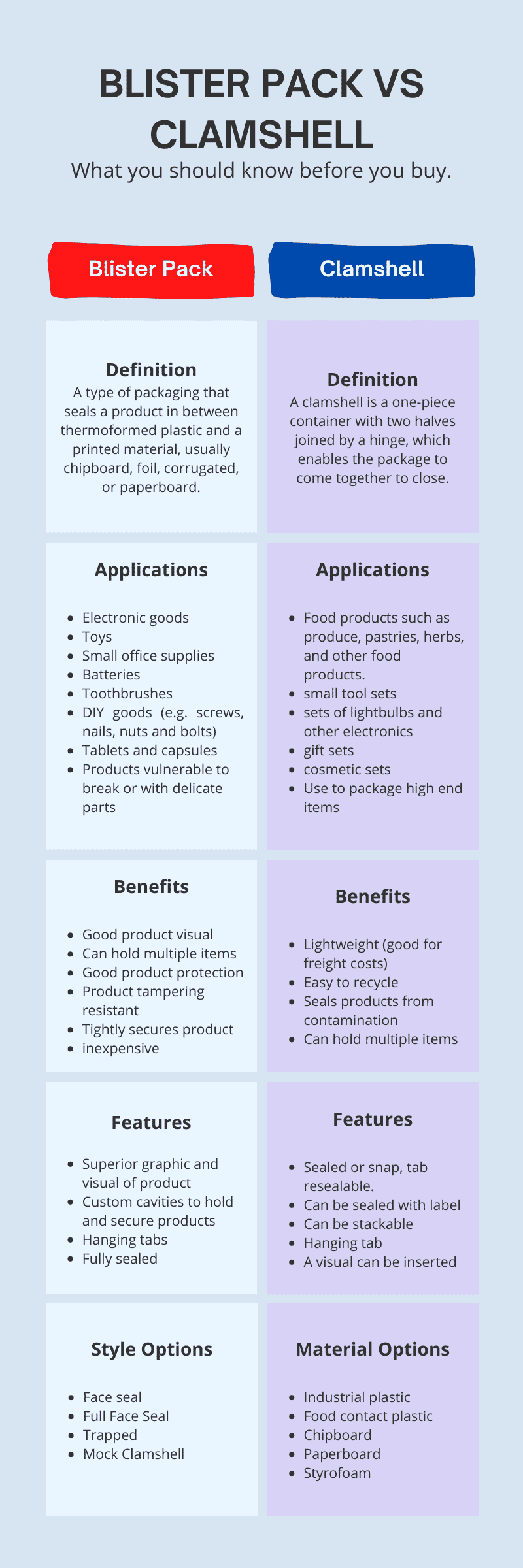

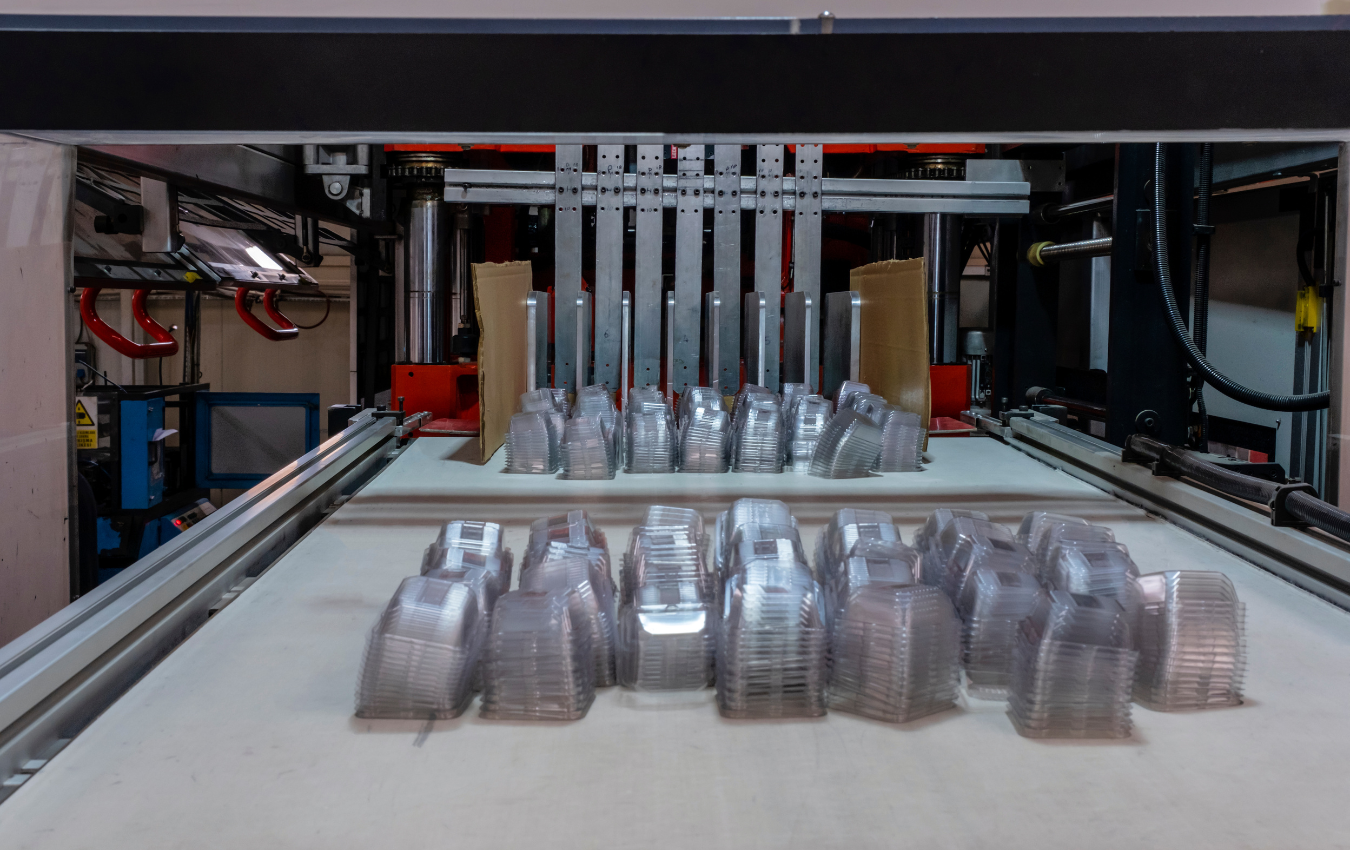

When it comes to product packaging, choosing between blister packaging and clamshell packaging can often be confusing, as they both originate from the thermoforming process and can appear quite similar on retail shelves. However, each has distinct features and benefits, making it crucial to understand their differences to make an informed decision that aligns with your product needs and packaging goals.

Understanding Blister Packs and Clamshells

What is a Blister Pack?

Blister packs are predominantly used to encase products within a pre-formed plastic cavity, sealed against a backing material such as paperboard, foil, or plastic. This packaging is favored for its robustness and ability to clearly display the product.

Features of Blister Packs

- Custom Cavities: Tailored to snugly fit the product, ensuring it remains securely in place.

- Hanging Tabs: Often included for easy retail display.

- Sealing Options: Can be heat-sealed or cold-sealed, enhancing tamper resistance.

- Material Versatility: Available in various materials including PET, HDPE, PP, and PVC.

- Graphic Customization: Allows for the addition of logos, branding, and product information directly on the backing.

Advantages of Blister Packaging

- Product Visibility: Provides clear visibility of the product, enhancing buyer appeal.

- Tamper Evident: The sealing process helps prevent tampering and ensures product integrity.

- Cost-Efficiency: Generally less expensive on a per-unit basis, especially suitable for high-volume products.

- Consumer Trust: Consumers can view the product without opening the packaging, increasing trust and reducing the decision-making time.

Applications of Blister Packs

- Pharmaceuticals: Ideal for tablets, capsules, and other medications.

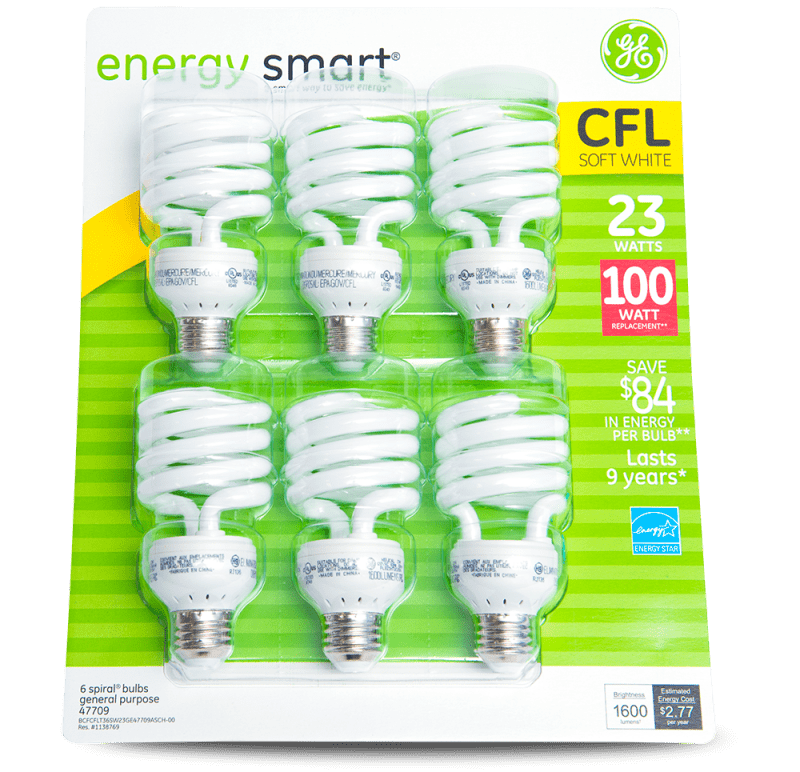

- Electronics: Protects components like batteries, earbuds, and cables.

- Consumer Goods: Suitable for small items such as toys, hardware accessories, and cosmetics.

Clamshells

Clamshell packaging consists of a single piece of thermoform plastic that hinges together to enclose the product completely. This type of packaging is resealable and provides a robust shield against external factors.

Features of Clamshells

- Snap Closures: Allows for the packaging to be securely closed and easily reopened.

- Stackability: Designed to be stacked for efficient transport and display.

- Visibility Inserts: Accommodates inserts for additional product information and branding.

- Material Flexibility: Made from a variety of plastics such as PET, HDPE, PP, and even more sustainable options like paperboard or bioplastics.

Advantages of Clamshell Packaging

- Enhanced Protection: Offers superior protection from crushing and puncturing, ideal for delicate items.

- Versatility: Can be designed to fit a wide range of product shapes and sizes.

- Consumer Convenience: Easy to open and reseal, enhancing user satisfaction.

- Brand Presentation: Offers ample space for branding and is highly customizable to fit marketing needs.

Applications of Clamshells

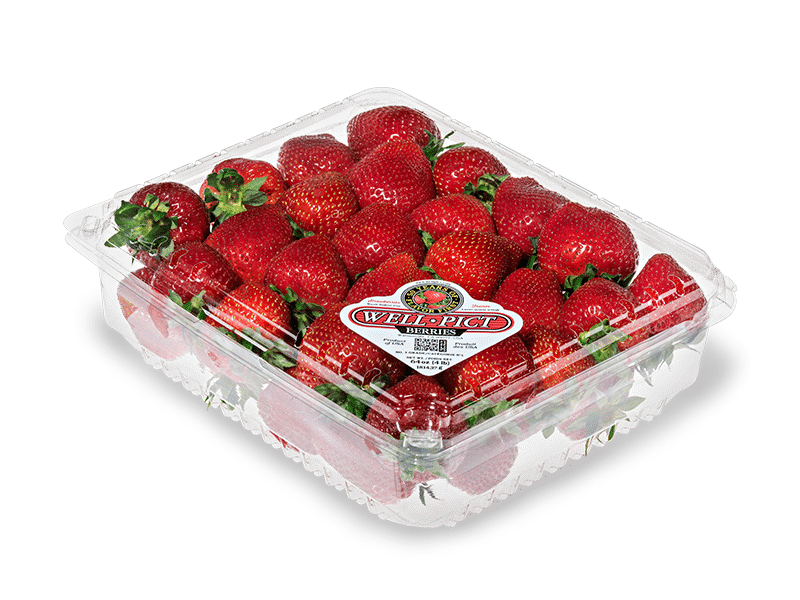

- Food Industry: Commonly used for fruits, salads, and bakery items.

- Retail Products: Effective for multi-component products or gift sets.

- Electronics: Provides a secure environment for gadgets, ensuring they remain free from damage.

Which Should You Choose?

The choice between blister packs and clamshells should be based on specific product requirements, customer handling expectations, and marketing objectives:

- Consider Blister Packs if: You need cost-effective packaging for high-volume products where visibility and tamper resistance are key.

- Opt for Clamshells if: Your product requires robust protection, especially if it’s high-value or delicate, and you want to enhance the consumer unboxing experience.

Both packaging types can be tailored to meet the specific needs of your products, and choosing the right type can significantly impact your product’s market success.

Understanding the unique properties of blister packs and clamshells is crucial for selecting the right packaging solution. Each has its own set of features, advantages, and suitable applications that can align with different product types and business goals. For expert guidance and custom packaging solutions that fit your needs, consider partnering with a specialized provider like Brown Packaging.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Blister Packs Vs Clamshells: Which Should You Choose?

In our daily lives, we come across a plethora of pharmaceutical products, either in our personal capacity or via someone close to us. In this

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability

Polypropylene, often referred to as PP plastic, is the second most widely used plastic globally, praised for its remarkable durability, strength, and resistance to various