Home » Best Practices in Protective Packaging for Fragile Items

Best Practices in Protective Packaging for Fragile Items

When it comes to shipping or storing fragile items, ensuring their safe arrival without any damage is of utmost importance. Fragile items such as glassware, electronics, ceramics, and artwork require special attention and protection during transportation. This blog aims to highlight the best practices in protective packaging for fragile items, offering valuable insights to individuals and businesses to ensure their delicate items reach their destination intact.

Understanding the Fragility of the Item

Before choosing the appropriate protective packaging, it is crucial to understand the fragility of the item. Assess its susceptibility to impact, vibration, compression, and temperature variations. This understanding will help determine the level of protection required and guide the selection of suitable packaging materials.

Selecting the Right Packaging Materials

Cushioning Materials

Bubble wrap, foam sheets, packing peanuts, and air pillows are popular cushioning materials. They provide a protective layer around the item, absorbing shocks and preventing direct contact with the outer packaging.

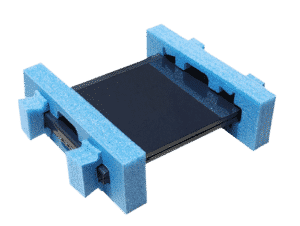

Inner Packaging

For fragile items with intricate details or multiple components, it is advisable to use inner packaging to provide additional protection. Custom foam inserts, cardboard dividers, and molded pulp trays can be tailored to fit the specific shape and size of the item, securing it in place and minimizing movement during transit.

Outer Packaging

The outer packaging should be sturdy and durable to withstand external impacts. Corrugated cardboard boxes are commonly used due to their strength and shock-absorbing capabilities. Reinforced corners or double-walled boxes provide extra protection.

Proper Packing Techniques

Wrap The Item

Start by wrapping the fragile item with a layer of bubble wrap or foam sheets, ensuring all sides are covered. Secure the wrapping with tape, but avoid applying tape directly to the item’s surface to prevent damage upon removal.

Fill Void Spaces

Fill the empty spaces within the box using packing peanuts, crumpled paper, or air pillows. This prevents the item from shifting or moving during transportation.

Labeling and Instructions

Clearly label the package as “Fragile” or “Handle with Care” to alert handlers and carriers of the delicate contents. Include any specific handling instructions, such as “This Side Up” or “Do Not Stack.”

Consider Specialized Packaging

Certain fragile items may require specialized packaging solutions tailored to their unique characteristics:

Temperature-sensitive items: For items sensitive to temperature fluctuations, consider insulated packaging or temperature-controlled containers.

Liquid or breakable items: Use leak-proof and sturdy containers, and seal them properly to prevent spills or breakage.

Artwork or delicate objects: Consider custom-built wooden crates or reinforced cardboard boxes designed specifically for protecting artwork and delicate objects. These containers provide added protection against impact, humidity, and temperature changes.

Partner with a Reliable Shipping Carrier

Choosing a reputable shipping carrier with experience in handling fragile items is crucial. Research carriers that offer specialized fragile item handling services or use dedicated fragile item shipping services. Insurance options are also worth considering to provide financial protection in case of damage during transit.

Final Thoughts: Protective Packaging and Fragile Items

Protective packaging plays a vital role in safeguarding fragile items during shipping or storage. By understanding the fragility of the item, selecting appropriate packaging materials, utilizing proper packing techniques, and considering specialized packaging, individuals and businesses can ensure the safe arrival of delicate items. Partnering with a reliable shipping carrier further enhances the chances of a successful and damage-free transportation experience.

Successful Examples of Creative Yet Functional Packaging

Many brands have successfully achieved this balance. Here are a few noteworthy examples:

Nike’s Air Max 95 Box: Nike designed a shoebox for the Air Max 95 that resembled the shoe’s design. Not only did it create a unique unboxing experience, but the box was sturdy and protective, maintaining the fundamental functionality of shoe packaging.

Puma’s Clever Little Bag: Puma replaced traditional shoe boxes with a reusable bag in a carton frame, reducing corrugated usage by 65%. This design retained its protective function while adding the creative element of a reusable bag for the customers, effectively telling a story about Puma’s commitment to sustainability.

Fit Buns High Protein Bread: This brand used packaging that features a muscular arm graphic which also serves as a handle. It’s a playful touch that reinforces the product’s high-protein, healthy angle, while providing functionality in the form of an easy-to-carry package.

In conclusion, the perfect blend of creativity and functionality in custom packaging can create a memorable brand experience, drive customer engagement, and ultimately fuel business growth. Striking this balance requires thoughtful design, innovative use of materials, rigorous testing, and a deep understanding of the customer’s journey. With the right approach, your packaging can serve as a powerful marketing tool that encapsulates your brand’s identity while serving its protective and informative roles impeccably.

In the realm of custom packaging, it’s all about creating harmony between the practical and the creative, turning each package into a canvas that tells your brand’s story and a protective shell that ensures your product reaches your customer in pristine condition. The interplay between these elements can result in a packaging design that is as enchanting as it is effective, delighting your customers and setting your brand apart in the marketplace.

If you are interested in custom packaging with a balance of functionality and creativity, then partner with Brown Packaging today.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Best Practices in Protective Packaging for Fragile Items

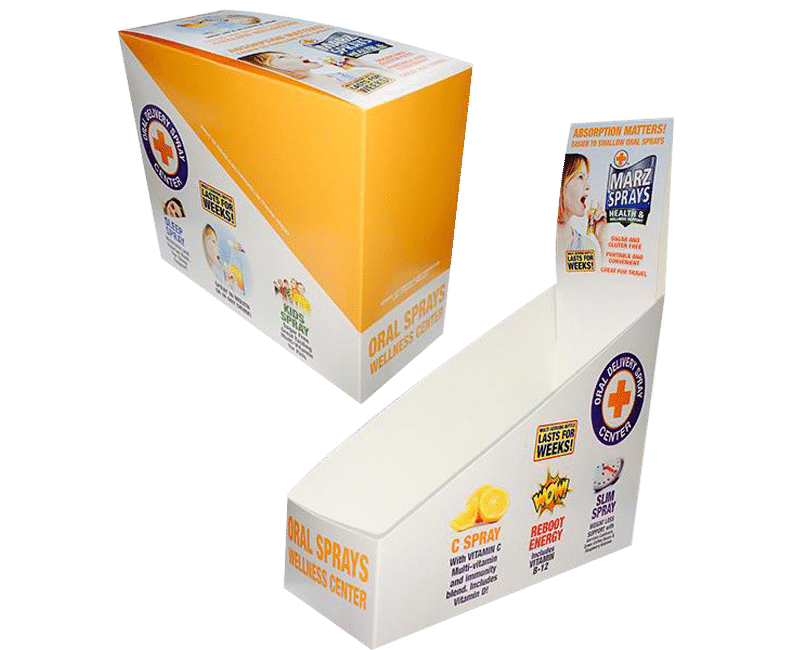

The design and prototyping phase is a pivotal step in the creation of a Point of Purchase (POP) display. It’s where the conceptual groundwork laid

As companies evaluate their packaging supply chains, many are choosing U.S. packaging suppliers over overseas alternatives. While domestic suppliers offer advantages such as faster lead

Rising tariffs and trade restrictions on Chinese manufacturing are accelerating the need for U.S. companies to reevaluate their packaging supply chains. Many packaging buyers who