Home » Auto Bottom vs. Tuck End Folding Cartons

Auto Bottom vs. Tuck End Folding Cartons

In the packaging industry, the design of a carton can significantly impact both the presentation and functionality of a product. Among the various styles available, auto bottom and tuck end folding cartons are popular choices, each with its distinct advantages. This blog post explores when to use an auto bottom carton versus a tuck end (straight or reverse) folding carton, helping you make an informed decision based on your product’s specific needs.

Understanding Auto Bottom Folding Cartons

Auto bottom cartons are designed for ease of assembly and durability. They feature a pre-glued bottom that automatically snaps into place when the carton is opened.

- Ease of Assembly: Ideal for efficiency in packing processes, as they can be quickly and easily assembled.

- Durability and Strength: The auto bottom design provides a strong and stable base, making these cartons suitable for heavier items.

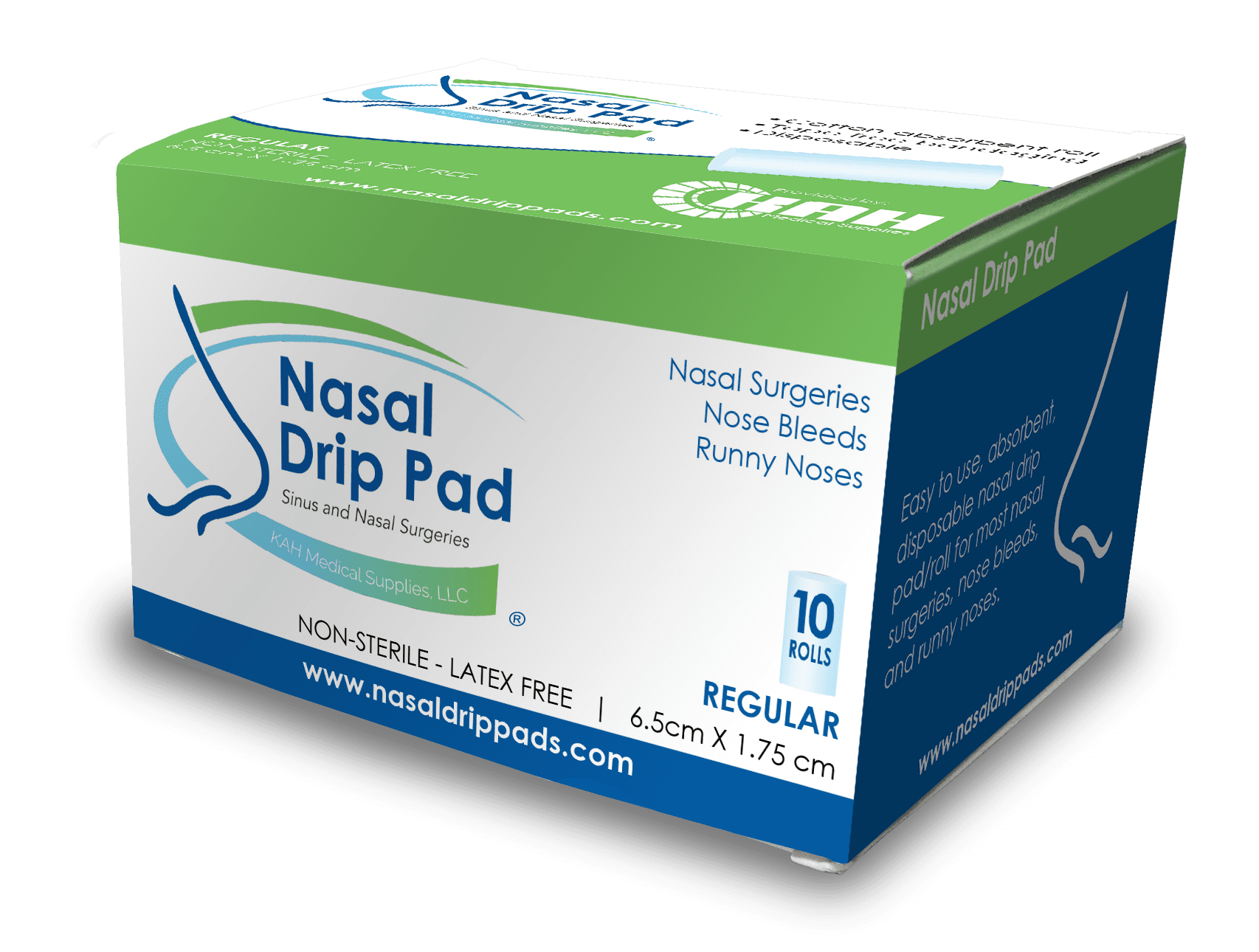

- Applications: Commonly used for products like cereals, frozen foods, and electronics that require sturdy packaging.

Exploring Tuck End Folding Cartons

Tuck end cartons come in two main types: straight tuck end and reverse tuck end. Both involve tucking flaps at one or both ends of the carton, but they differ in the direction in which the flaps close.

- Straight Tuck End:

- Flaps tuck in the same direction, providing a clean, uniform look.

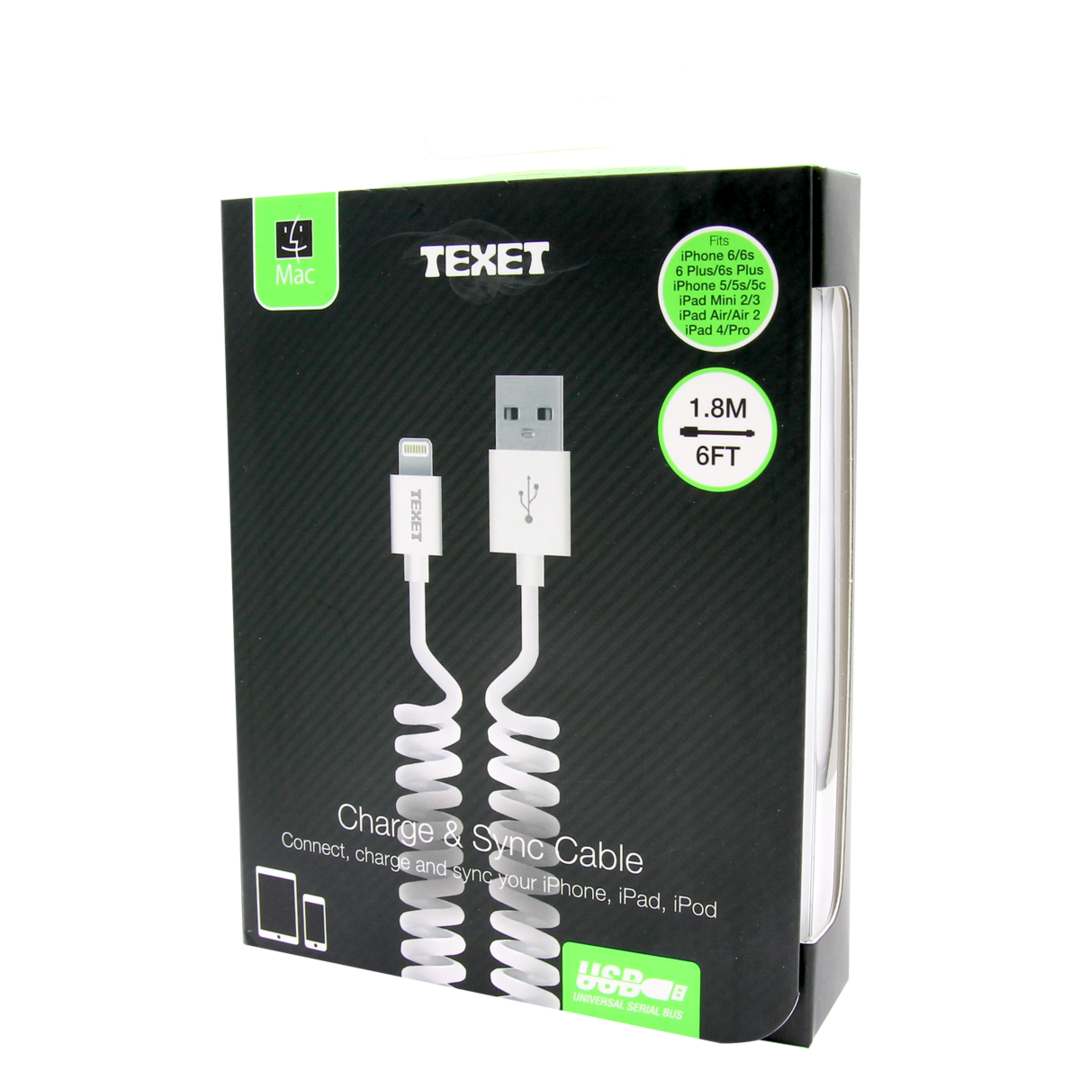

- Ideal for products where presentation is key, such as cosmetics or pharmaceuticals.

- The continuous surface is excellent for showcasing branding and product information.

- Reverse Tuck End:

- Flaps tuck in opposite directions, offering a secure closure.

- More stable when standing up than straight tuck end.

- Commonly used for lighter items, including consumer goods and food products.

When to Use Auto Bottom Cartons

Auto bottom cartons are particularly useful in the following scenarios:

- For Heavier Products: Their structural integrity makes them ideal for heavier items that require additional support at the base.

- High-Speed Assembly Requirements: If your packing process demands speed and efficiency, auto bottom cartons are a time-saver.

- Automated Packing Lines: They are well-suited for automated packaging systems, reducing manual labor and increasing productivity.

When to Opt for Tuck End Cartons

Tuck end cartons are preferred in situations where:

- Aesthetics Matter: If your product requires a high level of shelf appeal, straight tuck end cartons offer a sleek and clean presentation.

- Versatility in Packaging: Both straight and reverse tuck end cartons can accommodate a variety of products and are easily customizable in terms of size and design.

- Cost-Effectiveness: Particularly with reverse tuck end cartons, they can be more economical, making them suitable for products with tight budget constraints.

Customization and Branding

Both auto bottom and tuck end cartons offer excellent opportunities for customization and branding.

- Printing and Finishing Options: You can enhance the cartons with various printing techniques, finishes, and textures to make your product stand out.

- Sustainability Options: Consider eco-friendly materials and inks to appeal to environmentally conscious consumers.

If you are interested in custom folding cartons such as auto bottom, straight tuck end, reverse tuck end, or any other style, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Auto Bottom vs. Tuck End Folding Cartons

Folding cartons are one of the most versatile forms of retail packaging—and how you print on them can make the difference between a product that

E-commerce exposes folding cartons to more handling points, longer transit times, and harsher mechanical stresses than traditional retail distribution. Designing for these conditions requires careful

Folding cartons are a retail packaging staple—used across food, cosmetics, health, and consumer goods for their lightweight, customizable, and cost-effective structure. But not all folding