Home » Direct Thermal vs Thermal Transfer Printing: What is the Difference?

Direct Thermal vs Thermal Transfer Printing: What is the Difference?

Direct Thermal Printing

Direct thermal printing uses heat-sensitive media that darkens as it passes under a printhead. Because it does not require ink, toner, or ribbons, the process is both simple and low-maintenance.

Advantages:

Produces sharp, scannable barcodes and text.

Easy to operate with no consumables.

Offers sustainable options and low upkeep.

In addition, it requires no setup time.

Disadvantages:

However, labels are sensitive to light, abrasion, and heat.

They are not ideal for long-term use, often fading in 6–12 months.

As a result, protective coatings are sometimes needed.

Applications:

Direct thermal is best for short- to medium-term labels. For example, it is often used for shipping labels, visitor passes, meat carton tags, and receipts. On the other hand, it is not recommended for product barcodes that must endure a complex supply chain.

Direct Thermal Mobile Printer

Direct Thermal Printed Label

Thermal Transfer Printing

Thermal transfer printing uses a ribbon heated by the printhead, transferring ink directly into the label substrate. This process delivers long-lasting and durable labels that resist environmental stress.

Advantages:

Crisp, high-definition prints, long shelf life, supports 1D/2D barcodes, withstands moisture, UV, chemicals, and sterilization.

Disadvantages:

Higher cost, requires ribbons and setup, less sustainable, potential ribbon wrinkles.

Applications:

Product identification, inventory management, certification labels, circuit boards, laboratory specimens, cold storage, outdoor labeling, and industrial hazard identification.

Thermal transfer is ideal for long-term or critical labeling, where durability and resistance are essential.

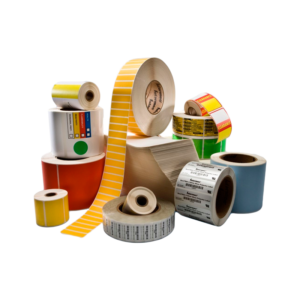

Thermal Transfer Labels

Thermal Transfer Label Printer

Choosing the Right Labeling Method

Use direct thermal for simplicity, cost efficiency, and short-life labels.

Use thermal transfer for durability, compliance, and high-performance labeling in demanding environments.

Label Solutions with Brown Packaging

From direct thermal shipping labels to long-lasting thermal transfer identification, Brown Packaging provides tailored labeling solutions for industrial, retail, and ecommerce operations. Contact us to find the right label system for your supply chain.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

GS1. (2023). Barcode Standards and Printing Guidelines. Retrieved from https://www.gs1.org

FSC. (2023). Responsible Labeling in Packaging. Forest Stewardship Council.

Meta description:

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Direct Thermal vs Thermal Transfer Printing: What is the Difference?

In the dynamic world of packaging, one must constantly innovate to maintain a competitive edge. As we move through 2024, custom pouch packaging is standing

ISTA (International Safe Transit Association) certification is an essential component of the packaging industry. It involves testing and certifying packaging materials and products to ensure

In the realm of packaging, the size and weight of a package are more than just physical dimensions; they are critical factors that influence a