Home » Bubble Vs Foam Rolls: Which Should You Use For Shipping?

Bubble Vs Foam Rolls: Which Should You Use For Shipping?

We all want to protect our products during shipment, but are not quite sure on which product to use, often many of us find ourselves selecting either bubble or foam. Both are similar in purpose as they serve as a packaging protective solution, but they differ in application or in use. By understanding the difference between the two, you can better optimize your packaging efficiency and protection.

What Is a Bubble Roll?

Bubble Roll is a plastic sheet consisting of air bubbles that are designed to protect objects by restricting movement and absorbing damage. Bubble roll is available in a variety of sizes, thicknesses, applications, and additives. To apply a bubble roll, lay it out with the bubble side up and cover the product with wrap.

When To Use Bubble Roll

- Fragile items: glass, dishes, lights, mirrors, TVs, artwork, figurines, and other items susceptible to damage.

- Sensitive electronic products: bubble roll can be made with anti=static agents used to protect electronic devices from electrostatic discharge in addition to cosmetic damage.

- Furniture: bulking, odd shaped, or fragile furniture such as table tops, glass doors, coffee tables and other furniture often require plenty of protection against vibration and shocks.

- Sentimental Items: products that are of high value emotionally to consumers are often wrapped in bubble material to ensure the utmost care when shipping products or while placing them in storage. For example, jewelry made with your loved ones’ fingerprints engraved into it.

What You Should Know Before You Buy Bubble Roll

A Bubble roll is not the ideal solution for every packaging application. If you are not careful, then you can limit your packaging potential and accrue more overhead than you anticipated. You should be also mindful of the thickness of the bubble rolls as they can vary in size and strength.

Typically, when a product is wrapped in bubble material it becomes harder to stack that object. In addition, the air bubbles of the wrap take up a lot of free space that can be used to package more items. It can be quite costly to limit the amount of product you can send due to the drawbacks of bubble rolls.

However, there are many applications where bubble rolls are needed. It is very adaptable, versatile and can be used more than once. Its lightweight design makes it easy to handle for the manufacturer and end user.

If you are interested in bubble rolls, then contact Brown Packaging today to get supplied.

What Is a Foam Roll?

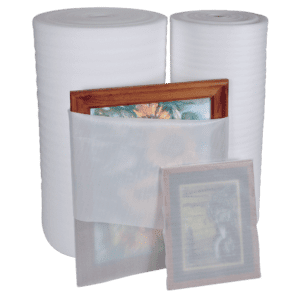

Foam rolls are made from expanded polyethylene with insulating and cushioning properties, which gives the wrap a dense, lightweight, thin and flexible design. It is manufactured into a roll that contains sheets of foam that can be cut into any size or shape. Like a bubble roll, foam can be designed with anti-static properties and other additives.

When To Use Foam Roll?

- Kitchenware: knives, forks, glass cups, dishes and small, sensitive and fragile kitchen appliances.

- Consumer goods: decorative items made with glass, small mirrors, picture frames, and other items.

- Cosmetics and personal care products: lotions, creams, oils, makeup, and other small and fragile items.

- Other fragile and sensitive items: medical devices, electronics, furniture legs, glass, ceramic, and other items.

What You Should Know Before You Buy Foam Roll

Before you buy foam rolls you should select the right thickness for your product. This may require you to ask the packaging provider what thickness is recommended for your size product, as thickness can vary from one supplier to another.

The benefit of foam rolls is that they are easier to stack and take up minimal space. However, it may be more expensive than using a bubble roll.

Summary: Bubble Vs Foam Rolls

Selecting between bubble and foam can be a difficult choice. They both have their uses and drawbacks. Ultimately, you want to package bulker, heavier, and extremely fragile products with bubble rolls. Foam can also be used for sensitive and fragile products, but can cost you more.

You can offset these costs and be more efficient if you plan on stacking items on top or fitting a larger quantity within a shipment. However, be mindful of how you package and ship your products as they may become damaged.

It may be best to seek the help of a packaging professional. If interested in bubble, foam, or cushioning packaging, then contact Brown Packaging today.

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

One of the biggest challenges in sustainable packaging is balancing environmental responsibility with product protection. Buyers often worry that switching to eco-friendly materials means sacrificing durability or driving up costs. In 2026, new material technologies allow brands to meet sustainability goals without compromising strength or supply chain performance. Why Protection Still Matters Damaged products create more waste than packaging ever could. Returns increase logistics costs and carbon emissions. Retailers and e-commerce platforms expect packaging to deliver both sustainability and reliability. Eco-Friendly Material Options Recycled corrugated: Maintains stacking strength while reducing virgin fiber use. Molded pulp inserts: Cushion fragile items while replacing plastic foam. Water-based barrier coatings: Add moisture resistance without plastic films. Compostable films: Ideal for short shelf-life or single-use applications. Paper-based mailers: Replace poly mailers for e-commerce shipments. How to Balance Eco Goals and Protection Use right-sizing to reduce material volume while improving fit. Apply hybrid solutions (corrugated + pulp) for high-value goods. Conduct ISTA testing to validate protective performance. Match material choice to product fragility and supply chain conditions. Examples in Action Electronics: Molded pulp trays replacing EPS foam. Food and beverage: FSC-certified corrugated with recyclable coatings. Retail e-commerce: Recycled paper mailers protecting apparel. Packaging Solutions with Brown Packaging Brown Packaging develops eco-friendly solutions that protect products while meeting sustainability requirements. From recycled corrugated to innovative coatings, our team ensures you never trade protection for environmental impact. Contact us to explore eco-material options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Eco-Friendly Packaging Materials and Case Studies. Retrieved from https://sustainablepackaging.orgASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Bubble Vs Foam Rolls: Which Should You Use For Shipping?

Polyethylene terephthalate, commonly abbreviated, stands out in the packaging industry for its versatility and environmental friendliness. Recognized as the most widely recycled plastic worldwide, this polymer combines clarity, durability, and lightweight properties, making it ideal for a diverse range of packaging applications. Understanding Polymer Packaging What Is This Material? This polymer is known for its robustness and chemical inertness. It is inherently clear, allowing for excellent visibility of the product inside, which is crucial for consumer goods. Its strength ensures it can handle the rigors of transport and retail environments without compromising the product’s integrity. Additionally, it is lightweight, reducing transportation costs and lessening the environmental impact. Eco-Friendly Aspects A significant advantage of this material is its sustainability. It can be recycled repeatedly without degradation in quality, contributing to a circular economy. Innovations in recycled content underscore the material’s role in promoting environmental sustainability. Benefits of Using This Polymer for Packaging Design Flexibility: The versatility allows it to be molded into various shapes and sizes—from standard rectangles to intricate designs. This flexibility enables brands to create unique packaging that stands out on the shelves and communicates the product’s message effectively. Moisture Resistance: Unlike materials such as cardboard, it retains its shape and integrity even in moist environments, protecting the product and maintaining the packaging’s aesthetic appeal. Lightweight and Durable: Despite its light weight, it is remarkably strong, providing excellent protection for the contents while reducing the overall weight of the package. This strength-to-weight ratio makes it an economical choice for manufacturers and distributors. Food Safety: The food-safe properties make it an ideal choice for food and beverage packaging, ensuring that products remain safe and uncontaminated from production to consumption. Applications of Polymer Packaging Its attributes make it suitable for a wide array of products: Food and Beverage: From bottled beverages to blister packaging for perishables, its clarity and safety are highly valued. Pharmaceuticals: It provides secure, tamper-evident packaging for medicines, ensuring product integrity and patient safety. Cosmetics and Personal Care: The aesthetic appeal and durability make it suitable for high-end cosmetics and everyday personal care products. Electronics and Gift Packs: The strong yet lightweight nature protects electronics and gifts while allowing for attractive, custom designs. Household Items and Toys: Its robustness makes it suitable for packaging various household goods and children’s toys, ensuring safety and durability. Why Choose Polymer Packaging? Choosing this material for your packaging needs means investing in a material that offers superior performance in both protection and presentation. It supports innovative design possibilities that can enhance brand perception and consumer attraction. Additionally, its environmental credentials help companies meet sustainability goals, an increasingly important factor in consumer decisions. For businesses looking to leverage these benefits, partnering with a provider like Brown Packaging, skilled in designing and producing high-quality solutions, is crucial. Such partnerships enable businesses to fully utilize the advantages of this material, from conceptual design to the final product. Whether for simple storage solutions or complex marketing displays, Brown Packaging offers a clear, sustainable choice that meets both practical and aesthetic needs effectively. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

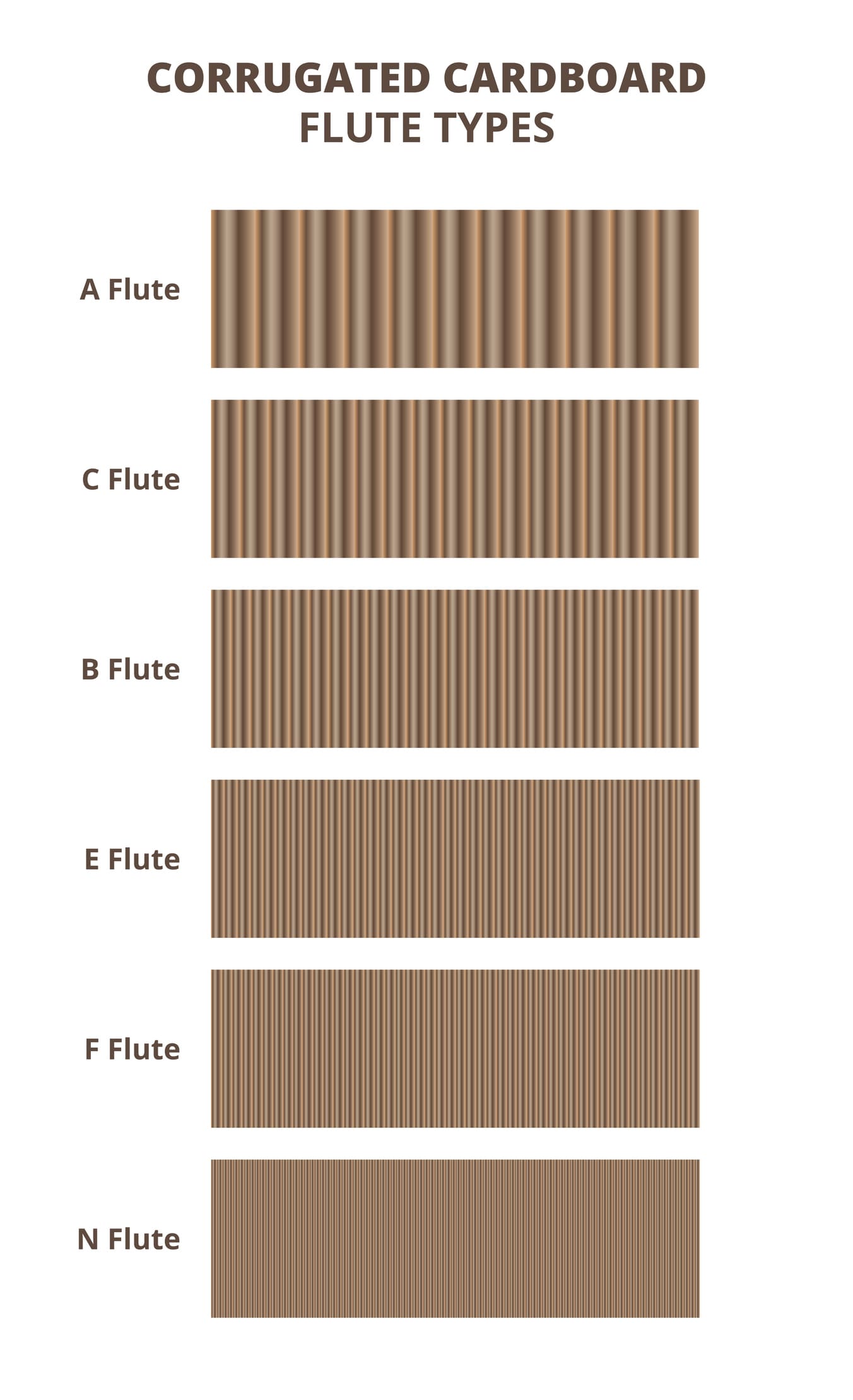

At a cursory glance, the humble cardboard box might seem like a straightforward item, yet it’s far more intricate and sophisticated than it initially appears. Deceptively simple, the construction of these boxes features numerous structural components that provide robustness, protection, and insulation, while offering an invaluable canvas for brand promotion. One of these often-overlooked components is the corrugated flute, a critical aspect of cardboard packaging that plays a vital role in the design and functionality of the box. This comprehensive guide will take a deep dive into corrugated flutes and their role in the packaging industry. Decoding Corrugated Flutes Corrugated flutes might escape the naked eye at first, but these wave-like patterns, nestled between the liner layers, form the very backbone of corrugated packaging. Integral to the composition of cardboard boxes, they turn these packages into sturdy containers, making them some of the most reliable methods for shipping and storage. Key Roles of Corrugated Flutes Corrugated flutes are much more than just layers of corrugated material. They play a central role in providing corrugated packaging with additional insulation and protection layers. Acting as the structural skeleton of the packaging, these flutes make the package crush-proof and puncture-proof, making it possible for boxes to bear the weight of heavy items without giving way or collapsing. To further understand the role of these flutes, let’s examine them in a typical shipping scenario. Packages often undergo considerable stress during transit, such as pressure from other boxes, jostling, or even puncture risks. The flutes within the corrugated box provide a cushioning effect that absorbs these shocks and helps protect the contents of the box. As a result, whether you’re shipping delicate glassware or weighty books, you can be confident that your items are secure within their corrugated packaging. A Detailed Look at the Five Types of Corrugated Flutes Not all corrugated flutes are created equal. The packaging industry employs five primary types of flutes, each serving specific needs and offering different benefits. Let’s explore these types in more detail: A Flutes With a thickness of approximately 5 millimeters or ¼ inch, the A flute is the thickest type available. Around 36 of these flutes can be found within a single linear foot of packaging, resulting in a highly robust structure for heavier items and excellent cushioning for delicate contents. A flute’s larger size provides optimal strength and compression properties, making it an excellent choice for products that require more support or have a higher risk of breakage. It’s no surprise then that A flutes are often used in packaging electronics, appliances, glass items, and other similar products. B Flutes The B flute, about 3.2 millimeters or ⅛ inch thick, falls into the mid-range category. With about 49 flutes per linear foot, it offers considerable crush and puncture resistance. B flutes provide an excellent surface for printing words, graphics, and logos directly onto the corrugated cardboard. Thanks to its combination of stiffness and compactness, the B flute is commonly used in retail packaging for items like canned goods. It is also commonly used in stand-up displays and for smaller boxes requiring a more refined print. Die cut boxes, generally use B – flute, as relatively small flute thickness helps when there a several scores and folds. C Flutes Being the second-thickest, C flutes measure around 3.2 millimeters or 11/64 inches in thickness, and about 41 flutes fit within a single linear foot. These flutes are ideal for shipping boxes due to their excellent resistance to crushing and compression. A C flute’s excellent stacking strength and printing capabilities make it a popular choice for transporting heavier products. Whether you’re moving a kitchen appliance or a batch of fresh produce, C flutes offer the durability and support needed. C- flute is the most popular thickness for general shipping boxes. E Flutes Second in thinness, E flutes are approximately 1.6 millimeters or 1/16 inch thick. As many as 90 flutes fit within a single linear foot, resulting in a lightweight but strong structure. The thinness of E flutes makes them an excellent choice for reducing storage space and costs. Because of its thinness and excellent printing surface, E flutes are commonly used in packaging consumer goods, particularly those requiring a more sophisticated presentation, such as cosmetics and high-end electronics. F Flutes The thinnest of all, F flutes measure around 0.8 millimeters or 1/32 inch in thickness. About 128 flutes can be found within a single linear foot, making them ideal for creating stiff packaging for specific consumer goods. Due to their thinness and smooth printing surface, F flutes are often used in retail packaging for luxury goods and other high-end items. Going Beyond Flutes: Board Types, Box Styles, and Printing Methods Understanding the world of corrugated packaging goes beyond flutes. There are several other critical considerations, such as board type, box style, and printing type. Each of these factors plays a vital role in determining the best packaging solution for specific products and brands. Board Type Corrugated packaging materials consist of a combination of flutes and liners, and this combination can vary depending on the packaging’s intended use. Let’s look at the four primary types of corrugated board: Single-face: As the name suggests, a single-face board consists of one layer of fluting and one liner layer. Although it’s not as durable as other types, its cushioning properties make it ideal for additional inner packaging components. Single-wall: This is the most commonly used board type, comprising one layer of fluting sandwiched between two liners. It offers sufficient insulation and protection, making it a popular choice for shipping cartons. Double-wall: Essentially two boxes in one, a double-wall board has three liner layers surrounding two layers of fluting. This super-durable board type is excellent for packaging heavy industrial items. Triple-wall: The most durable board type available, a triple-wall board has four liner layers and three fluting layers. It’s like having three boxes in one, which makes it ideal for robust applications such as extremely heavy metal pieces, equipment and chemical

Point of Purchase (POP) displays are an effective way to promote products and increase sales in retail environments. The trends for POP displays in 2023 are likely to focus on the following areas: Sustainability Technology Integration Personalization In-Store Experience Data-Driven Multi-Functionality Experimentation Sustainability As more consumers are becoming environmentally conscious, retailers are looking for ways to reduce the environmental impact of their POP displays. This includes using eco-friendly materials such as recycled corrugated or biodegradable plastics, bamboo, or other sustainable materials. For example, a retailer can use biodegradable or compostable materials in their POP displays to reduce plastic waste. Additionally, retailers are designing displays that can be easily recycled or repurposed at the end of their life, reducing the amount of waste generated by the retail industry. Technology Integration POP displays are increasingly incorporating technology such as digital screens, QR codes, and augmented reality to create interactive and engaging experiences for consumers. This allows retailers to provide customers with additional information and product demonstrations, while also collecting data on customer interactions. For example, retailers can use digital screens to display product videos, or allow customers to scan QR codes to receive discounts or additional information. Another example is retailers using virtual reality headsets to give customers a virtual product demonstration, or using RFID tags for interactive experiences. Personalization With the rise of digital marketing, retailers have access to more consumer data than ever before. This enables them to personalize their POP displays to target specific demographics and increase their effectiveness. For example, retailers can use data to create displays that are tailored to the specific interests and needs of different customer segments. This can include personalized offers, product recommendations, and other incentives. In-Store Experience As e-commerce continues to grow, retailers are looking for ways to create a unique and engaging in-store experience to lure customers away from online shopping. POP displays can be used to create immersive environments and encourage customers to stay in the store longer. This can include displays that use lighting, sound, and other sensory elements to create a more engaging experience. An example of this is creating a themed environment in the store, with POP displays that complement the theme. Data-Driven Retailers are using data to drive their POP display strategy. This includes using data to track consumer behavior, analyze sales data, and optimize their POP display strategy accordingly. For example, retailers can use data to determine which products are selling well and which displays are most effective, and then adjust their strategy accordingly. Another example is using data-driven insights to create a dynamic POP display that changes based on the time of day, weather or foot traffic. Multi-Functionality Retailers are looking for ways to maximize the use of their POP displays, so they are looking for multi-functional displays that can be used for multiple products and purposes. This can include displays that are modular and can be reconfigured to accommodate different products, or displays that can be easily repurposed for different promotions. An example of this is using a POP display that can be easily modified to display different products, like a modular shelving system. Experimentation With the rise of e-commerce, retailers are experimenting with new POP display styles and designs, such as holographic displays, to create a more memorable and unique in-store experience. This allows retailers to stand out from their competitors and create a more engaging and memorable customer experience. An example of this is using holographic displays to showcase products in a more interactive and engaging way. If you are interested in POP displays, then contact Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Displays Facebook Twitter LinkedIn Pinterest Relevant Posts