Home » What is Flexible Packaging?

What is Flexible Packaging?

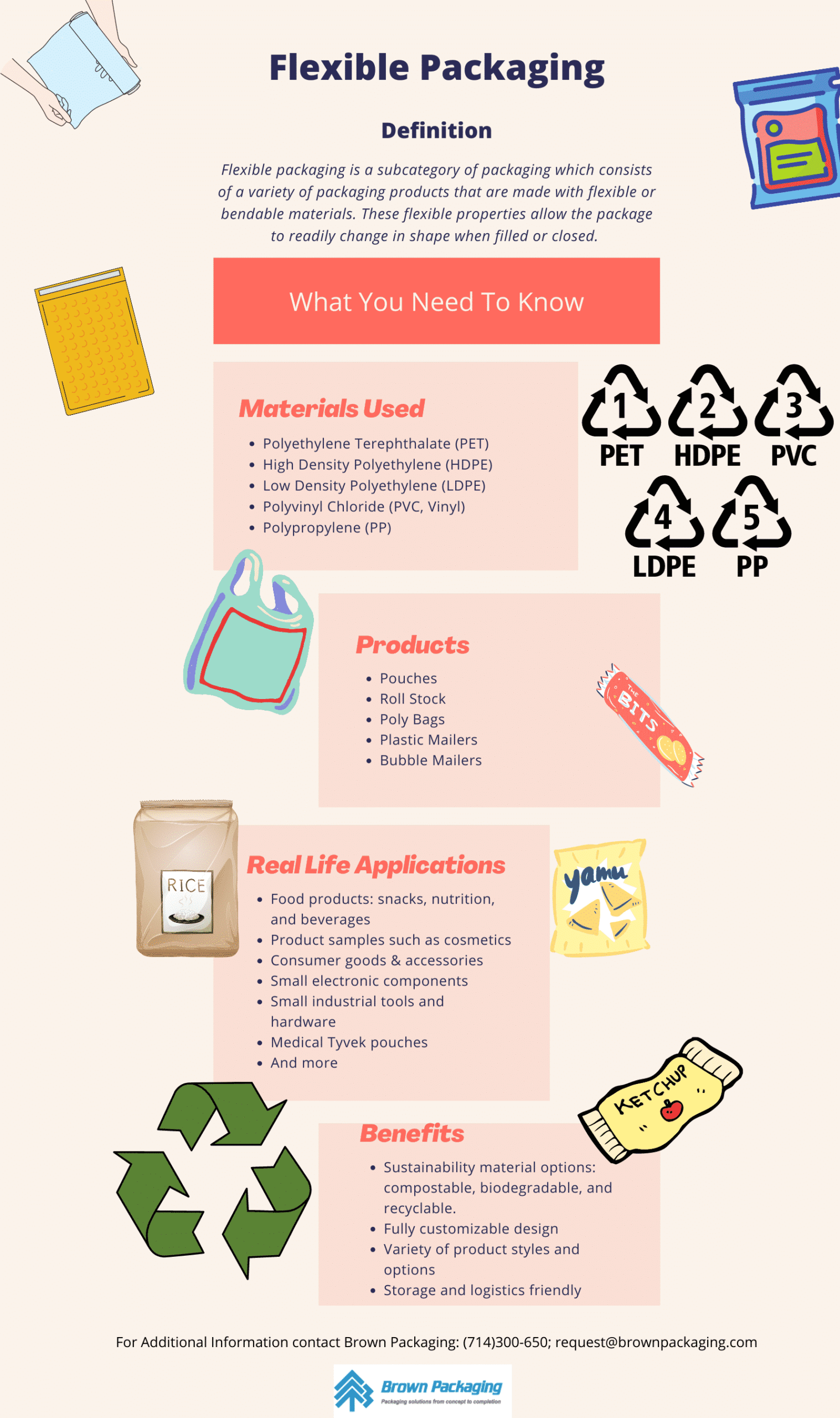

Flexible packaging stands out in the packaging industry for its adaptability and efficiency. Utilizing materials that can flex and mold, this type of packaging adjusts its shape when filled or sealed, catering to a diverse range of products. The evolution of material technologies has not only made flexible packaging more cost-effective but also reduced material consumption during manufacturing, positioning it as a preferable alternative to traditional rigid and corrugated packaging solutions.

Comprehensive Overview of Flexible Packaging

Materials Used in Flexible Packaging

The foundation of flexible packaging lies in its diverse material selection, each offering unique properties:

Low Density Polyethylene (LDPE): Commonly used for its softness and flexibility, ideal for products requiring heat sealing. It’s resistant to various chemicals and is predominantly used in food packaging and consumer goods.

High Density Polyethylene (HDPE): Known for its robustness and chemical resistance, making it suitable for household cleaning supplies, poly mailers, and items that encounter stress during shipping.

Polypropylene (PP): With its high heat resistance, PP is perfect for packaging products that may be exposed to heat, such as microwaveable foods and certain consumer electronics.

Polyethylene Terephthalate (PET): Offers excellent clarity and barrier properties against moisture and gases, widely used in the food and beverage industry.

Polyvinyl Chloride (PVC): Chosen for its durability and resistance to environmental factors, PVC is used in non-food packaging such as shrink films and sturdy containers.

Flexible Packaging Products and Their Applications

Flexible packaging can be customized to suit a broad range of applications, offering unique solutions that are both protective and promotional:

Pouches: Available in various styles such as stand-up, flat, and side gusset, pouches are popular for food products, cosmetics, and small consumer goods.

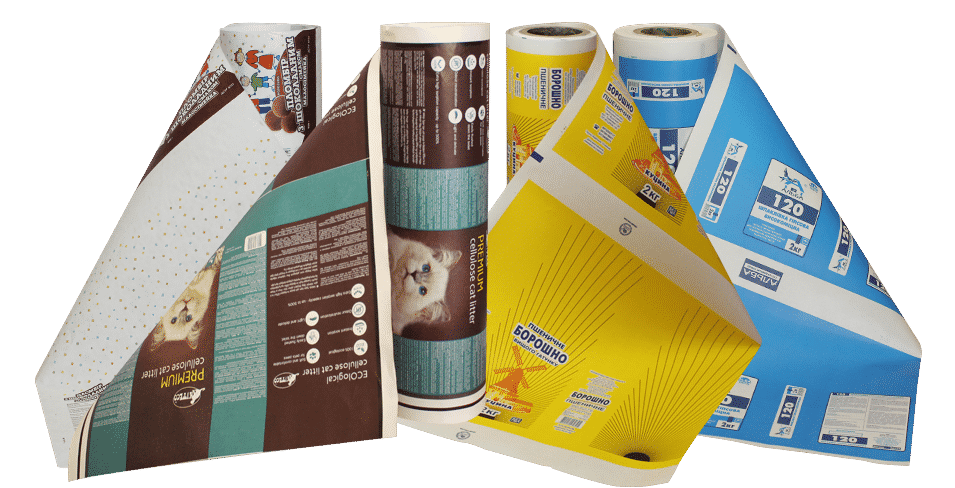

Roll Stock: This material is used to create custom bags or pouches, tailored to specific product dimensions, commonly used for snacks, candies, and nutritional bars.

Poly Bags: These versatile bags are suitable for a wide array of products, from apparel to food and electronics, featuring options like resealable closures and custom prints.

Plastic and Bubble Mailers: Designed for shipping, these mailers are lightweight, durable, and can include bubble cushioning for added protection.

Pouch

Roll Stock

Poly Mailer

Benefits of Flexible Packaging

The advantages of flexible packaging are numerous, making it a preferred choice for many businesses:

Environmental Impact: Many materials used in flexible packaging are recyclable, and ongoing advancements are enhancing biodegradable and compostable options.

Customization and Branding: Flexible packaging allows extensive customization in printing and design, enabling effective brand promotion and consumer engagement.

Cost Efficiency: The lightweight nature of these materials reduces shipping costs and decreases the overall environmental footprint.

Supply Chain Efficiency: Flexible packaging requires less storage space and can be transported more efficiently, allowing for more products per shipment compared to rigid packaging solutions.

Pouch

Roll Stock

Poly Bag

Conclusion: Flexible Packaging Explained:

Flexible packaging offers a dynamic approach to packaging, combining innovative material use with functional design to meet a variety of industry needs. Whether for food, pharmaceuticals, or consumer goods, flexible packaging provides tailored solutions that enhance product protection, display, and sustainability. For businesses considering this packaging option, understanding the specific material properties and potential applications is crucial for making an informed decision.

For further assistance and to explore flexible packaging solutions tailored to your needs, consider reaching out to packaging experts like Brown Packaging.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » What is Flexible Packaging?

When designing flexible packaging for perishables, customers often have initial ideas for graphics but lack clarity on functional aspects critical to product performance. Shelf life

When designing flexible packaging, one key consideration is how the product will be displayed: Will it be showcased individually on retail shelves or packed in

Roll stock flow wrap packaging is a versatile and efficient method used in the food and packaging industry to package a wide variety of products.