Home » Holiday Co-Packaging: Boost Efficiency and Brand Impact

Holiday Co-Packaging: Boost Efficiency and Brand Impact

Why Co-Packaging Becomes Critical During the Holidays

As the holiday season approaches, packaging teams are under pressure to deliver high volumes of promotional sets, combo packs, seasonal SKUs, and display-ready units—all with strict deadlines and compliance requirements. Co-packaging is the behind-the-scenes process that brings these programs together. It involves the final assembly, labeling, and packing of finished products into retail or shipping units, often across multiple components or brands.

During Q4, co-packaging isn’t just a convenience—it’s a strategic necessity. With limited time, increased SKU complexity, and fluctuating demand, outsourcing to a co-packer helps brands stay agile, reduce bottlenecks, and scale without sacrificing quality. It’s especially useful for:

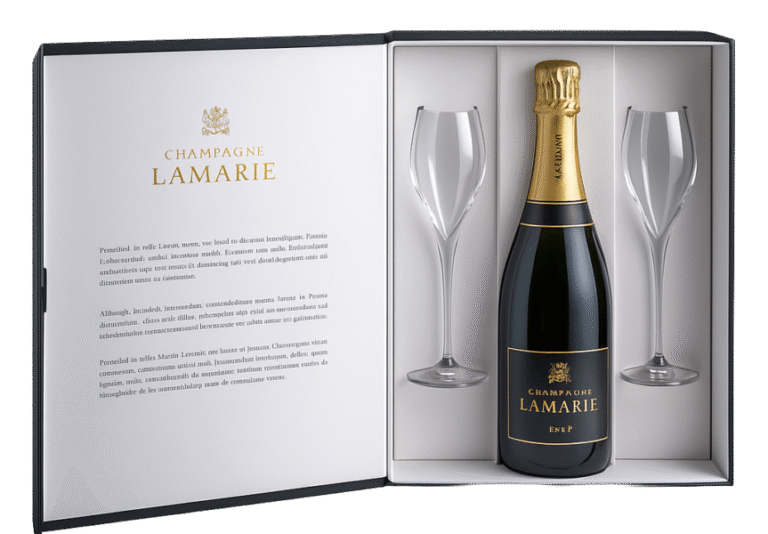

- Gift-ready promotional kits

- Seasonal value packs or multipacks

- Retail displays pre-packed by store or region

- Assortments containing items from different suppliers

Key Benefits of Holiday Co-Packaging

Speed and Flexibility

Co-packaging facilities are built for speed—capable of packing thousands of units per shift with rapid line changeovers. This allows you to adapt to late-breaking promos, changes in retailer demand, or packaging redesigns without derailing timelines.

Scalable Labor & Equipment

Rather than trying to stretch internal resources, you gain access to skilled labor, specialized automation (e.g., shrink tunnels, labeling machines), and the space to stage components and manage multi-SKU builds.

Custom Assembly with Quality Control

Whether assembling mixed bundles, adding branded sleeves, or applying tamper-evident features, trained teams ensure every unit meets specifications. This reduces repacks, chargebacks, and inconsistent customer experiences.

Retail & E-Commerce Compliance

From shelf-ready trays to e-commerce unboxing kits, co-packers handle labeling, bundling, and pallet configuration to meet strict retailer requirements—critical for holiday compliance.

What to Plan Ahead for Holiday Co-Packing

To avoid missed windows, brands should lock in co-packing programs by late summer. Lead times can shrink rapidly as more brands compete for space. When planning holiday co-packing:

- Forecast volumes and timelines clearly

Co-packers need visibility into SKU counts, component arrival dates, and packout quantities. - Define packaging specifications early

Finalize custom cartons, sleeves, and inserts with enough buffer to accommodate production and delivery. - Group projects by fulfillment destination

Packaging specs may vary depending on whether goods go to retailers, distributors, or DTC fulfillment centers. - Coordinate inbound shipments tightly

Co-pack success depends on having all components—packaging, product, inserts—arrive on time.

How Brown Packaging Helps Brands Execute Holiday Co-Packing

Brown Packaging offers end-to-end co-packaging support, including:

- Sourcing and supplying structural packaging components (RSC boxes, cartons, inserts, trays)

- Custom kitting, labeling, and multi-SKU packout

- Display assembly and palletization for retail-ready programs

- Compliance checks for shipping, handling, and storage

- Integrated supply chain coordination with your vendors and 3PLs

Whether you’re packaging 10,000 units for a national retail promotion or 2,500 custom e-commerce bundles, we help streamline every touchpoint from box design to packed pallet.

Final Takeaway

The holiday season is no time to gamble with last-minute fulfillment or overloaded internal teams. Co-packaging enables scale, speed, and brand consistency—all while letting your core team stay focused on strategy and growth. But capacity fills fast—start now to ensure your holiday campaigns stay on track.

Need co-packing support for the holidays? Let’s build your program together—contact Brown Packaging today.

In today’s competitive market, packaging affordability doesn’t start with cheaper materials — it starts with smarter design. Every score, fold, and insert decision affects not only how a box looks

Every brand is feeling the squeeze — higher raw material costs, volatile freight rates, and a consumer base more price-conscious than ever. But cutting packaging budgets blindly can lead to

Corrugated board comes in multiple flute sizes and wall grades, each designed to balance strength, weight, and cost. Selecting the wrong grade can lead to product damage, excessive freight costs,

As tariff changes reshape global trade, packaging buyers moving production from China to the U.S. or nearshore regions face a new challenge: supplier qualification. Transitioning supply doesn’t end once a

Home » Holiday Co-Packaging: Boost Efficiency and Brand Impact