Home » Why Corrugated Boxes are Strong?

Why Corrugated Boxes are Strong?

Corrugated boxes are strong because of their unique construction, which features a fluted corrugated sheet sandwiched between two flat linerboards. This design creates a robust structure that is both lightweight and capable of bearing significant weight and resisting impacts.

The Science Behind Corrugation

The strength of corrugated boxes comes from the principle of the arch, a design known for its ability to support weight and resist compression. The fluted sheet in corrugated boxes functions similarly, with each flute acting like a mini arch, providing resistance against crushing and impact from all directions. This corrugation not only adds rigidity and strength but also provides cushioning for the contents inside, absorbing shocks and vibrations during transport.

Multiple Layers for Enhanced Durability

Corrugated boxes typically consist of three layers: an inner liner, a medium (the corrugated or fluted layer), and an outer liner. This triple-layer construction distributes weight evenly and prevents punctures, tears, and other forms of damage. For items requiring additional protection, double-wall or even triple-wall corrugated boxes are available, adding more layers of fluting and linerboard, which significantly increases their strength and durability.

Material Quality

The strength of a corrugated box also depends on the quality of the materials used. High-grade paper provides a stronger foundation for the box, enhancing its load-bearing capacity and resistance to tearing. The type of adhesive used to bond the layers together also plays a critical role in the overall strength of the box. High-quality adhesives ensure that the layers remain firmly attached, maintaining the box’s structural integrity under stress.

Customization for Specific Needs

Another factor contributing to the strength of corrugated boxes is the ability to customize the flute size, paper grade, and wall construction based on specific requirements. For instance, larger flutes create more cushioning and resistance to compression, ideal for fragile items, while smaller flutes offer a smoother surface for printing and are better suited for lightweight products. This customization allows for the creation of boxes tailored to the weight, size, and vulnerability of the contents, ensuring maximum protection.

Environmental Factors

Corrugated boxes are designed to withstand a variety of environmental factors that can affect their strength. Many are treated with coatings or laminates to resist moisture, humidity, and temperature changes, which can weaken the paper fibers. By protecting against these external conditions, corrugated boxes maintain their structural integrity for longer periods, even in challenging shipping and storage environments.

The Role of Recycled Content

The incorporation of recycled materials in corrugated boxes has improved over the years, with advances in recycling technology ensuring that the strength of the boxes is not compromised. The use of recycled fibers, combined with virgin fibers, balances environmental sustainability with the need for durable packaging solutions. This blend ensures that corrugated boxes remain strong and reliable, even as they support recycling efforts and reduce the industry’s environmental impact.

Conclusion

The strength of corrugated boxes is the result of their unique construction, quality materials, and the science of corrugation. Their design maximizes strength while minimizing weight, making them an ideal choice for a wide range of packaging needs. From protecting fragile items during shipment to supporting heavy loads in storage, corrugated boxes offer a versatile, strong, and sustainable packaging solution. Whether for personal use or business logistics, the reliability of corrugated boxes stands unmatched in the packaging industry.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the

Home » Why Corrugated Boxes are Strong?

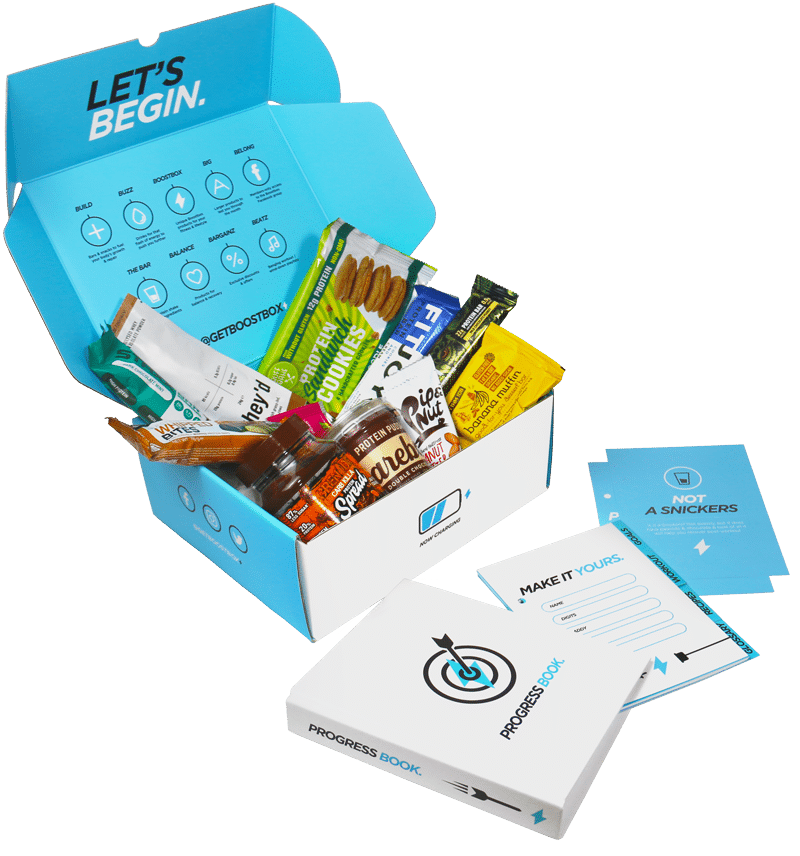

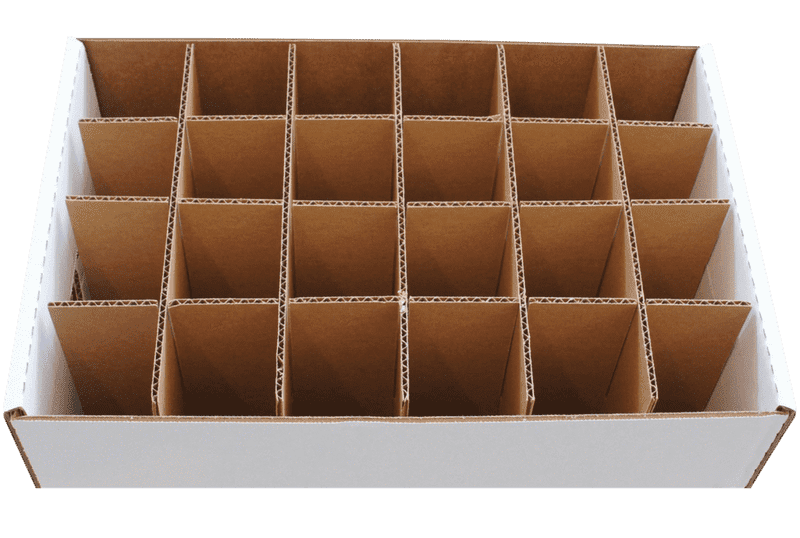

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard, a versatile and durable material widely used in the packaging industry. By incorporating partition inserts, boxes can be transformed into organized compartments, providing protection, support, and separation for the packaged items. In this blog, we will explore the various benefits and applications of corrugated partition inserts, as well as their contribution to sustainable packaging solutions. Benefits of Corrugated Partition Inserts Protection and Stability Corrugated partition inserts offer excellent protection for delicate or fragile items during transit. The inserts can be designed to fit snugly inside the box, creating individual compartments that prevent the packaged items from shifting or colliding with each other. This added stability minimizes the risk of damage and ensures that products arrive at their destination in optimal condition. Improved Organization and Presentation With corrugated partition inserts, boxes can be organized and segmented into multiple compartments, allowing for better item separation and organization. This is particularly beneficial for industries such as cosmetics, electronics, and food, where products need to be individually stored or displayed. The inserts also contribute to a visually appealing presentation, creating an attractive and professional appearance for the packaged items. Enhanced Efficiency in Handling and Storage Partition inserts streamline the handling and storage process by simplifying the identification and retrieval of specific items. By providing separate compartments for each product, inserts eliminate the need for time-consuming searching or sorting through a box full of items. This increased efficiency can greatly benefit distribution centers, warehouses, and retail operations. Customizability and Versatility Corrugated partition inserts can be customized to fit the specific dimensions and requirements of various products. Manufacturers can design inserts with different cell sizes and configurations, allowing for optimal placement and protection of items with different shapes, sizes, and fragility levels. This versatility makes partition inserts suitable for a wide range of industries and product types. Applications of Corrugated Partition Inserts Electronics and Technology: The electronics industry often deals with delicate components that require individual protection. Corrugated partition inserts can safeguard circuit boards, computer chips, and other electronic parts from damage during shipping. The inserts ensure that each component remains secure and isolated, reducing the risk of static discharge and other potential hazards. Pharmaceutical and Healthcare: In the pharmaceutical and healthcare sectors, the integrity and safety of products are paramount. Partition inserts can be utilized to separate and protect vials, syringes, medicine bottles, and other medical supplies. These inserts help prevent contamination, breakage, and the mixing of different substances, ensuring the quality and efficacy of pharmaceutical products. Food and Beverage: Corrugated partition inserts find applications in the food and beverage industry, particularly for the packaging of fragile or delicate food items. Inserts can keep items like glass bottles, jars, or delicate products secure and separate from one another, minimizing the chance of breakage or spoilage. Additionally, partitioned compartments can be used to package multiple items together, allowing for easy assembly of gift sets or sampler packs. Sustainability and Corrugated Partition Inserts Corrugated partition inserts contribute to sustainable packaging solutions in several ways: Recyclability Like corrugated cardboard boxes, partition inserts are recyclable and can be transformed into new paper products. By using recyclable materials, companies can reduce their environmental impact and support a circular economy. Reduced Material Consumption Partition inserts optimize the use of materials by providing individual compartments, eliminating the need for excessive cushioning or additional packaging. This reduces the overall material consumption and waste generation. Lightweight and Space-Efficient Corrugated cardboard partition inserts are lightweight, which helps reduce transportation costs and carbon emissions. Their space-efficient design allows for more products to be packed in a single shipment, maximizing the use of cargo space and minimizing the need for additional vehicles. Biodegradability Corrugated partition inserts are made from natural fibers, which means they are biodegradable. When disposed of properly, they break down naturally over time without releasing harmful pollutants into the environment. Renewable Material Source Corrugated cardboard is made from a renewable resource—trees. Responsible forestry practices ensure the sustainability of the raw materials used in the production of corrugated partition inserts, minimizing the impact on forests and promoting environmental stewardship. Summary: Corrugated Partition Inserts Corrugated partition inserts offer numerous benefits for packaging applications, ranging from enhanced protection and organization to improved efficiency and presentation. Their customizability and versatility make them suitable for a wide range of industries, including electronics, pharmaceuticals, and food and beverage. Moreover, these inserts contribute to sustainable packaging solutions by being recyclable, lightweight, space-efficient, biodegradable, and sourced from renewable materials. By incorporating corrugated partition inserts into their packaging designs, companies can enhance the functionality of their boxes while minimizing their environmental footprint. If you are interested in corrugated partitions or other types of inserts, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

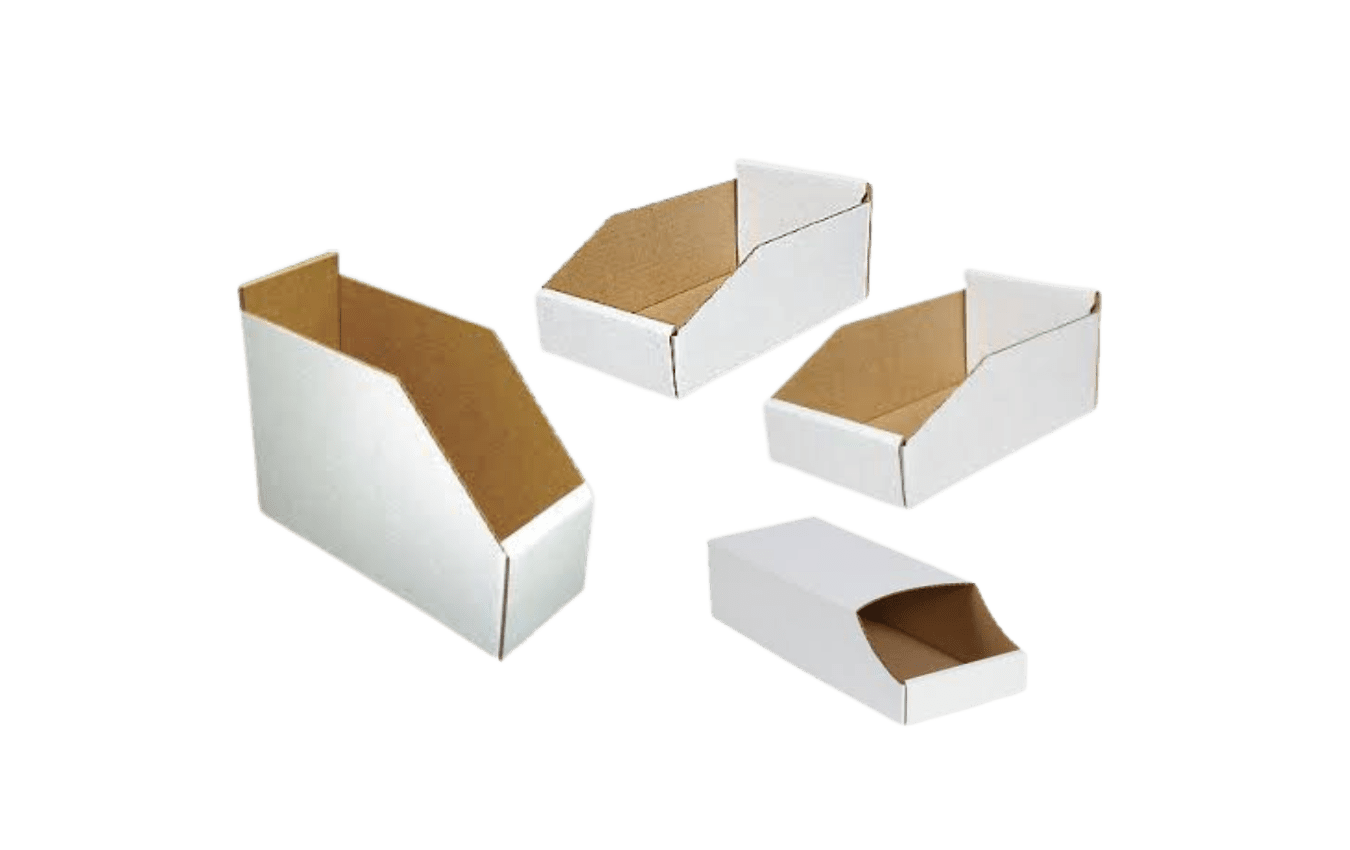

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it comes to keeping products organized, safe, and easily accessible. Whether you’re running a business or just looking for ways to declutter your space, corrugated bin boxes might just be the answer to your organizational needs. What are Corrugated Bin Boxes? Before diving into their benefits, let’s understand what they are. Corrugated bin boxes, often made from corrugated fiberboard, are storage containers designed for storing, organizing, and categorizing small to medium-sized items. You might have seen them in workshops, warehouses, or even craft rooms. Benefits of Using Corrugated Bin Boxes Durability and Strength: Made from corrugated fiberboard, these boxes have a unique fluted structure that offers strength and resilience. They can hold heavy items without collapsing, and their durability ensures they last a long time. Customizable: These boxes come in various sizes and can be tailored to fit specific spaces or needs. Some suppliers even offer custom printing, so businesses can brand their storage solutions or add labels for better organization. Eco-friendly: Since they are primarily made from recycled materials, corrugated bin boxes are a green choice. And when they’ve reached the end of their lifespan, they’re 100% recyclable! Cost-effective: In comparison to plastic bins or metal storage systems, corrugated bin boxes tend to be more affordable. This makes them an ideal choice for businesses that need bulk storage solutions. Space-efficient: Their design allows for easy stacking, saving floor space. When labeled properly, products can be found and accessed quickly, increasing efficiency and productivity. Protection: Corrugated boxes provide a buffer against external forces. Their structure allows for some cushioning which can protect the contents from minor impacts. Applications and Uses Retailers: Corrugated bin boxes can keep backstock organized, making inventory management a breeze. Warehouses: These boxes are perfect for categorizing parts or products, making it easy for workers to locate and pick items. Craft rooms: Artists and crafters can store beads, buttons, threads, and other small items, keeping their workspace tidy and their materials easily accessible. Garages: These boxes can be used to organize tools, nuts, bolts, and other small parts, ensuring that everything has its place. Tips for Effective Use Labeling is Key: Always label your boxes. It helps in quick identification and retrieval of items. Consider using large, clear labels and possibly color-coding for different categories. Regularly Review Contents: Periodically check the contents of your boxes. Remove any items that are no longer needed, and make sure everything in the box belongs there. Keep Like Items Together: Group similar items or those that are used together. For instance, if you’re using boxes in a workshop, keep all screws in one box and nails in another. Consider Shelving: To maximize the benefits of these boxes, consider using shelving units. This elevates the boxes, making them easier to access and saving floor space. In conclusion, corrugated bin boxes are an exceptional organizational tool. Their versatility, durability, and cost-effectiveness make them a top choice for both businesses and individuals. The next time you find yourself drowning in clutter or struggling to streamline your inventory, consider the humble corrugated bin box. It might just be the organizational magic you’ve been searching for. If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Design Foam Folding Carton Packaging Plastic Packaging Pouch Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Corrugated Bin Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

The Edge Crush Test (ECT) is a critical performance metric for corrugated boxes, directly correlating to stacking strength and load-bearing capacity. In the high-stress world of e-commerce shipping, where packages face frequent handling, multi-stop routes, and varying climates, optimizing ECT values without over-engineering is essential for cost efficiency and product protection. Why ECT Matters in E-Commerce Stacking Strength: Determines how well boxes can withstand vertical loads in warehouse racking or trailer stacking. Material Efficiency: Allows engineers to achieve performance targets with lighter weight liners or mediums, reducing costs. Regulatory Alignment: Certain carriers and industry sectors specify minimum ECT ratings for compliance. Balancing ECT and Basis Weight ECT vs. Mullen Burst: ECT measures column strength; Mullen measures resistance to puncture/tearing. E-commerce often favors ECT for stacked pallet loads. Lightweighting Strategies: Use high-performance recycled fiber blends to maintain stiffness. Incorporate higher-grade outer liners for localized reinforcement. Design Variables That Influence ECT Flute Profile: B- and C-flutes offer different stiffness profiles. B-flute generally yields higher ECT for the same board weight. Adhesive Quality: Uniform glue lines prevent micro-buckling under compression. Moisture Resistance: High humidity can reduce ECT by up to 50%; moisture-resistant coatings help maintain performance. Testing and Standards ASTM D642: Measures box compression strength. TAPPI T839: Determines edgewise compressive strength of corrugated fiberboard using the clamp method. ISTA Series: Full-scale distribution simulation, including drop, vibration, and compression under varying conditions. Optimization in Practice Case Example: Switching from 44 ECT double-wall to 32 ECT single-wall with enhanced flute medium reduced material cost by 14% without increasing damage claims in a 90-day trial. Prototyping: Lab ECT data should be validated through route-specific field testing before large-scale rollout. ReferencesASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.htmlTechnical Association of the Pulp and Paper Industry. (2018). TAPPI T839 om-18: Edgewise compressive strength of corrugated fiberboard using the clamp method. TAPPI. https://www.tappi.org/content/store/shared/T839.htmlInternational Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/ (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts