Home » The Ultimate Guide to Print Options for Custom Corrugated Boxes

The Ultimate Guide to Print Options for Custom Corrugated Boxes

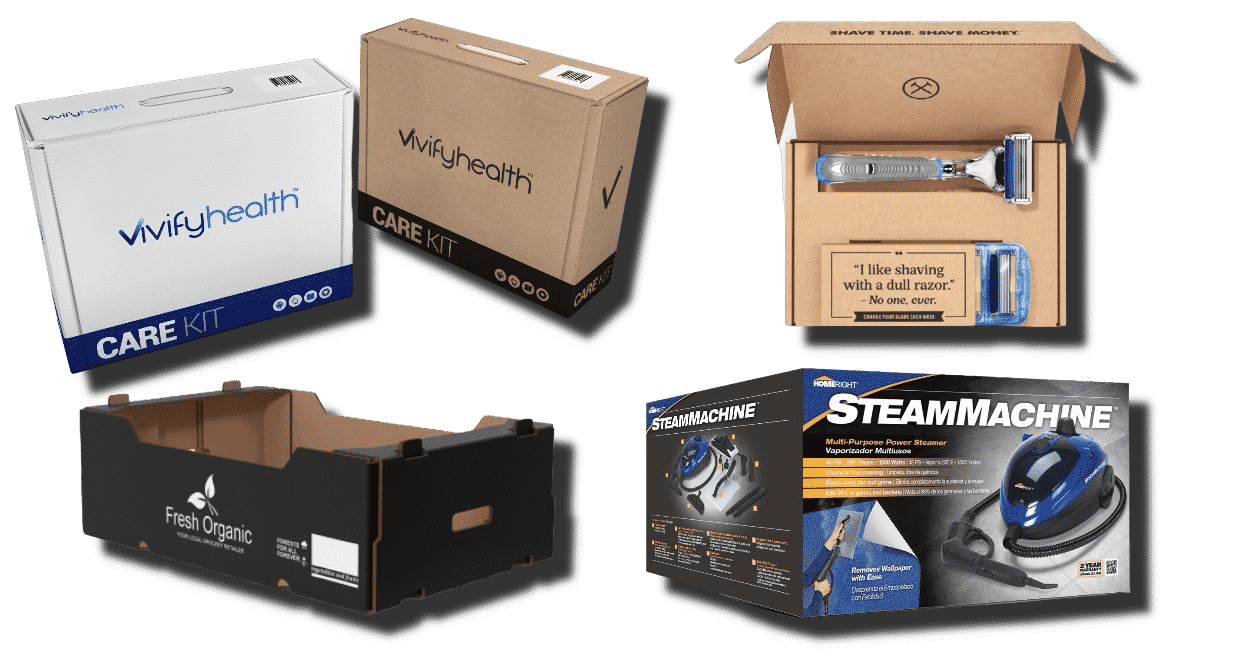

Custom corrugated boxes, owing to their versatility, durability, and eco-friendliness, have become a crucial tool for businesses seeking to maximize their packaging appeal. In today’s competitive market, where every detail counts, a bespoke print on your corrugated box can be the differentiating factor that elevates your brand above the rest.

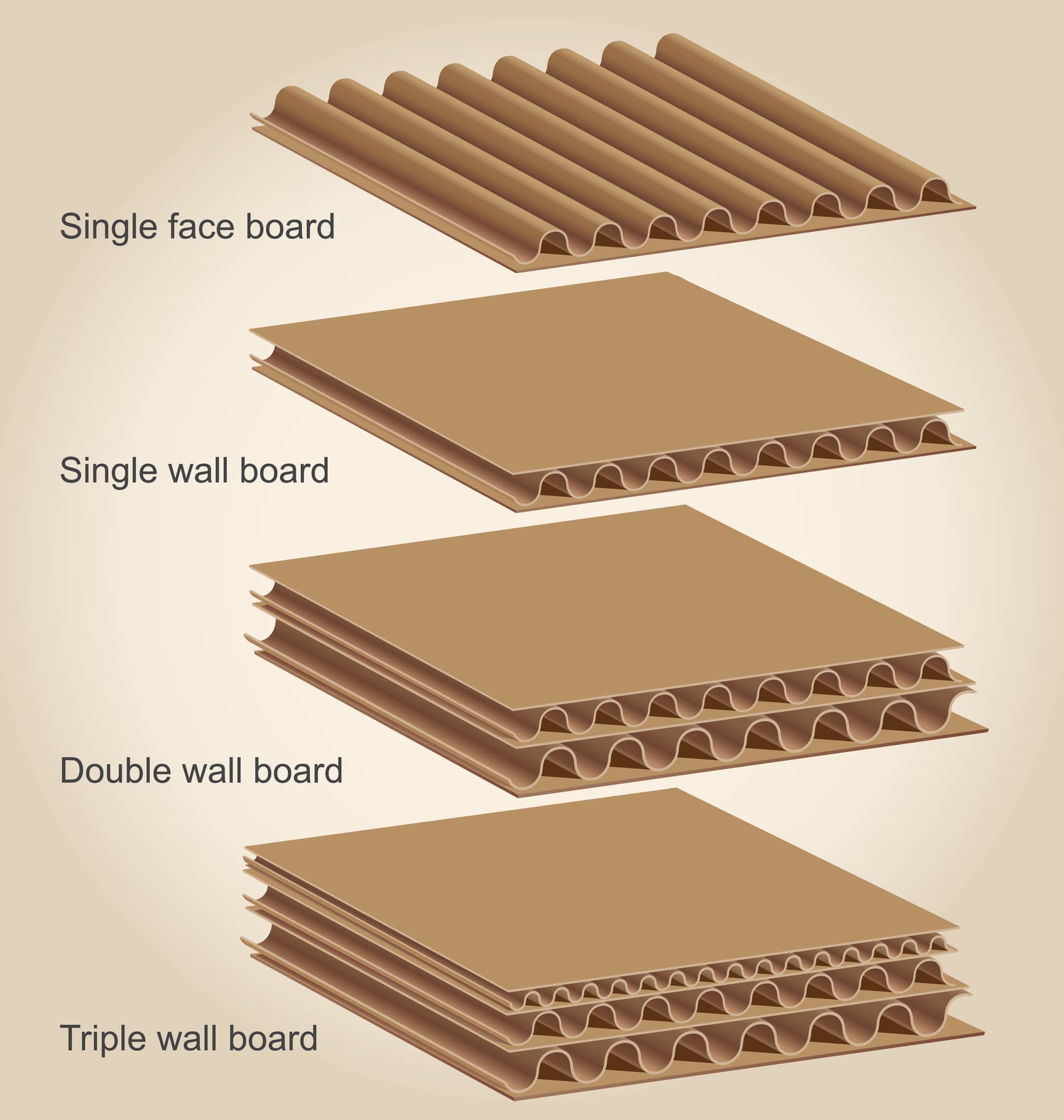

Understanding Corrugated Boxes

Before diving into the printing methods, let’s understand the foundation – the corrugated box itself. Crafted from corrugated cardboard which consists of a fluted layer nestled between two flat liners, these boxes are renowned for their strength. This unique structure not only ensures product safety but also provides an optimal surface for various print methods.

The Case for Custom Printing

So, why should one invest in custom printing? Beyond the obvious aesthetic appeal, custom printed boxes offer functional advantages. They facilitate smoother inventory management, as labels and prints assist in quick content identification. Additionally, a custom design brings a touch of professionalism, subtly signaling to clients and partners that you care about every aspect of your business, down to the boxes you use. And let’s not forget promotion; the surface of your box can be a canvas for marketing messages or spotlight promotions.

Flexographic Printing

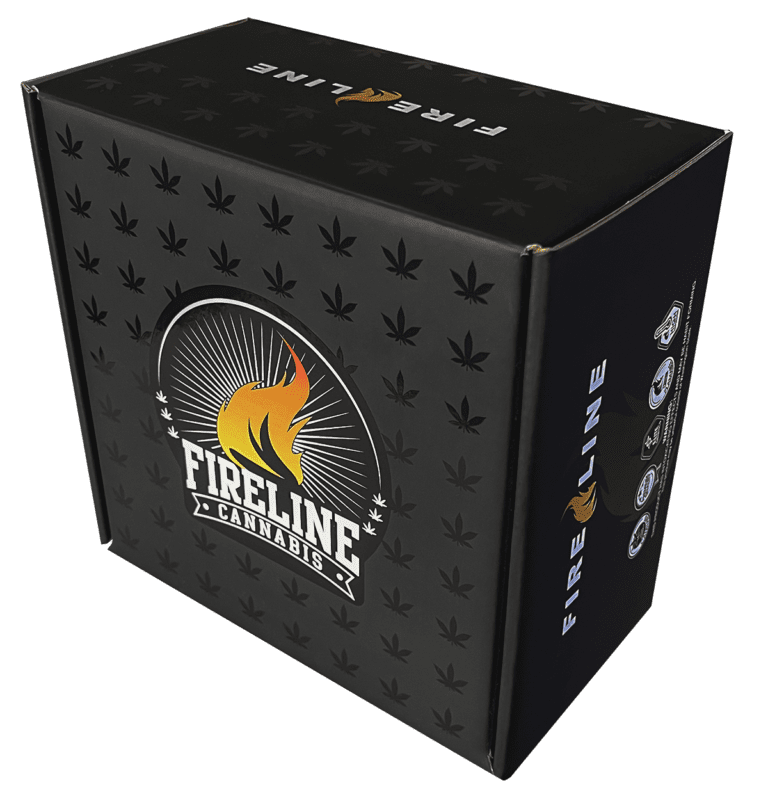

Flexographic printing, often compared to traditional letterpress printing, stands out for its adaptability to print on a wide range of substrates. This method uses flexible relief plates that transfer ink onto the box’s surface. When you have large-volume orders but wish to keep costs in check, flexographic printing offers a reliable solution. Its strength lies in producing large batches efficiently, and the prints dry relatively quickly.

Digital Printing

Evocative of the common home inkjet printers but on a much grander scale, digital printing promises precision. Perfect for businesses looking to place smaller orders or those desiring intricately detailed graphics, this method doesn’t necessitate printing plates, enabling quicker turnaround times. The real allure of digital printing, however, is its impeccable accuracy, ensuring each design is replicated to perfection.

Litho Laminating and Single Face Printing

Litho laminating is akin to artistry in the world of box printing. Here, a high-resolution printed paper sheet (the litho label) gets glued meticulously onto the corrugated material. It’s the go-to for businesses keen on delivering a retail experience that speaks of luxury and attention to detail. The resultant boxes often have a glossy, upscale appearance.

Spot UV Printing

A technique that’s both subtle and impactful, Spot UV printing introduces a tactile dimension to box printing. Specific areas are cured using UV light, giving them a glossy, raised appearance. This is not just about aesthetics; it’s a sensory experience, making logos or particular design features truly pop.

Green Printing

The print industry has been conscious of its environmental footprint, leading to the emergence of eco-friendly inks and coatings. Water-based inks, for instance, have become popular as they are significantly less harmful than their solvent-based counterparts. UV-curable inks are also gaining traction for being free from volatile organic compounds (VOCs). Biodegradable coatings, on the other hand, ensure that the environment doesn’t pay the price for our aesthetic pursuits.

Designing for Print

In the realm of print, understanding your audience remains paramount. Tailor your designs with your target demographic at the forefront of your mind. Consistency is key, so incorporate brand colors and motifs, ensuring that the box is an extension of your brand identity. Lastly, while it’s tempting to fill every inch with design elements, sometimes less truly is more. Effective use of white space can deliver a design that’s both impactful and elegant.

In Conclusion

Custom printing on corrugated boxes is that detail that can set you apart. Armed with knowledge about the diverse printing techniques available, you’re well-placed to make a decision that aligns with your brand’s ethos, aesthetic preferences, and budget.

If you are interested in printed corrugated boxes, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » The Ultimate Guide to Print Options for Custom Corrugated Boxes