Home » Auto Bottom vs. Tuck End Folding Cartons

Auto Bottom vs. Tuck End Folding Cartons

In the packaging industry, the design of a carton can significantly impact both the presentation and functionality of a product. Among the various styles available, auto bottom and tuck end folding cartons are popular choices, each with its distinct advantages. This blog post explores when to use an auto bottom carton versus a tuck end (straight or reverse) folding carton, helping you make an informed decision based on your product’s specific needs.

Understanding Auto Bottom Folding Cartons

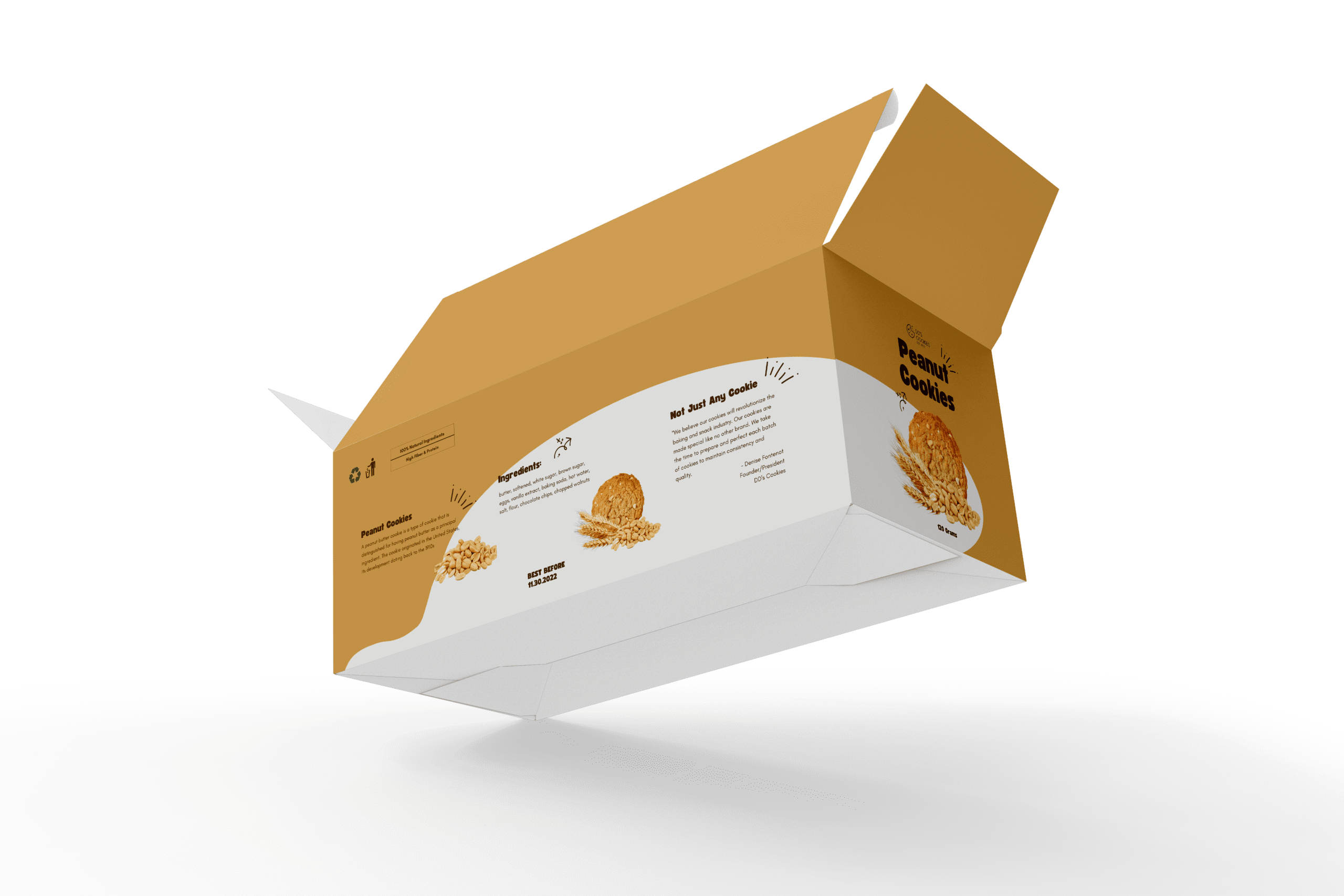

Auto bottom cartons are designed for ease of assembly and durability. They feature a pre-glued bottom that automatically snaps into place when the carton is opened.

- Ease of Assembly: Ideal for efficiency in packing processes, as they can be quickly and easily assembled.

- Durability and Strength: The auto bottom design provides a strong and stable base, making these cartons suitable for heavier items.

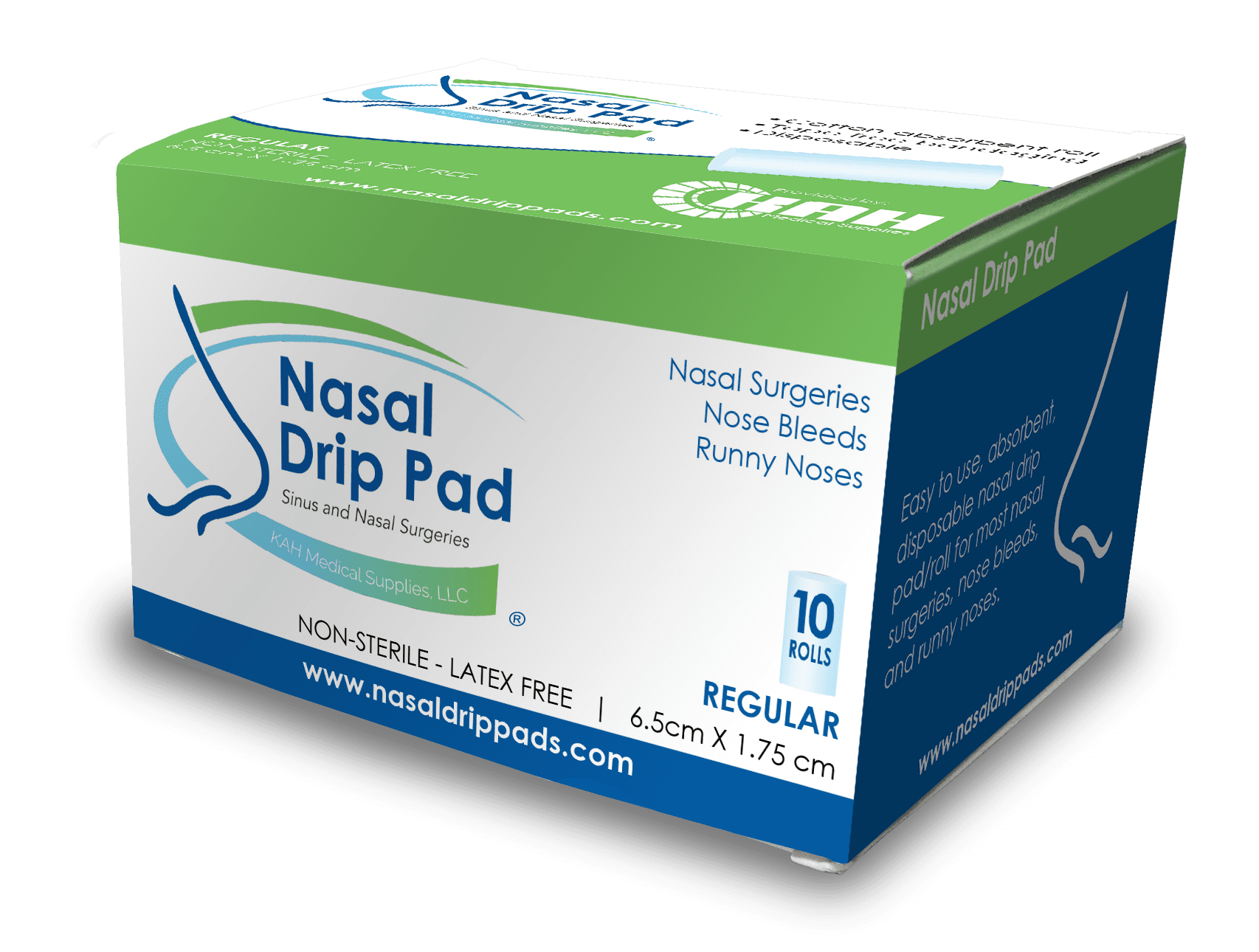

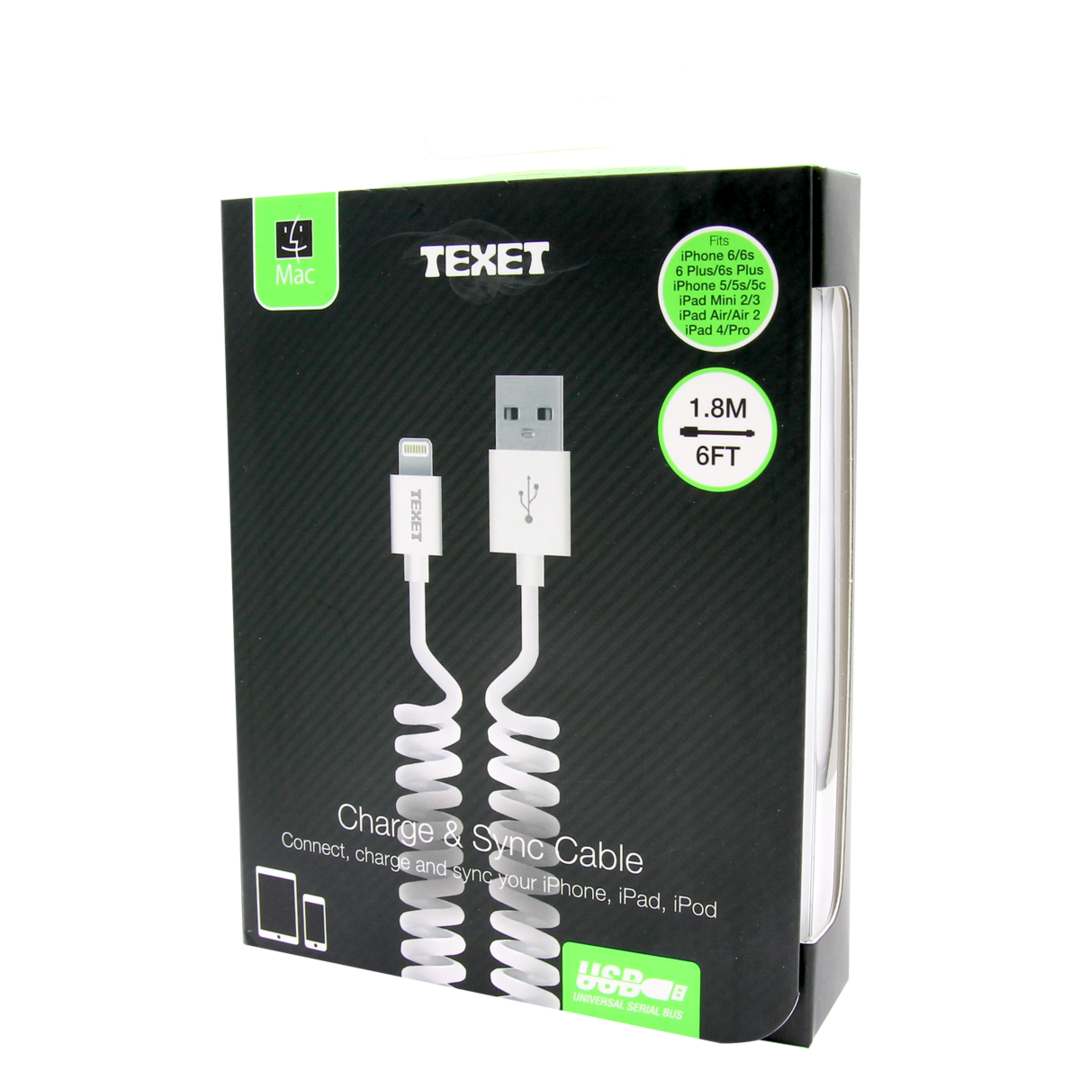

- Applications: Commonly used for products like cereals, frozen foods, and electronics that require sturdy packaging.

Exploring Tuck End Folding Cartons

Tuck end cartons come in two main types: straight tuck end and reverse tuck end. Both involve tucking flaps at one or both ends of the carton, but they differ in the direction in which the flaps close.

- Straight Tuck End:

- Flaps tuck in the same direction, providing a clean, uniform look.

- Ideal for products where presentation is key, such as cosmetics or pharmaceuticals.

- The continuous surface is excellent for showcasing branding and product information.

- Reverse Tuck End:

- Flaps tuck in opposite directions, offering a secure closure.

- More stable when standing up than straight tuck end.

- Commonly used for lighter items, including consumer goods and food products.

When to Use Auto Bottom Cartons

Auto bottom cartons are particularly useful in the following scenarios:

- For Heavier Products: Their structural integrity makes them ideal for heavier items that require additional support at the base.

- High-Speed Assembly Requirements: If your packing process demands speed and efficiency, auto bottom cartons are a time-saver.

- Automated Packing Lines: They are well-suited for automated packaging systems, reducing manual labor and increasing productivity.

When to Opt for Tuck End Cartons

Tuck end cartons are preferred in situations where:

- Aesthetics Matter: If your product requires a high level of shelf appeal, straight tuck end cartons offer a sleek and clean presentation.

- Versatility in Packaging: Both straight and reverse tuck end cartons can accommodate a variety of products and are easily customizable in terms of size and design.

- Cost-Effectiveness: Particularly with reverse tuck end cartons, they can be more economical, making them suitable for products with tight budget constraints.

Customization and Branding

Both auto bottom and tuck end cartons offer excellent opportunities for customization and branding.

- Printing and Finishing Options: You can enhance the cartons with various printing techniques, finishes, and textures to make your product stand out.

- Sustainability Options: Consider eco-friendly materials and inks to appeal to environmentally conscious consumers.

If you are interested in custom folding cartons such as auto bottom, straight tuck end, reverse tuck end, or any other style, then partner with Brown Packaging today to get started.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Auto Bottom vs. Tuck End Folding Cartons

In the packaging industry, the design of a carton can significantly impact both the presentation and functionality of a product. Among the various styles available, auto bottom and tuck end folding cartons are popular choices, each with its distinct advantages. This blog post explores when to use an auto bottom carton versus a tuck end (straight or reverse) folding carton, helping you make an informed decision based on your product’s specific needs. Understanding Auto Bottom Folding Cartons Auto bottom cartons are designed for ease of assembly and durability. They feature a pre-glued bottom that automatically snaps into place when the carton is opened. Ease of Assembly: Ideal for efficiency in packing processes, as they can be quickly and easily assembled. Durability and Strength: The auto bottom design provides a strong and stable base, making these cartons suitable for heavier items. Applications: Commonly used for products like cereals, frozen foods, and electronics that require sturdy packaging. Exploring Tuck End Folding Cartons Tuck end cartons come in two main types: straight tuck end and reverse tuck end. Both involve tucking flaps at one or both ends of the carton, but they differ in the direction in which the flaps close. Straight Tuck End: Flaps tuck in the same direction, providing a clean, uniform look. Ideal for products where presentation is key, such as cosmetics or pharmaceuticals. The continuous surface is excellent for showcasing branding and product information. Reverse Tuck End: Flaps tuck in opposite directions, offering a secure closure. More stable when standing up than straight tuck end. Commonly used for lighter items, including consumer goods and food products. When to Use Auto Bottom Cartons Auto bottom cartons are particularly useful in the following scenarios: For Heavier Products: Their structural integrity makes them ideal for heavier items that require additional support at the base. High-Speed Assembly Requirements: If your packing process demands speed and efficiency, auto bottom cartons are a time-saver. Automated Packing Lines: They are well-suited for automated packaging systems, reducing manual labor and increasing productivity. When to Opt for Tuck End Cartons Tuck end cartons are preferred in situations where: Aesthetics Matter: If your product requires a high level of shelf appeal, straight tuck end cartons offer a sleek and clean presentation. Versatility in Packaging: Both straight and reverse tuck end cartons can accommodate a variety of products and are easily customizable in terms of size and design. Cost-Effectiveness: Particularly with reverse tuck end cartons, they can be more economical, making them suitable for products with tight budget constraints. Customization and Branding Both auto bottom and tuck end cartons offer excellent opportunities for customization and branding. Printing and Finishing Options: You can enhance the cartons with various printing techniques, finishes, and textures to make your product stand out. Sustainability Options: Consider eco-friendly materials and inks to appeal to environmentally conscious consumers. If you are interested in custom folding cartons such as auto bottom, straight tuck end, reverse tuck end, or any other style, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

What is Chipboard? Chipboard is made from small wood particles mixed with resin, binders and other additives, which is then pressed together under high temperature with high amounts of pressure. It is thicker than normal paper, but doesn’t have flutes like corrugated boxes. Chipboard normally comes in a single layer material, but it can come in a variety of thicknesses dependent on your packaging needs. This type of packaging is not meant for shipping purposes, it is best used for small consumer goods. For the purposes of this blog SBS, CCNB, CNK, SUS, and other similar products are included in this chipboard category. Advantages: Cost Efficient: Lower production and shipping cost. Better for Storage: Takes up less space when being stored compared to other packaging products. Printing: Ideal for design and customization and can be directly printed on. Flexible: Easier to cut, fold and shape due to thinner material. Protection: The density of the material gives strength and protection against possible damage. Environmental Factors: It is made from recycled material. The energy used to create this product is far less than other packaging options. Disadvantage: Chipboard cannot hold heavy or fragile Items and does not offer as much protection compared to other materials like corrugated. What are Common Chipboard Applications? Chipboard is best suited for retail and lightweight displays because this material can be cut and folded into different sizes and thicknesses. Since it is easily customized and printed directly on, it allows for pictures and high-quality designs to be printed directly on the chipboard surface, as opposed to needing secondary labels. It is best used for lightweight and less valuable products due to it not being as strong as corrugated material. Most packaging seen in retail is chipboard material. Examples of this include packaging food, beauty products, pharmaceuticals and other retail items. What are the Chipboard Packaging Products? Folding cartons: Thin flexible paperboard or chipboard cartons used in packaging lightweight products. There are several different folding carton styles some being; Straight Tuck End, Reverse Tuck End, Auto Bottom, Full Seal, Shelf Displays and many other styles. Setup Boxes: Premium two-piece boxes used to protect luxury items. Inserts: Protect items and prevent them shifting from fulfillment to completion. Pads: Used to provide products with extra protection and separate layers. Straight Tuck End (STE) Folding Carton with hanging tab Setup Box (Rigid Box) Inserts Pads Is Chipboard Right for your Packaging needs? Deciding which packaging material will work best for your business needs is an important decision. You must take many factors into consideration when weighing your options. If you are looking for a light weight, cost efficient, highly customizable, and ecofriendly packaging option, then chipboard might be the best option for your packaging needs. If you are needing help deciding if chipboard is the right packaging material for you, contact Brown Packaging today and one of our packaging specialists will assist you. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Folding Cartons Facebook Twitter LinkedIn Pinterest Relevant Posts

Folding cartons are one of the most versatile forms of retail packaging—and how you print on them can make the difference between a product that blends in and one that commands attention. Strategic printing isn’t just about aesthetics; it’s about communicating value, increasing shelf appeal, and making your packaging work harder without adding cost. Here’s how to use print effectively to elevate your folding cartons—whether you’re working with skincare, supplements, food, electronics, or lifestyle products. Use Print to Create Visual Hierarchy Your folding carton only has a few seconds to make an impression on the shelf. Strategic printing helps guide the customer’s eye to what matters most. Tips: Use bold, contrasting colors or finishes (spot UV, foil) to highlight your brand name or logo Place key selling points (benefits, claims, features) front and center using larger font sizes Use typography and spacing to separate messaging and improve readability ✅ Helps the customer immediately understand what your product is and why it matters ✅ Improves visual impact without changing the structure ✅ Reduces reliance on costly redesigns by making the most of layout Match Print Quality to Product Value Your packaging should reflect the value of the product inside. Low-quality print on a premium item creates confusion—or worse, distrust. Use printing to reinforce brand perception. Recommendations: For high-end products, use offset or digital printing with high-resolution artwork Consider soft-touch coating, foil stamping, or embossed logos to enhance tactile appeal For entry-level products, clean flexo printing with sharp colors and simple messaging works well ✅ Aligns packaging with price point ✅ Builds customer trust and perceived quality ✅ Supports brand consistency across SKUs Make the Most of Every Panel Most folding cartons have six printable panels—front, back, two sides, top, and bottom. Don’t waste the real estate. Strategies: Use side panels for storytelling: sustainability efforts, brand values, QR codes Use bottom or inner flaps for certifications or required disclosures Add interactive elements (e.g., scan-to-learn codes) to drive post-purchase engagement ✅ Adds value without extra packaging ✅ Keeps primary panels clean and uncluttered ✅ Improves consumer education and brand connection Use Print to Simplify SKU Management For brands managing multiple SKUs or flavor/variant lines, digital printing or smart layout choices can reduce production complexity. Tactics: Create a shared dieline with only small design changes per SKU (e.g., color blocks, product names) Use black plate changes to keep core branding consistent while personalizing each version Leverage short-run digital printing for seasonal or promotional packaging ✅ Reduces setup and plate costs ✅ Increases flexibility for new launches ✅ Speeds up time to market for new variants Print for Retail Compliance Many retailers—especially in food, supplement, and cosmetic categories—have strict requirements around what’s displayed and where. Best practices: Print barcodes and expiration dates in scannable, clearly defined areas Use appropriate font sizes and spacing for ingredients, warnings, or supplement facts Leave space for lot coding or labeling if filled after printing ✅ Helps avoid costly chargebacks or relabeling ✅ Ensures legal compliance and customer clarity ✅ Streamlines vendor approvals Create a Memorable Unboxing Moment Folding cartons aren’t just for shelves—they also deliver an unboxing experience. The inside of the carton is an underutilized branding space. Ideas: Print a thank-you message or tagline inside the top flap Include hidden branding, illustrations, or QR codes inside the box Use the interior to reinforce key product benefits or cross-sell other products ✅ Turns packaging into a brand moment ✅ Encourages sharing and customer loyalty ✅ Adds value without structural changes Keep Production Methods in Mind Not every finish or design choice works with every printing method. Knowing the strengths of each helps you make the most cost-effective decision: Digital printing is perfect for small batches, personalized runs, or multiple SKUs Offset printing is ideal for high-quality retail packaging in larger volumes Flexographic printing is budget-friendly for basic folding cartons or larger quantities with simpler designs ✅ Ensures print decisions align with volume, speed, and budget ✅ Reduces production delays and unexpected costs Final Thoughts Your folding carton is more than just a box—it’s your on-shelf sales rep, brand ambassador, and customer touchpoint all in one. Strategic use of print can transform ordinary packaging into a powerful marketing tool, helping you communicate, connect, and convert. Need help making your folding carton print work harder? We’ll help you choose the right design, layout, and print method to bring out the best in your packaging—without overcomplicating your process or budget. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Folding Carton Facebook Twitter LinkedIn Pinterest Relevant Posts