Home » Assessing Your Packaging Needs: A Buyer’s Guide

Assessing Your Packaging Needs: A Buyer’s Guide

For buyers across industries, determining the right packaging is a crucial aspect of product management. It’s essential to balance functionality, cost, aesthetic appeal, and sustainability. This guide provides an in-depth look at how buyers can effectively assess their packaging needs.

Understanding the Product Requirements

Proper packaging starts with a clear understanding of the product.

- Product Analysis: Evaluate the size, weight, fragility, and any special handling needs of the product. Consider environmental factors that may affect the product, like temperature or humidity.

- Target Market and Consumer Preferences: Understand the expectations of your target market. Keep abreast of trends, especially increasing preferences for sustainable packaging.

Evaluating Packaging Materials

The choice of materials can make or break your packaging strategy.

- Material Options: Compare materials like cardboard, plastic, glass, or metal. Consider factors like durability, cost, and environmental impact. Specialized materials might be necessary for certain products.

- Sustainability Considerations: Opt for environmentally friendly materials where possible and consider the full lifecycle of the packaging materials.

Design and Branding

Packaging is a critical aspect of your brand identity and marketing.

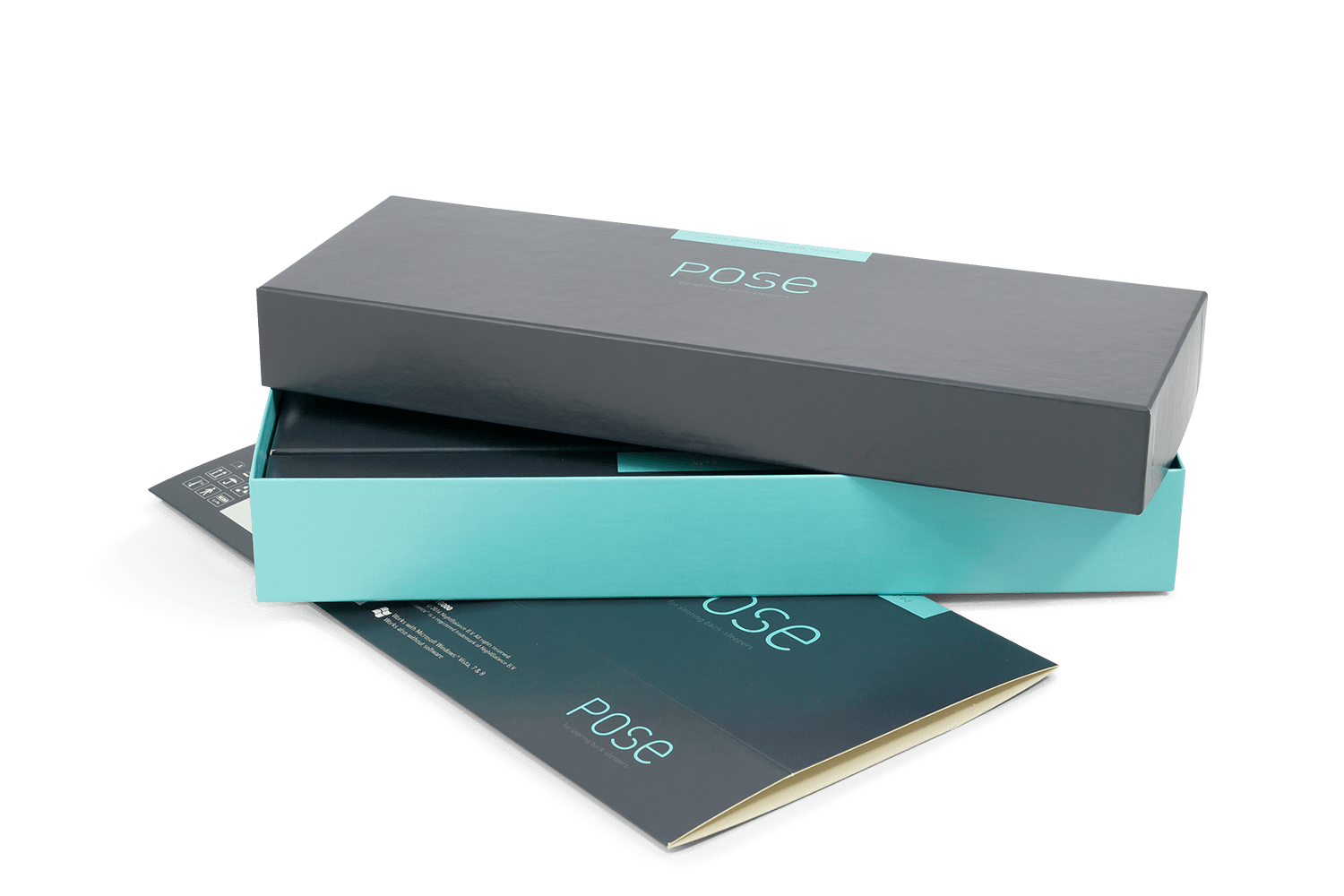

- Design Aesthetics: Ensure the packaging design is aligned with your brand and appeals to your target audience. The color scheme, typography, and imagery should reflect your brand’s values.

- Functionality and User Experience: Packaging should be user-friendly and offer a positive unboxing experience.

Cost Analysis

Understanding and managing the cost of packaging is crucial.

- Budgeting: Balance the cost of packaging with the need for quality and functionality. Consider long-term savings from durable or waste-reducing materials.

- Volume and Scalability: Assess how the quantity of packaging needed may change with your business’s growth.

Logistics and Supply Chain Management

Consider how packaging will impact the logistics of your product.

- Storage and Transportation: Evaluate the impact of packaging on storage and transportation costs.

- Supplier Selection: Choose suppliers based on quality, reliability, sustainability, and innovation.

Regulatory Compliance and Standards

Ensure your packaging meets all industry regulations and standards.

- Legal Requirements: Stay updated on laws and regulations, particularly for specific industries like food and pharmaceuticals.

Feedback and Continuous Improvement

Regularly assess your packaging and make improvements based on feedback.

- Collect Feedback: Use customer and stakeholder feedback to refine your packaging strategy.

If you are interested in accessing your packaging needs and require packaging, then partner with Brown Packaging today to get started.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Assessing Your Packaging Needs: A Buyer’s Guide

As 2025 approaches, the U.S. packaging industry faces a new reality with tariffs that aim to prioritize domestic sourcing and manufacturing. These changes could disrupt supply chains, increase costs, and reshape procurement strategies for packaging buyers. Preparing for these tariffs now can help businesses minimize challenges and capitalize on potential opportunities. Here’s a comprehensive guide to getting your packaging operations ready for the evolving landscape. Understanding the Impact of Tariffs on Packaging Tariffs are taxes on imported goods designed to encourage domestic production. While these measures can boost local manufacturing, they also bring challenges: Higher Costs for Imported Materials: Common materials like corrugated board, flexible plastics, and metals may become more expensive due to tariffs. Supply Chain Adjustments: Companies that rely on international suppliers must rethink their sourcing strategies to mitigate delays and costs. Uncertain Market Dynamics: Tariff-induced price changes may lead to shifts in supplier relationships and product availability. To stay competitive, packaging buyers need to adapt their processes, relationships, and strategies proactively. Strategies to Prepare for Tariffs Evaluate Your Current Supply Chain The first step in preparing for tariffs is understanding your current supply chain. Assess where your materials and products come from and identify potential tariff-affected areas. Key Questions to Ask: Are your suppliers located internationally or domestically? Which materials or products are likely to face tariff increases? What alternatives are available in the domestic market? This evaluation will help pinpoint vulnerabilities and guide your next steps. Strengthen Relationships with Domestic Suppliers Tariffs are expected to increase demand for U.S.-based packaging suppliers. Building strong relationships now can secure your position as a priority customer and ensure access to materials. Action Steps: Reach out to domestic manufacturers to discuss capacity and lead times. Negotiate long-term contracts to lock in pricing and availability. Explore local sourcing options for commonly used materials. Diversify Your Supplier Base Relying on a single supplier or region for your packaging needs can leave you vulnerable to tariff-related disruptions. Diversification ensures flexibility and reduces risk. How to Diversify: Identify backup suppliers both domestically and internationally. Split orders among multiple vendors to avoid over-reliance on one source. Work with distributors who can provide access to a variety of suppliers. Optimize Packaging Design Innovative packaging design can help reduce material costs and simplify production, making it easier to adapt to tariff-related changes. Design Adjustments to Consider: Lightweight: Use thinner or lighter materials to reduce overall costs. Simplified Components: Opt for mono-material designs that are easier to source domestically. Right-Sizing: Tailor packaging dimensions to minimize material waste. Focus on Cost Management Tariffs may increase expenses, but careful cost management can help offset their impact. Cost-Saving Measures: Consolidate orders to take advantage of bulk discounts. Streamline inventory management to avoid overstocking or last-minute purchases. Negotiate payment terms with suppliers to improve cash flow. Leverage Technology for Planning Advanced technology can provide valuable insights and improve decision-making during times of change. Useful Tools: Supply Chain Analytics: Identify risks and optimize sourcing strategies. Inventory Management Systems: Monitor stock levels and forecast future needs accurately. Tariff Calculators: Estimate the financial impact of tariffs on your materials and products. Stay Informed About Policy Changes Tariff policies can evolve, and staying updated is crucial to making informed decisions. Monitor industry news and maintain open communication with suppliers and trade associations. How to Stay Updated: Subscribe to packaging industry publications. Attend trade shows and seminars focusing on tariff and supply chain management. Build relationships with customs brokers and trade consultants for expert advice. Opportunities Amid the Challenges While tariffs may present hurdles, they also create opportunities for growth and innovation within the packaging industry: Domestic Sourcing Incentives: Strengthening local supply chains can reduce reliance on global markets and enhance long-term stability. Sustainability Improvements: Transitioning to local, eco-friendly materials can align with both regulatory requirements and consumer demand. Market Differentiation: Companies that adapt quickly can position themselves as reliable partners in the new tariff landscape. Action Plan for Packaging Buyers To prepare for tariffs effectively, packaging buyers should focus on the following: Conduct a Supply Chain Audit: Identify potential vulnerabilities and alternatives. Collaborate with Suppliers: Build strong relationships with domestic partners. Plan for Flexibility: Diversify suppliers and inventory to remain adaptable. Invest in Innovation: Optimize packaging design and explore cost-saving measures. Stay Proactive: Monitor policy updates and engage with industry experts. Conclusion Preparing for tariffs in 2025 requires strategic planning and proactive decision-making. By understanding their impact and taking steps to adapt, packaging buyers can mitigate risks and position their businesses for success. Whether it’s optimizing your supply chain, exploring new materials, or leveraging technology, the key is to act now and embrace the changes ahead. If you are interested in preparing or adjusting to tariffs for your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Selecting the right stretch film is essential for ensuring the stability, safety, and integrity of your products during storage and transit. Stretch film plays a crucial role in protecting products on pallets, minimizing damage, and reducing losses. Understanding the basics of stretch film and the specific needs of your application is key to making the right choice. To select the right stretch film for your application, you must consider the following factors: Load Type The Type of Product You Are Shipping Application Methods Cost Detailed Considerations When Selecting Stretch Film Load Type Understanding the type of load you are securing is crucial in selecting the appropriate stretch film. Loads can be categorized into three main types: Type A Loads: Uniform loads with straight edges that are similar in shape to the pallet. These loads are easier to wrap and are less prone to puncturing the film. Type B Loads: Loads with some irregular shapes or slightly overhanging edges which can challenge the film’s integrity and require more durable film to prevent tears. Type C Loads: Highly irregular loads with sharp edges or unstable stacking that pose the highest risk for puncturing and tearing. These require the strongest, most resilient films. Product Type and Weight The type of product and its weight influence the choice of stretch film: Light Loads: For products like tissues or paper goods, a lighter gauge film can suffice. Medium Loads: Products such as canned goods that weigh more but aren’t excessively heavy might need a medium gauge film for better performance. Heavy Loads: For items like bricks or chemicals, a heavy-duty film is necessary to accommodate the increased weight and potential shifting within the load. Application Methods The method of application significantly affects the type of stretch film needed: Hand Rolls: Best for low-volume packaging operations or where machinery is not feasible. Hand rolls are lighter and more manageable for manual application. Machine Rolls: Ideal for high-volume environments where machines can apply the film much faster and more consistently than manual applications. Cost Considerations Budget is always a concern, but balancing cost with quality is key: Economic Films: Typically thinner and less durable, suitable for light, uniform loads that require basic containment. Premium Films: More expensive, these films offer better stretch, durability, and puncture resistance for challenging load types. Special Product Requirements and Additives Depending on the specific needs of the products being shipped, different additives in stretch films can provide necessary protection: UV Protection: Essential for products exposed to sunlight during storage or transit to prevent degradation. Anti-Static Films: Crucial for electronic products to prevent static discharge during handling. Colored Films: Useful for coding shipments by destination or product type, enhancing organization and handling efficiency. Sustainability Options Consider environmentally friendly films that reduce the impact on the environment without compromising on quality or performance: Recycled Content Films: Made from post-consumer or post-industrial recycled materials. Biodegradable Films: Designed to break down more quickly than traditional plastics, reducing waste in landfills. Summary: Making the Right Stretch Film Choice To effectively select the right stretch film, you must analyze the load type and product characteristics to determine the film’s required strength and resistance. Consider the operational context, such as the volume of wrapping needed and whether it will be done manually or with machines. Balance your budget with the need for film performance to avoid over-spending or under-protecting your products. Evaluate any special requirements such as UV protection, anti-static properties, or color coding. Opt for sustainable options where possible to align with environmental goals. By thoroughly assessing these factors, you can choose a stretch film that not only meets your logistical requirements but also enhances the security and integrity of your shipments. For tailored solutions that match your specific needs, consulting with a professional packaging supplier like Brown Packaging can provide you with the expertise and product range to ensure optimal protection and performance. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Stretch Film Facebook Twitter LinkedIn Pinterest Relevant Posts

A rigid box, often referred to as a setup box, stands out in the packaging world due to its robust and durable design. Made from dense paperboard that is considerably thicker than the material used in standard folding cartons, rigid boxes are not just packaging but a statement of quality and luxury. They are fully customizable, often involving complex construction processes and high-quality materials, making them synonymous with premium branding and product presentation. Comprehensive Overview of Rigid Box Styles Rigid boxes are celebrated for their versatility and elegance in design. Here’s a deeper look into the various styles and their functional aesthetics: Two-Piece Box The quintessential model in rigid box design, the two-piece consists of a base and a lid. Simple yet elegant, this style is highly favored for its classic appearance and ease of use. It’s widely used across various industries, from high-end electronics to gourmet foods. Collapsible (Foldable) Innovative and practical, collapsible rigid boxes are designed to lay flat for economical storage and shipping, yet they can be easily assembled into a sturdy, structured box. This design is particularly favored by businesses looking to reduce logistical costs without compromising on packaging quality. Match (Slide) The match style features a tray that slides into a sleeve, offering a dynamic unboxing experience that is both smooth and engaging. It’s perfect for products that require an extra touch of interaction, such as artisanal gifts or bespoke jewelry. Book Mimicking the opening of a book, this style adds a narrative element to the packaging, enhancing the unboxing experience. It is ideal for special editions, collector’s items, or high-value publications. Magnetic Incorporating magnets for a secure and satisfying closure, magnetic boxes offer an upscale feel, often used for premium products such as designer accessories and luxury cosmetics. The magnets add a level of sophistication and functionality, ensuring the contents are safely enclosed. Learn more about magnetic boxes. Other Innovations Beyond these common types, rigid boxes can also be crafted with unique features like hinged/flip lids, shoulder/neck constructions, or even round shapes, tailored to specific product dimensions and brand aesthetics. Applications and Uses of Rigid Boxes Due to their sturdy construction and elegant appearance, rigid boxes are predominantly used for: High-End Electronics: Providing excellent protection and a premium unboxing experience for gadgets. Luxury Cosmetics: Enhancing the brand value and shelf presence of beauty products. Fine Jewelry: Offering a secure and attractive packaging solution that matches the item’s luxury. Gifts and Specialties: Making occasions more memorable through beautifully designed packaging. Advantages of Choosing Rigid Boxes Choosing a rigid box for your product packaging brings several benefits: Enhanced Product Protection: The sturdy construction ensures that contents are well-protected against impacts and compression. Elevated Brand Perception: The quality and elegance of rigid boxes enhance the perceived value of the contents, influencing customer satisfaction and loyalty. Customization Opportunities: From size and shape to finishes and printing techniques, every aspect can be tailored to create a unique packaging solution that reflects the brand’s identity. Sustainable Options: Many rigid boxes can be produced using recycled materials and can be recyclable themselves, aligning with eco-friendly brand values. Key Considerations for Rigid Box Packaging While rigid boxes offer unparalleled elegance and protection, they come with considerations that may impact their suitability: Cost: The premium materials and customized manufacturing processes can make rigid boxes more expensive than other types of packaging. Practicality: For some products, especially those that are low-cost or require frequent access, a rigid box may not be the most practical choice. Minimum Order Quantities: Custom rigid box manufacturers often require large minimum orders, which can be a barrier for smaller businesses or those requiring limited runs. Conclusion: The Strategic Value of Rigid Boxes Rigid boxes are not just packaging; they are a strategic tool for enhancing brand prestige and improving customer experience. They are best suited for products that require a high level of protection or brands aiming to make a strong impact on the market. With the ability to fully customize the design and features, rigid boxes offer a packaging solution that truly stands out. If you are considering this type of packaging, partnering with a specialized provider like Brown Packaging will ensure that your packaging not only meets your aesthetic and functional needs but also aligns with your strategic branding objectives. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Rigid Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts