Home » Why Size and Strength Matter in Corrugated Boxes

Why Size and Strength Matter in Corrugated Boxes

Corrugated boxes, commonly referred to as cardboard boxes, are a ubiquitous presence in our day-to-day lives. From moving houses to shipping products, these boxes are employed in a myriad of applications. As varied as their uses are, so are the demands placed upon them. Two critical factors dictate the effectiveness of a corrugated box: its size and its strength. Let’s delve deep into why these aspects are so important.

Ensuring the Right Fit

Protecting Contents

An appropriately sized box ensures that the products inside do not jostle or shift significantly during transit. If a product is moving freely within a box, it’s more susceptible to damage from impacts or sudden movements.

Efficient Space Utilization

Especially when it comes to storage or shipping, using boxes of the correct size ensures maximum utilization of available space, whether in a warehouse or a shipping container. Overly large boxes waste space, while small ones may necessitate the use of multiple boxes where one might have sufficed.

Cost Efficiency

Using the right-sized box can save costs. Employing a box larger than necessary implies more material usage and potentially increased shipping costs based on dimensional weight pricing.

Strength to Withstand Pressure

Material Composition

The strength of a corrugated box is primarily determined by the composition and configuration of its corrugated fibers. There are various flute sizes, with larger flutes providing more cushioning and smaller ones offering better printability and foldability.

Stacking Strength

When boxes are stacked, especially in storage or during shipping, the strength of the box determines how much weight it can bear without collapsing. A box with appropriate strength will ensure that the contents are not crushed, regardless of its position in a stack.

Environmental Protection

A sturdy corrugated box can provide some protection against environmental factors like humidity or minor water exposure. The corrugated design, combined with certain coatings or treatments, can help resist moisture infiltration.

Balancing Strength with Weight

While strength is essential, it’s also crucial to consider the weight of the box. Overly thick or heavy boxes can increase shipping costs and may be overkill for certain lightweight items. The strength-to-weight ratio is thus a crucial aspect when determining the best box for the job.

Sustainability Considerations

Today, environmental concerns play a significant role in packaging decisions. Corrugated boxes are favored because they are often made from recycled material and are recyclable themselves. By ensuring that a box is neither too big nor stronger than necessary, resources are conserved, and waste is minimized, contributing to a more sustainable packaging solution.

Conclusion

When selecting a corrugated box, one must consider both size and strength in conjunction to ensure the safety of its contents, cost-efficiency, and optimum space utilization. With the rising emphasis on sustainability, it’s also crucial to choose boxes that align with environmental goals. Whether you’re a business owner or simply moving to a new house, understanding the significance of these factors can make a world of difference in your packing and shipping endeavors.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Why Size and Strength Matter in Corrugated Boxes

Why Custom Corrugated Boxes Remain a 2026 Essential Custom corrugated boxes continue to be the most relied-on packaging solution for industries ranging from industrial manufacturing to ecommerce. But in 2026, the focus is shifting from basic box customization to engineered performance, material precision, and automation-ready design. Buyers are no longer just sourcing packaging—they’re optimizing it for speed, cost, and product protection. Whether you’re buying corrugated boxes for shipping, retail display, or product kitting, here’s what to expect this year. Structural Design Is Driving the New Definition of Custom In 2026, “custom corrugated packaging” means more than just size and print—it’s about functional structure. Businesses are prioritizing right-size engineering to cut down on void fill, improve stacking, and reduce damage Popular designs like multi-depth RSCs, auto-lock bottoms, and dual-SKU shipper trays are growing Custom inserts and internal supports are being integrated into the box structure itself—not as separate packaging steps If you’re shipping high-value or odd-shaped products, expect 2026 solutions to emphasize built-in protection and packaging efficiency. Corrugated Material Selection Is More Technical Than Ever Rising board costs and stricter sustainability requirements are reshaping how materials are specified. Clients are now choosing corrugated by ECT, puncture rating, and flute profile, not just by thickness Recycled and virgin content blends are being optimized based on weight, moisture exposure, and destination Lighter-weight corrugated is being reinforced through design (edge wraps, folded ribs, etc.), not just thicker walls This year, your corrugated box’s performance will come more from material science + structure than brute strength. Automation Compatibility Is a Procurement Priority Packaging that doesn’t run smoothly on automated lines is a liability. In 2026: Buyers are demanding machine-compatible corrugated formats, with tolerances that support automated erecting, loading, and sealing Expect growth in auto-bottom boxes, precise glue flap alignment, and barcode-friendly panel design Custom boxes are being designed in tandem with fulfillment processes—not retrofitted afterward For high-volume shippers, compatibility with WMS and automation systems is now a core spec—not an afterthought. Custom Corrugated Boxes Are Becoming Data-Driven Sustainability Tools 2026 sustainability goals are technical, not theoretical. Corrugated boxes are being selected for FSC or SFI certification, recyclability scores, and regional sourcing proximity Life cycle assessment (LCA) data is being requested by major retailers and procurement teams Minimalist branding, lighter flutes, and efficient structural design are all being used to cut carbon, not just cost Sustainability is part of how your box is measured—so make sure it’s part of how it’s designed. Built-In Branding, Not Just Printed Logos While most custom corrugated boxes—especially RSC formats—still use single-color flexo print, more are evolving to support multi-SKU visibility, inventory control, and regulated handling. Expect wider use of label panels, QR codes, and internal printing for ease of returns and fulfillment High-end retail corrugated (especially for appliances or electronics) will see more use of digital or lithographic labels Structural design now plays a role in branding—form, function, and fit are part of how buyers perceive value Your corrugated box is part of the product experience, even if it’s headed for a warehouse—not a retail shelf. Conclusion: Corrugated in 2026 Is a Strategic Advantage If you’re still buying boxes by the spec sheet, you’re missing opportunities to improve speed, reduce damage, and increase operational efficiency. In 2026, custom corrugated boxes are no longer just a container—they’re part of your business infrastructure. Whether you’re focused on industrial logistics, subscription fulfillment, or protecting high-value goods, now is the time to reassess your packaging. Brown Packaging helps brands design fully customized corrugated solutions that align with your cost targets, sustainability goals, and logistics requirements. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to storage optimization, one might not immediately think of corrugated boxes as a viable solution. However, corrugated boxes have shown to be one of the most practical and cost-effective ways to store, transport, and protect various items. In this post, we’ll delve into how you can optimize your storage space with these versatile containers. Understanding Corrugated Boxes Before we start it is essential to understand what corrugated boxes are and why they make excellent storage solutions. Corrugated boxes are made from corrugated paperboard that has a row of flutes sandwiched between two liners. The presence of these flutes gives these boxes their distinct sturdiness, making them suitable for holding various items. They are lightweight, yet robust, offering excellent protection and ease of transport. Benefits of Using Corrugated Boxes for Storage Corrugated boxes are an eco-friendly and sustainable storage solution. They are recyclable and made from a renewable resource. Moreover, they are cost-effective, customizable, and adaptable to different shapes, sizes, and requirements. They offer an ideal balance between strength and weight, ensuring the protection of the stored items. How to Optimize Storage Space with Corrugated Boxes Now that we have a basic understanding of corrugated boxes and their benefits, let’s delve into how you can optimize your storage space using these boxes. Choose the Right Size and Shape Corrugated boxes come in various sizes and shapes. When optimizing storage space, choosing the right size is crucial. Remember, a box that’s too big will consume more storage space, while a box that’s too small might not adequately protect your items. To optimize space, consider the size and shape of the items you wish to store. Choose a box that will snugly fit your items without wasting space. If you have multiple items of different shapes and sizes, consider getting multiple boxes of various sizes to ensure each item fits well. Customize the Internal Layout One of the benefits of corrugated boxes is their customizability. By adding dividers or partitions, you can create separate compartments within a single box. This is particularly useful when storing multiple smaller items in one box, as it allows you to make the most of the available space, keeping items organized and reducing the risk of damage. Stack Them Effectively Corrugated boxes are designed to be stackable, which is a key advantage when optimizing storage space. When stacking boxes, ensure heavier boxes are at the bottom, and lighter ones are on top. Also, remember not to over-stack boxes, as this can compromise their structural integrity and risk damaging the stored items. Use Labels and Markings While not directly related to optimizing physical space, using labels and markings can significantly improve your storage efficiency. Clearly marking what’s in each box will save you time searching for items and will make the storage system more effective. Best Practices for Storage Optimization with Corrugated Boxes Now, let’s review some best practices for storage optimization with corrugated boxes. Regularly Audit Your Storage Perform regular audits of your stored items. This way, you’ll be aware of what you have and where it is, making retrieval easier and storage more efficient. Reuse and Recycle Boxes Corrugated boxes are sturdy and durable, meaning they can be reused multiple times. Once a box is no longer needed for one set of items, it can be repurposed for another. Invest in Quality While corrugated boxes are generally durable and strong, not all are created equal. It’s essential to invest in quality corrugated boxes, as they will last longer and provide better protection for your stored items. Poor quality boxes may collapse under weight or wear out faster, leading to ineffective storage and potential damage to your items. Innovative Corrugated Box Storage Solutions Apart from the traditional ways of using corrugated boxes for storage, there are some innovative solutions that you can adopt to maximize your storage space. Using Corrugated Storage Bins Corrugated storage bins are an excellent solution for storing and organizing small parts or products. These bins can be stacked or used with shelving units, optimizing your storage space. They come in various sizes, and their front opening provides easy access to the stored items. Bulk Cargo Boxes for Larger Items If you need to store larger items, bulk cargo boxes or gaylord boxes are an excellent solution. These corrugated boxes can hold large, heavy items while making the best use of your storage space. If you are interested in optimizing your corrugated boxes to your storage space, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

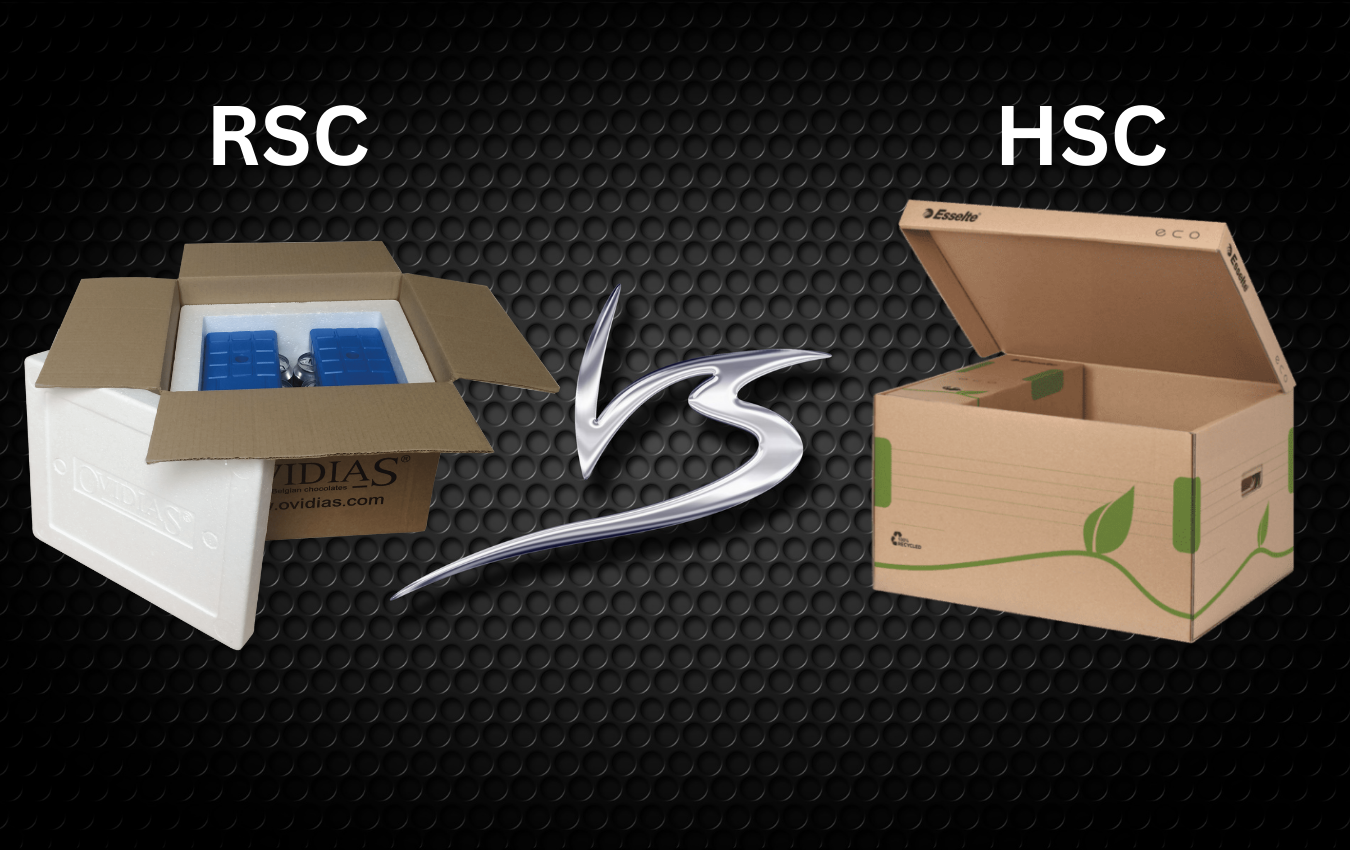

Packaging is an essential component of product marketing, as it not only protects the products but also helps in promoting them. Boxes are the most common type of packaging material used by businesses of all sizes, and there are several types of boxes available in the market, including regular slotted containers (RSC) and half slotted containers (HSC). Quick Overview: RSC Vs HSC Boxes In this blog, we will compare and contrast RSC and HSC boxes in order to help you select the right one for your business needs. Definitions Customization Options Features Benefits Advantages Applications How to Select the Right Box for Your Business Needs We will also provide guidance on how a packaging buyer can select the appropriate type of box for their business needs. Definitions Regular slotted containers (RSC) are the most common type of box used in packaging. They are made from a single sheet of corrugated cardboard that is cut and scored to create four flaps at the top and bottom of the box. The flaps are then folded and sealed with tape to form the box. RSC boxes are versatile and can be used for a variety of products. Half slotted containers (HSC) are similar to RSC boxes but only have one set of flaps, which are located at the top of the box. The bottom of the box is left open, which makes it ideal for larger products or products that require loading from the top. HSC boxes are also versatile and can be used for a variety of products. Customization Options Both RSC and HSC boxes can be customized to meet specific business needs. Businesses can choose the size, shape, and thickness of the cardboard used to create the boxes. They can also choose to print logos, product information, and other graphics on the boxes to enhance their branding. Features RSC boxes are designed to be sturdy and secure, with four flaps that provide extra protection for the product inside. They can be stacked on top of each other without collapsing, which makes them ideal for shipping and storage. HSC boxes, on the other hand, are designed to be open at the bottom, which makes them easier to load and unload. They are also lighter than RSC boxes, which makes them more cost-effective to ship. Benefits RSC boxes are versatile and can be used for a variety of products. They are also strong and durable, which makes them ideal for shipping and storage. They are also cost-effective and can be easily stacked, which saves space and reduces transportation costs. HSC boxes are ideal for larger products or products that require loading from the top. They are also lightweight and cost-effective to ship. They are also easier to load and unload, which saves time and reduces labor costs. Disadvantages RSC boxes are not as easy to load and unload as HSC boxes, which can increase labor costs. They are also not suitable for products that require loading from the top. HSC boxes are not as secure as RSC boxes, as they only have one set of flaps at the top. This can make them less suitable for products that require extra protection during shipping and storage. Applications RSC boxes are ideal for a variety of products, including electronics, food and beverage products, and household items. They are also commonly used in the e-commerce industry, as they are cost-effective and easy to stack. HSC boxes are ideal for larger products, such as appliances, furniture, and industrial equipment. They are also commonly used in the agriculture industry, as they are lightweight and easy to load and unload. How to Select the Right Box for Your Business Needs When selecting the appropriate type of box for your business needs, there are several factors to consider. These include: Product Size and Weight: If you are shipping large or heavy products, an HSC box may be more suitable, as it provides easy access for loading and unloading. However, if your product is smaller and requires more protection, an RSC box may be the better option. Protection Needs: If your product requires extra protection during shipping and storage, an RSC box may be more suitable, as it has four flaps that provide extra protection. However, if your product is less fragile, an HSC box may be a more cost-effective option. Shipping and Storage Needs: If you are shipping or storing products in large quantities, an RSC box may be more suitable, as it is stackable and saves space. However, if you have limited storage space or are shipping smaller quantities, an HSC box may be more suitable. Budget: Both RSC and HSC boxes are cost-effective options for packaging, but the price may vary depending on the size and customization options chosen. Consider your budget when selecting the appropriate type of box for your business needs. Summary: RSC Vs HSC Boxes In conclusion, both regular slotted containers (RSC) and half slotted containers (HSC) have their own unique features, benefits, and disadvantages. When selecting the appropriate type of box for your business needs, consider factors such as product size and weight, protection needs, shipping and storage needs, and budget. If you are interested in corrugated boxes such as RSC, HSC or alternatives, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts