Home » The Role of Packaging Products in Corrugated Box Applications

The Role of Packaging Products in Corrugated Box Applications

Corrugated boxes play a vital role in the packaging industry, offering durability and versatility for shipping and storing various products. To ensure the safe transportation and identification of goods, packaging products such as tape, stretch film, labels, inserts, void fill, dunnage bags, bubble wrap, edge protectors, and shrink wrap are commonly used in conjunction with corrugated boxes.

Quick Overview: Packaging Products for Corrugated Boxes

In this blog post, we will explore the significance, applications, and benefits of utilizing these packaging products with corrugated boxes.

Tape

Tape is an essential packaging product used to secure corrugated boxes, ensuring the products inside remain protected during transit. It comes in various materials, including plastic, paper, and cloth. Plastic tape is widely used due to its cost-effectiveness and strong sealing properties, while paper tape offers an eco-friendly option with a natural appearance. Cloth tape is ideal for heavy-duty packaging requirements.

Benefits of using tape with corrugated boxes include:

- Protection: Tape securely seals corrugated boxes, safeguarding the products during transportation.

- Customization: Tape can be tailored to fit different sizes and shapes of corrugated boxes.

- Convenience: Tape is easy to use and can be applied manually or with a tape dispenser.

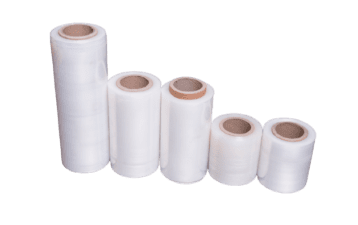

Stretch Film

Stretch film is a versatile packaging product used to provide an additional layer of protection to corrugated boxes. It safeguards products from dust, moisture, and other environmental factors during transit, while also minimizing product movement.

Benefits of using stretch film with corrugated boxes include:

- Protection: Stretch film offers an extra layer of protection for products during transportation.

- Customization: Stretch film can be customized to fit various sizes and shapes of corrugated boxes.

- Convenience: Stretch film can be applied manually or with specialized machines.

Labels

Labels play a crucial role in identifying the contents of corrugated boxes and providing essential information about the products. They can indicate the box contents, product weight, handling instructions, and branding details.

Benefits of using labels with corrugated boxes include:

- Identification: Labels provide vital information about the products inside the boxes.

- Customization: Labels can be designed and customized to fit specific labeling requirements.

- Convenience: Labels can be easily affixed to corrugated boxes manually or using labeling machines.

Inserts

Inserts are employed to protect products within corrugated boxes, preventing movement and minimizing the risk of damage during transportation. Common materials used for inserts include foam, cardboard, and plastic.

Benefits of using inserts with corrugated boxes include:

- Protection: Inserts provide additional protection by securing products in place during transit.

- Customization: Inserts can be tailored to fit the shape and size of corrugated boxes.

- Convenience: Inserts are easy to use and can be manually placed within the boxes.

Void Fill

Void fill is used to occupy empty spaces within corrugated boxes, reducing product movement and enhancing protection. It is particularly useful for fragile items such as glassware, electronics, and ceramics. Void fill materials include paper, foam, and inflatable plastic.

Benefits of using void fill with corrugated boxes include:

- Protection: Void fill prevents products from shifting and minimizes the risk of damage during transportation.

- Customization: Void fill can be adjusted to fit the specific box size and shape.

- Convenience: Void fill is easy to use and can be manually placed within corrugated boxes.

Bubble Wrap

Bubble wrap is a popular packaging product known for its cushioning properties, making it suitable for protecting delicate items such as glassware, electronics, and ceramics. It consists of plastic material with air bubbles.

Benefits of using bubble wrap with corrugated boxes include:

- Protection: Bubble wrap provides effective cushioning and safeguards fragile products during transportation.

- Customization: Bubble wrap can be cut to fit the size and shape of the products and boxes.

- Convenience: Bubble wrap is easy to use and can be wrapped around products manually.

Edge Protectors

Edge protectors are designed to protect the corners and edges of products within corrugated boxes. They are commonly used for items like furniture, appliances, and electronics.

Benefits of using edge protectors with corrugated boxes include:

- Protection: Edge protectors prevent damage to product corners and edges during transportation.

- Customization: Edge protectors can be customized to fit various box sizes and shapes.

- Convenience: Edge protectors are easy to use and can be manually applied.

Shrink Wrap

Shrink wrap is a packaging product used to secure and protect products within corrugated boxes during transportation. It involves wrapping a plastic film around the products and applying heat to shrink and conform it to their shape.

Benefits of using shrink wrap with corrugated boxes include:

- Protection: Shrink wrap provides secure and tamper-evident packaging, protecting products from external elements.

- Customization: conforms to the shape of products and corrugated boxes.

- Convenience: can be easily applied manually or with shrink wrap semi or fully automatic machines.

If you are interested corrugated boxes or other types of packaging, then partner with Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » The Role of Packaging Products in Corrugated Box Applications

Understanding One-Piece FOL and Three-Piece Bike Shipping Boxes Choosing the right box style is essential when shipping bicycles—especially for brands, manufacturers, and distributors focused on

Selecting the right packaging supplier is a strategic decision that significantly impacts various facets of a business. From influencing brand perception to managing costs and

As tariffs take effect in 2025 to promote domestic sourcing, the packaging industry in the United States is set to experience notable cost changes. While