Home » How to Maximize Efficiency with Mailing Tubes in Your Shipping Process

How to Maximize Efficiency with Mailing Tubes in Your Shipping Process

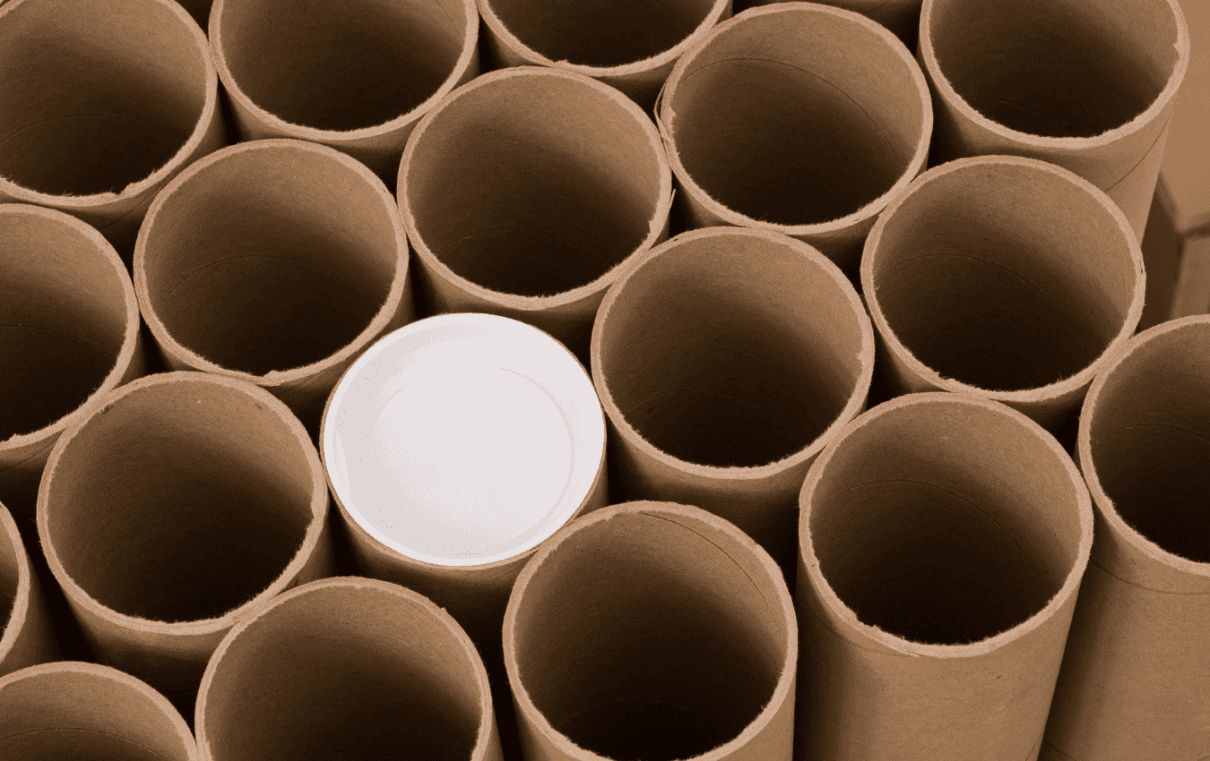

Shipping is a critical part of any business that provides physical goods to its customers. Efficient, cost-effective shipping processes not only improve customer satisfaction but also drive down operational costs. Mailing tubes, while not a new concept, have been an underutilized resource in many industries. They can optimize shipping costs, enhance product safety, and offer unique branding opportunities. In this blog post, we will delve deep into the world of mailing tubes and provide actionable tips on how to maximize their efficiency in your shipping process.

Understanding the Advantages of Mailing Tubes

Before we discuss how to make the most of mailing tubes, let’s first understand their unique advantages:

- Durability: Mailing tubes are typically made from sturdy materials such as cardboard or plastic, making them resistant to damage from drops or impact. This provides excellent protection for the shipped items.

- Shape and Design: The cylindrical shape of mailing tubes distributes pressure evenly across the surface, making it less likely that the contents will be crushed or damaged during transportation.

- Versatility: Mailing tubes can accommodate a wide array of items. They’re not just for posters or blueprints; many products such as apparel, accessories, or certain types of homeware can be rolled or strategically placed within these tubes.

- Economical: Due to their shape, mailing tubes often more economical for some shipping applications. Additionally, the simple design reduces the need for additional packing materials, saving money on both ends.

- Environmentally Friendly: Most mailing tubes are made from recyclable materials, making them a more sustainable choice for eco-conscious businesses and customers.

Maximizing Efficiency with Mailing Tubes: A Step-By-Step Guide

Now that we understand why mailing tubes are a fantastic option let’s explore how you can incorporate them effectively into your shipping process.

Step 1: Select the Right Size

Choosing the right size mailing tube is crucial to prevent damage and unnecessary costs. The tube should be slightly longer than the longest item you’re shipping and wide enough to accommodate all items without forcing them. However, avoid selecting a tube that’s excessively large, as it may lead to higher shipping costs or allow items to move around, potentially causing damage.

Step 2: Opt for Adjustable Length Tubes

One way to streamline your shipping process and reduce inventory is by choosing adjustable length mailing tubes. These tubes can be shortened or lengthened depending on the items being shipped, making them a versatile solution that reduces the need for a variety of tube sizes.

Step 3: Use Protective Inner Packaging

Though mailing tubes are durable, it’s still necessary to secure fragile items with protective packaging materials. Bubble wrap, packing peanuts, or foam can provide an extra layer of protection. However, remember to balance this with the need to keep weight and costs down.

Step 4: Ensure Secure Closure

To maximize the protection offered by the mailing tube, it’s vital to ensure its securely sealed. Whether you’re using end caps, friction-fit plugs, or tube crimping, be sure that both ends are tightly closed to prevent the contents from slipping out during shipping.

Step 5: Maximize Branding Opportunities

Mailing tubes present a unique canvas for your branding efforts. Customizing tubes with your logo, brand colors, or other designs can serve as an excellent marketing tool while enhancing the unboxing experience for your customers.

Step 6: Leverage Bulk Shipping Discounts

Many carriers offer discounts for businesses that ship in bulk. If you use mailing tubes regularly, consider consolidating your shipments to qualify for these reduced rates. It’s a simple way to drive down your shipping costs further.

Conclusion

Mailing tubes offer a host of benefits that can greatly enhance your shipping process. By selecting the right size, using protective packaging, securing closures, maximizing branding opportunities, and leveraging bulk shipping discounts, you can optimize your shipping process, reduce costs, and boost customer satisfaction. Don’t overlook the humble mailing tube; it might just be the shipping solution you’ve been seeking.

If you are interested in custom or stock mailing tubes, then partner with Brown Packaging today to get started.

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In

Home » How to Maximize Efficiency with Mailing Tubes in Your Shipping Process

Before committing to a full production run, businesses often receive packaging samples to evaluate fit, functionality, print quality, and overall design. Whether it’s a digital

In the world of e-commerce and supply chain management, the need for reliable packaging materials cannot be overstated. From the careful encasing of fragile items

A Full Overlap (FOL) box is a type of corrugated shipping box where the flaps fully overlap each other when closed, providing additional strength and